Barite Grinder

MGW series high efficiency pendular mill is used in different industries, such as mining, metallurgy, building materials, chemical industry etc.

Introduction of Barite Grinder

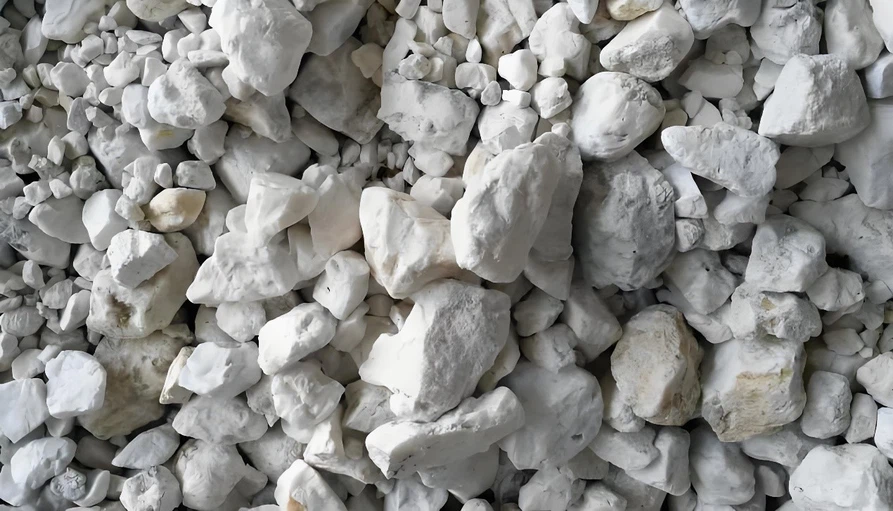

MGW series high efficiency pendular mill is used in different industries, such as mining, metallurgy, building materials, chemical industry etc. It can grind limestone, marble, barite, gypsum, graphite and other non-inflammable material. The material should be non-explosive mineral, with Mohs hardness below 9 and humidity lower than 6%.

Application of Barite Grinder

Barite is a non-metallic mineral, with main component barium sulfate. The ground barite powder has a wide range of applications, such as, drilling mud weighting agent, industrial filler (fillers for paint, paper, rubber, etc.), cement industry mineralizer, and various barium compounds.

We MR have done many grinding barite projects with MGW series grinders. Today we will introduce you one of them.

Barite Powder Processing Flow

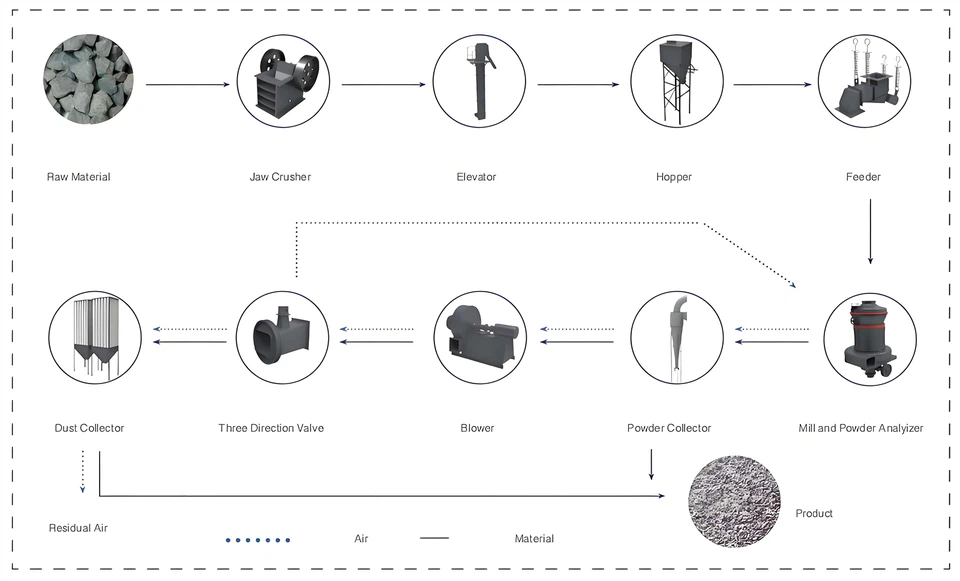

Stage 1: Large barite stones are transported to the raw material hopper by vehicles, then transferred to the jaw crusher by forklifts/manual labor to be crushed. Jaw crusher will crush them into the size that can enter the grinding equipment.

Stage 2: The crushed barite is transported to the bin by bucket elevator, then the belt feeder will send the material evenly and quantitatively into the grinder.

Stages 3: The ground barite powder is classified by the classifier after being ground. The unqualified powder will return to the mill for re-grinding.

Stages 4: The qualified barite powder flows with the airflow through the pipeline into the collector for separation and collection. The collected fine barite powder like 200 mesh or 300 mesh is discharged from the outlet by the conveying device, then, it will be sent to the final product bin or storage tank for packaging.

Technical Parameters of Barite Grinder

Name & Model | MGW110 | MGW138 | MGW175 | MGW198 |

Roller qty. (pieces) | 4 | 4 | 4/5 | 4/5 |

Outer diameter*height of roller (mm) | Φ360*190 | Φ460*240 | Φ580*280/ Φ520*280 | Φ620*300/ Φ520*300 |

Inner diameter*height of ring (mm) | Φ1100*190 | Φ1380*240 | Φ1750*280 | Φ1980*300 |

Main shaft speed (rpm) | 120 | 96 | 75 | 70 |

Max.feeding size (mm) | <30 | <35 | <40 | <50 |

Output size (mm) | 1.6-0.038 | 1.6-0.038 | 1.6-0.038 | 1.6-0.038 |

Capacity (t/h) | 3.5-10 | 6.5-15 | 13-20 | 15-30 |

Overall dimension (mm) | 8625*7933* 8642 | 9860*8340* 10227 | 13500*11500* 9500 | 15500*12000* 15000 |

Main mill motor (kw) | 55 | 110 | 185 | 280 |

Classifier motor (kw) | 11 | 22 | 37 | 55 |

Blower motor (kw) | 55 | 110 | 200 | 280 |

Jaw crusher | PE250*400 | PE250*750 | PE250*750 | PE250*1200 |

Jaw crusher motor (kw) | 22 | 22 | 22 | 37 |

Bucket elevator | TH200*9M | TH315*9.55M | TH315*11.02M | TH400*12.5M |

Bucket elevator motor (kw) | 3 | 4 | 4 | 7.5 |

Belt feeder (mm) | QB400*2500 | QB500*3000 | QB500*3000 | QB500*6000 |

Belt feeder motor (kw) | 1.5 | 3 | 4 | 4 |

Air block feeder | GF-Φ400 | GF-Φ500 | GF-Φ500 | GF-Φ500 |

Air block feeder motor (kw) | 2.2 | 4 | 5.5 | 5.5 |