Pioneer in Environmentally Friendly Recycling Of Micro Powder Mills

Project Information

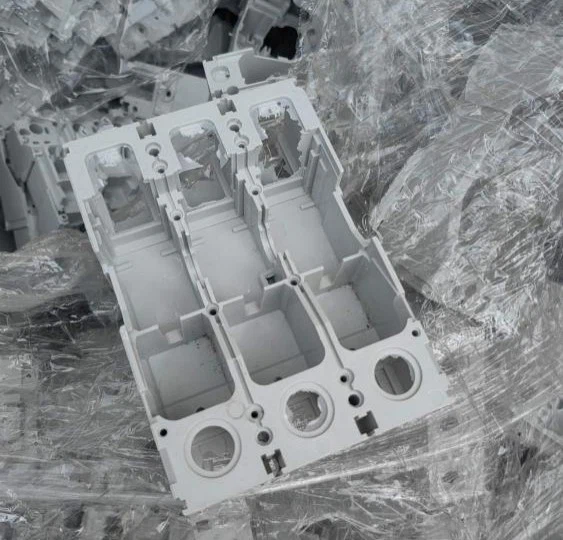

Raw materials: composite materials (50% calcium carbonate, 25% glass fiber, 20% glass-like resin)

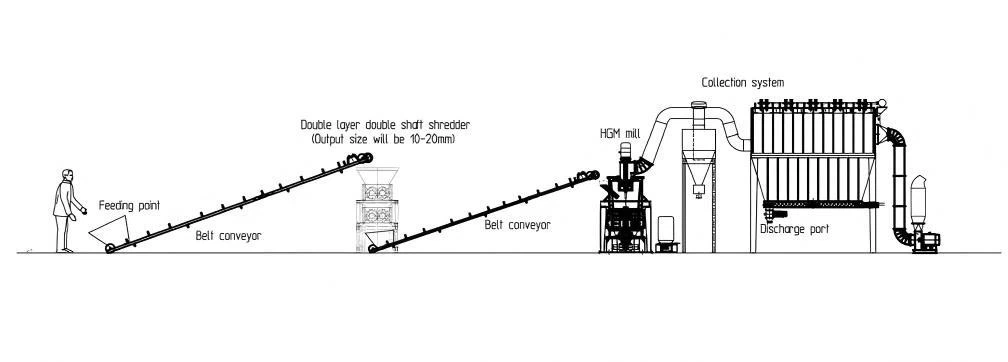

Feed material: less than 10mm (shredded by shredder or crushed by crusher)

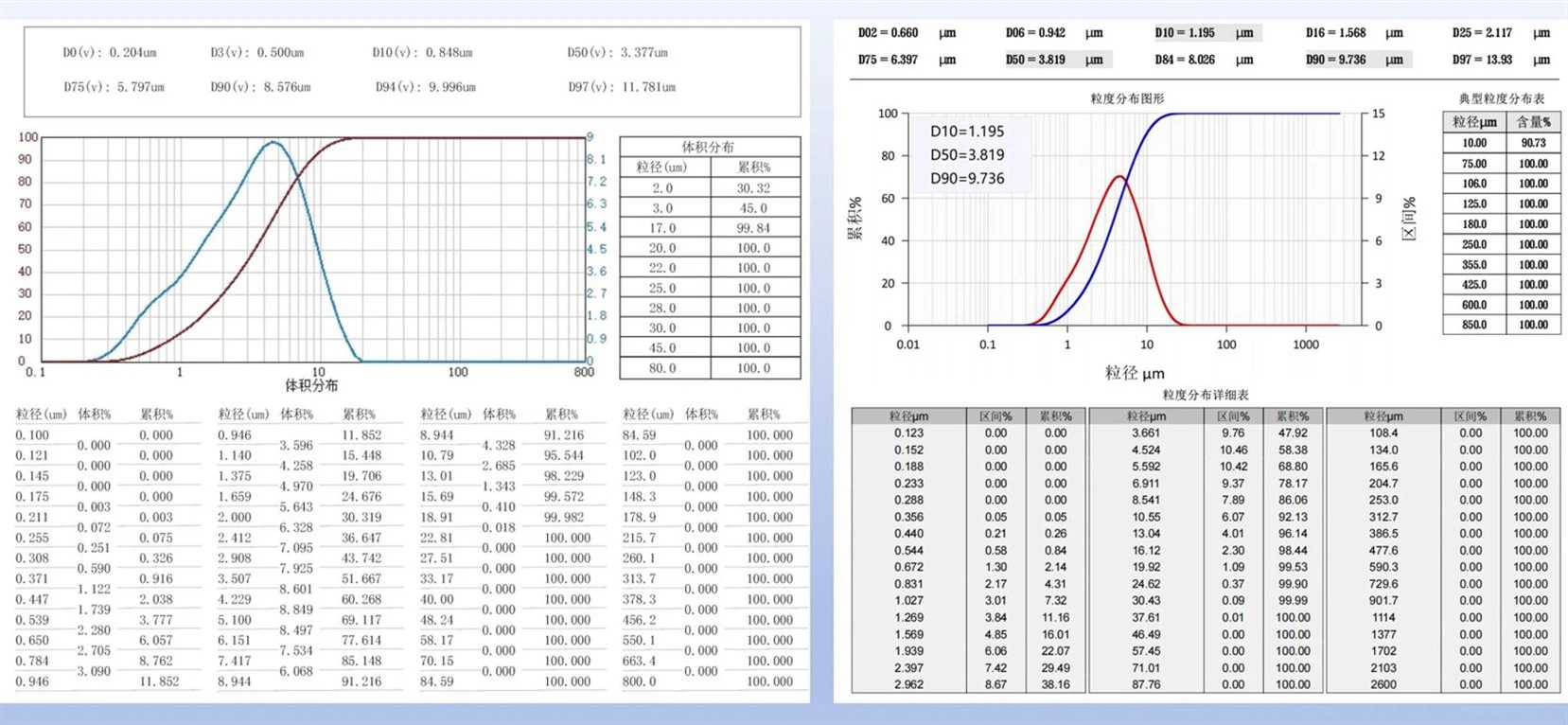

Final product: 1250 mesh/2500 mesh

Passing Rate: 85%, 90%, 95%, 99% (Screening rate varies due to different uses)

Recommended machine model: MSF series fine powder grinding machine

Project Background

Customer A is the head of a multinational company. The raw material that the customer wants to grind is electrical components. It is common because almost every household can use it. It is special because we have been manufacturing mills for more than 20 years, and no customer has ever wanted to grind this material into powder.

The material of these electrical components is a composite material, containing 50% calcium carbonate, 25% glass fiber, and 20% glass-like resin, which has the characteristics of lightweight, high strength, and corrosion resistance.

After our customer A produces this composite material, it will be made into electrical components and sold to companies such as ABB, Siemens, and Schneider, but its strict quality standards lead to the accumulation of defective products. At present, the only way to deal with it on the market is to discard and bury it, but these electrical components are extremely difficult to degrade and are easy to pollute the environment.

Customer A wants to grind these electrical components into powder, and then add them to new materials in a reasonable proportion as recycled materials to manufacture electrical components again. This can not only achieve recycling composite materials waste reuse, but also protect the environment.

After consulting with several manufacturers, customer A was recommended to use a shredder + micro powder mill solution to grind the powder into 1250-2500 mesh. However, due to the particularity of this type of project, this solution has unknowns and uncertainties in terms of technical implementation.

Project Process

When the customer found us, they asked us to quote according to the above plan. Our MR did not quote the customer immediately, but the engineering team carefully analyzed the customer’s project. We asked the customer to send us about 200kg of raw materials, because in our mill factory, there is a ready-made mill production line for the customer to do experiments.

After receiving the customer’s raw materials, we first used a shredder to shred the materials for experiments according to the customer’s requirements. After the experiment, we found that the shredder broke the composite defective products into flocculent debris, and if this flocculent debris enters the MSF series micro powder mill, it will entangle the grinding roller and shaft pin inside the main machine, causing the micro powder mill to malfunction.

MR engineers immediately provided a solution to this problem:

replace the shredder with a hammer crusher. The hammer crusher can completely crush the defective composite materials and avoid the entanglement of flocculent debris. We used the hammer crusher prototype in the factory to conduct experiments and found that the output of the hammer crusher was much larger than 2cm, which was larger than the optimal feed of the micro powder mill.

So we customized the grate bars for the hammer crusher with an opening of 14mm. After the professionally customized hammer crusher, the defective composite materials were in powder form, but the mesh number still did not meet the customer’s requirements. At this time, the micro powder mill can finely grind the material and finally produce a high-mesh powder that meets the customer’s standards.

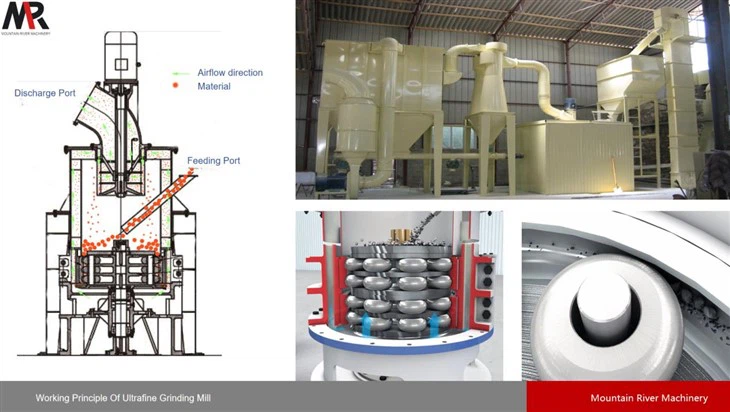

How does the MSF Micro Powder Mill Grind Raw Materials into Powder?

The material falls from the scattering disc into the gap between the grinding roller and the grinding ring. At this point, the motor drives the main shaft to rotate via the V-belt, initiating the operation of the grinding roller assembly.

The main motor drives the grinding disc to rotate through the V-belt, and the powder forms a “material layer crushing” effect under the action of centrifugal force. Then they enter the grading powder selection machine for screening, and the grading accuracy can reach D100<5μm (above 2500 mesh).

Therefore, the finished powder screened out will be collected by the pulse dust collector to form the finished powder, meeting the customer’s psychological expectations.

Inspection and Testing

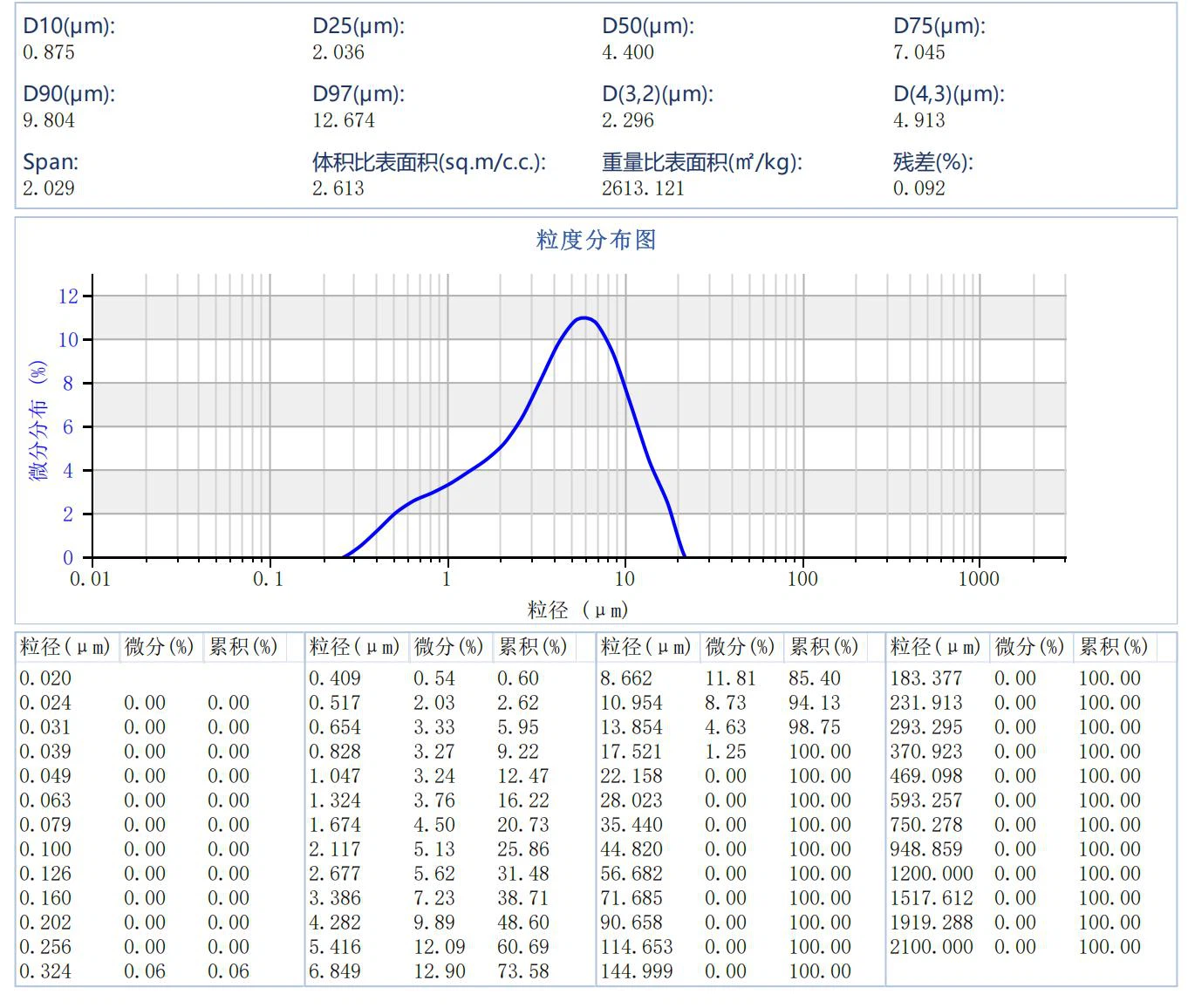

The customer was also very strict in the inspection of the finished powder. They sent the sample powder after grinding by the micro powder grinding mill to three domestic and foreign authoritative institutions for testing.

When the test reports showed that the particle size index not only met the standard but also far exceeded the customer’s expectations, the customer was very surprised. Our MR not only solved the problem that they had been troubled by, but also persistently helped the customer to do various experiments until the final requirements were met.

Under strict quality verification and professional services that exceeded expectations, our MR and the customer finally reached a pleasant transaction.

We expect that the MSF ultrafine powder milling equipment, a mining equipment specialized in grinding ultrafine powders, will not only create monetary value for customers, but also contribute to the sustainable circulation of resources and environmental protection!

We expect that the MSF ultrafine powder milling equipment, a mining equipment specialized in grinding ultrafine powders, will not only create monetary value for customers, but also contribute to the sustainable circulation of resources and environmental protection!