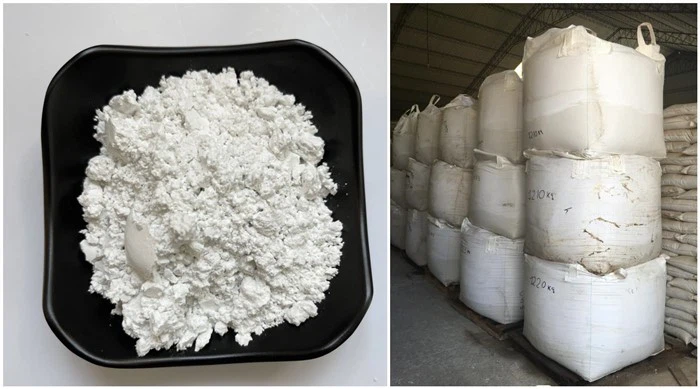

Dolomite Ultrafine Grinding Mill

Our ultra-fine grinding mill can help you to grind non-metallic minerals to 325-2500 mesh ultra-fine powder, while maximizing production rates and minimizing overall operational costs.

Introduction

While grinding applications may differ, the desired end result is often the same-achieving the finest particle size while maximizing production rates and minimizing overall operational costs. Our ultrafine grinding mill can help you make it happen, because it can help you grind non-metallic minerals to 325-2500 mesh ultrafine powder.

Application

| Material | Fineness (Mesh) | Application |

|

Dolomite

|

600 | Coating, paper making toothpaste, healing drugs and daily chemical using, pvc making, etc. |

| 800 | Paint, coating, paper making toothpaste, healing drugs and daily chemical using, pvc making, etc. | |

| 1250 | Paint, coating, paper making, toothpaste, healing drugs and daily chemical using.

additive in chemical and plastic high quality paper and seal oil as additive, etc. |

|

| 1500 | Paint, coating, paper making, toothpaste, healing drugs and daily chemical using.

additive in chemical and plastic high quality paper and seal oil as additive, etc. |

How Can Ultrafine Grinding Mill Grind Dolomite To Micro Powder?

Size Reduction Mechanisms

Grinded by rollers and rings, separated by classifier with frequency converter, all these key parts can help to achieve much smaller particle sizes than other mills.

High Efficiency, Less Operating Costs

Ultrafine grinding results are achieved with a lower energy power consumption and higher capacity of final product in comparison with other Mills.

Adjustable Grinding Fineness

The classifier has a frequency converter, which can adjust the speed of classifier, thus you can adjust the fineness of output size according to your need.

Sample Plant

Location: South America

Raw material: Dolomite

Input size: 200mm

Output size: 1250 mesh

Time of operation: 12 hours per day

Model of ultrafine grinding mill: MSF1000

Capacity: 2.1-2.5 tons per hour

Maintenance And Precautions

1. It is strictly forbidden for metal objects to enter the machine during the production of micro powder mill, so as to avoid danger and damage to the machine parts.

2. The minimum length of the dust-proof bag should not be less than 2 meters, and it should be shaken frequently during use to ensure good ventilation.

3. The micro powder mill should always check whether the bolts of each part are loose, so as to ensure the normal operation of the unit.

4. The start-up sequence of the micropowder mill is to turn on the fan first, then the main engine, and the opposite is true when the machine is shut down.