Calcium Carbonate Raymond Mill for Paint Industry

The Raymond mill drives the grinding roller to rotate through the motor, grinding the calcium carbonate stones inside the mill into the final product of calcium carbonate powder with uniform fineness. Due to the high purity and chemical stability of calcium carbonate powder, it plays a huge role in the paint industry.

MGW Raymond Mill

Recently, our MR sales department and after-sales technical department visited dozens of Raymond mill customers. We received feedback from customers that the calcium carbonate ground by our MR Raymond mill has more advantages and is easier to sell when sold to their customers in the paint industry. For example, the paint manufacturer “Nippon Paint” praised the quality of the calcium carbonate powder ground by the MR Raymond mill. They commented: Compared with other brands of Raymond mills, the calcium carbonate ground by the MR Raymond mill is not only higher in purity and more affordable, but also can improve the viscosity and stability of the paint to a higher level.

In fact, the purity of calcium carbonate is crucial to the quality of paint. The higher the purity, the better the hiding power, adhesion and durability of the paint. During the grinding process, our Raymond mill can accurately control the fineness of the powder, reduce the mixing of impurities, and operate stably through unique design and technology, which is both worry-free and efficient. So, why can our Raymond mill grind calcium carbonate with higher purity and higher whiteness?

Advantage

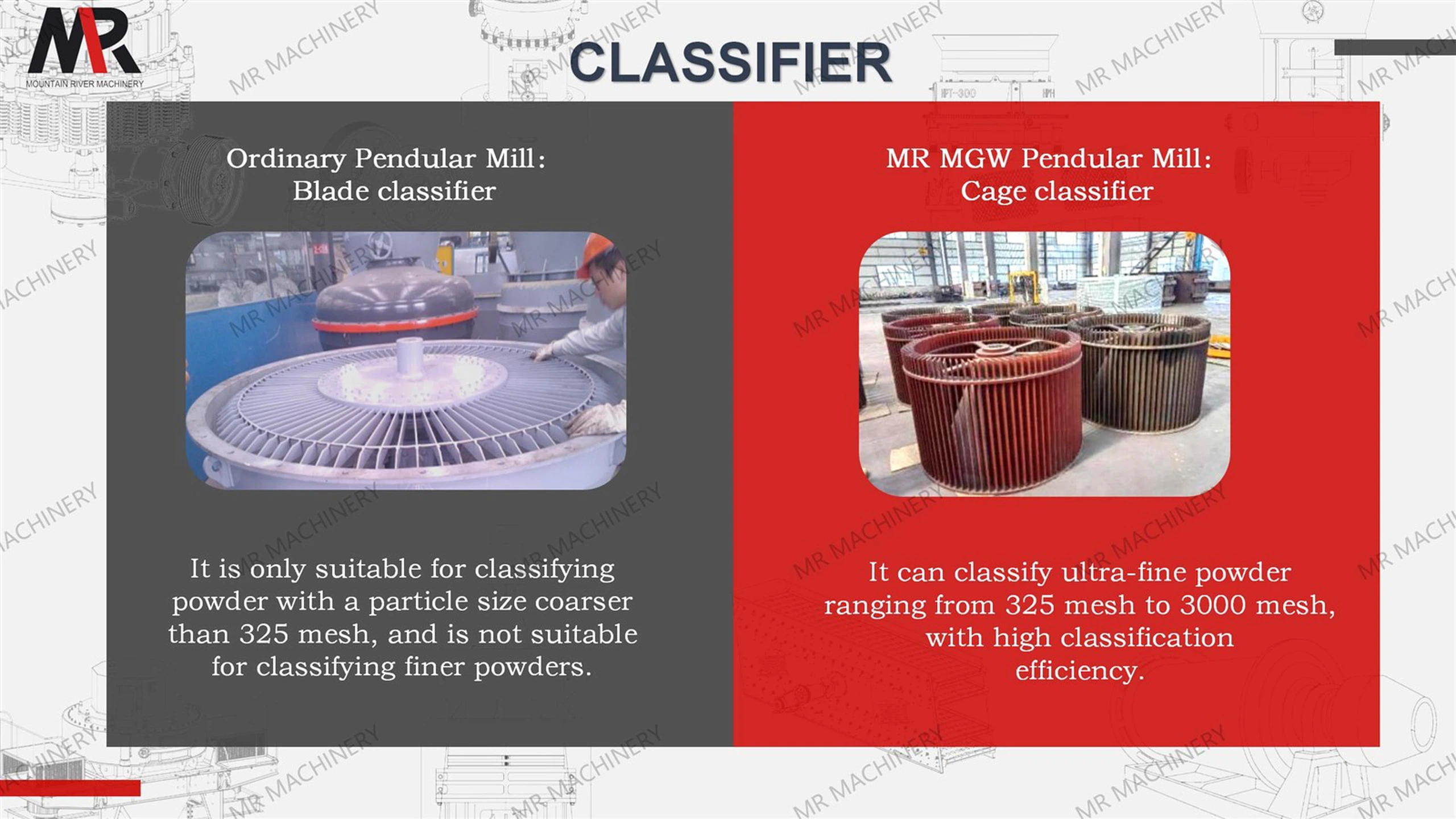

1. Use a grading cage classifier to screen powder

Compared with the traditional blade classifier, the MR classifier can screen out powder with finer particle size, which can improve the surface smoothness and gloss in the paint, ensure uniform dispersion, and avoid abnormal viscosity or sedimentation of the paint.

2. Use permanent magnetic roller belt conveyor to absorb metal debris and use high-quality plates to prevent metal debris from falling

The MR mill improves the purity of calcium carbonate through two key designs during the grinding process:

The first is the use of permanent magnetic roller belt conveyor, which can absorb metal debris when transporting small stones and reduce impurities entering the mill.

The second is to use more wear-resistant plates to avoid metal debris during the grinding process. This will make the calcium carbonate purer, better whiteness and brightness when used in paint, stronger covering power, and more beautiful coating.

FEEDER

Ordinary Raymond Mill:

Electromagnetic vibrating feeder

- Without permanent magnetic iron removal roller.

- Unable to remove iron.

- Unable to feed at a uniform speed.

MR MGW Raymond Mill:

Belt feeder with permanent magnetic iron removal roller

- With permanent magnetic iron removal roller

- Remove iron blocks from the material and protect the mill efficiently.

- Three-speed uniform feeding: fast, slow and stop.

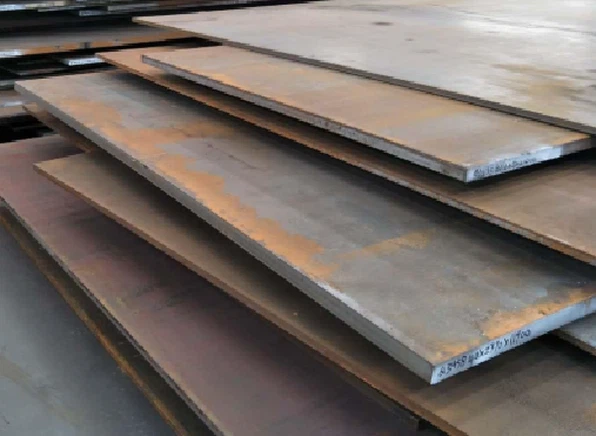

MAIN MACHINE STEEL PLATE THICKNESS

MAIN MACHINE STEEL PLATE THICKNESS

Ordinary Raymond Mill: Thickness 8-10mm

Louder noise Shorter service life Lower machine stability

MR MGW Raymond Mill: Thickness 14-16

30% less noise Longer service life Higher machine stability

MAIN MILL SHAFT AND ROLLER SHAFT

Ordinary Raymond Mill:

Round steel 45, quenched and tempered

Steel plates are made by rolling or other forming processes, and their manufacturing process may not involve plastic deformation and steps to eliminate internal defects. Steel plates usually refer to flat steel rolled by flat rolling mills, and their mechanical properties and structure are not as optimized as forgings.

MR MGW Raymond Mill:

Forged parts, 35CrMo quenched and tempered

Forged parts have denser structure, stronger strength and longer service life. They are made by forging process, have better mechanical properties, and are often used to manufacture parts with high strength and high load requirements.

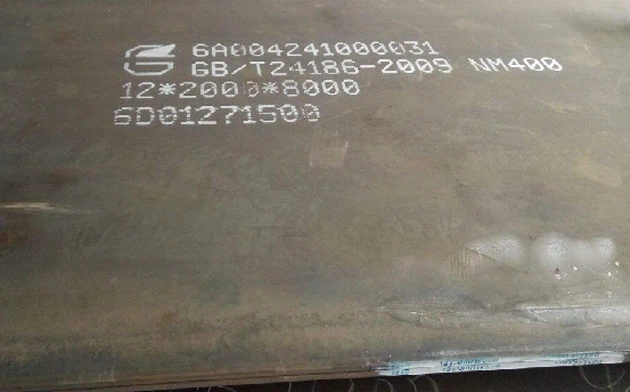

WEAR-RESISTANT MATERIAL

Ordinary Raymond Mill: 65Mn

65Mn has lower wear resistance and weaker impact resistance than NM400.

MR MGW Raymond Mill: NM400 wear-resistant materials

NM400 is more wear-resistant and impact-resistant than 65Mn, and has a service life twice that of ordinary materials.

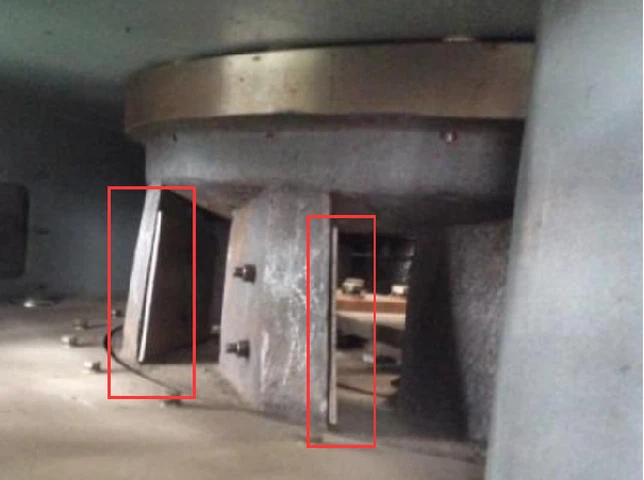

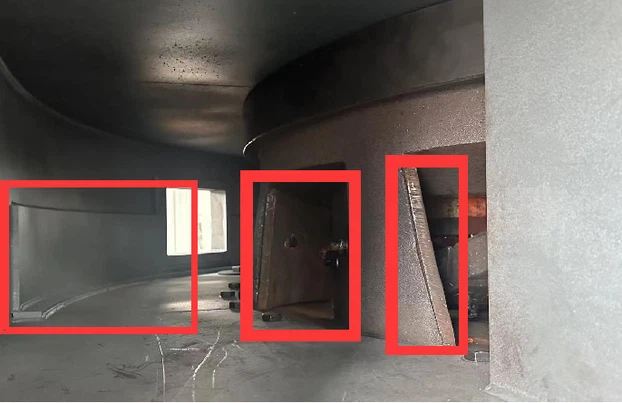

AIR DUCT GUARD PLATE

Ordinary Raymond Mill: Without or with thin air duct guard plate

MR MGW Raymond Mill: With thick air duct guard plate

STEEL PLATE MODEL

Ordinary Raymond Mill:Q235

MR MGW Raymond Mill:Q345

- Q235:ordinary carbon steel

- Chemical composition:

C≤0.20%, Mn≤1.4%, Si≤0.35%,

S≤0.045%, P≤0.045% etc.

- Yield strength lower limit: Q235MPa

- Application: Q235 is often used to make metal structural parts, carburized or cyanide parts with low core strength requirements, tie rods, connecting rods, hooks, couplers, bolts and nuts, sleeves, shafts and weldments.

- Q345: Low alloy structural steel

- Chemical composition:

C≤0.20%, Mn ≤1.7%, Si≤0.55%,

S≤0.045%, P≤0.045%% etc.

- Yield strength lower limit: Q235MPa

- Application: Q345 has good comprehensive mechanical properties, good plasticity and weldability. It is often used as structures, mechanical parts, building structures, etc.

- It is also often used as various structures in cold areas below minus 40 degrees.