Raymond Mill Grinder

MTW raymond mill is suitable for processing various non-flammable and non-explosive mineral materials with Moh’s hardness lower than 9. It is widely used in the fields of metallurgy, construction, chemical industry and so on.

Introduction of Raymond Mill Grinder

MGW series raymond mill grinder is mainly used to grinding material of metallurgy, building materials, chemical industry, mining and other industries. The raymond grinding mill is a good option to grind non-metallic material to powder 200 mesh to 325 mesh.

Technical Advantages

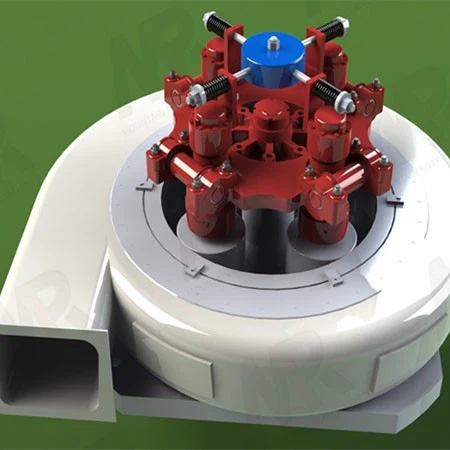

(1) MGW series raymond mill grinder adopts integral bevel gear transmission technology, which makes the structure of the transmission system more compact, the installation and adjustment are more convenient and fast, and the service life of important components is greatly extended.

(2) Curved surface shovel with exchangeable blade

The shovel used in the traditional grinding mill is an integral design. Once the blade is worn out, the shovel needs to be replaced as a whole, which is time-consuming and laborious. Moreover, the shovel has a flat design, and the materials scooped up will accumulate in the limited area of the grinding part, resulting in grinding Uneven wear in the middle of the rollers and grinding rings, which ultimately leads to increased production costs. The MGW series grinding mill adopts a split-type curved blade. When replacing it, only the blade part needs to be replaced. At the same time, the blade is made of high wear-resistant alloy material, which greatly prolongs the service life and improves the utilization rate of materials and the working efficiency of the machine. In addition, the curved shovel can guide the material to the vertical surface, so that the upper, middle and lower parts of the grinding roller and grinding ring can be ground, so that the wear is uniform, and at the same time, the effective working area is increased, and the output of the machine is improved.

(3) No resistance inlet volute (small observation door without vortex)

The inner surface of the observation door of the MGW series mill is on the same curved surface as the inner surface of the air inlet volute, which can effectively avoid the occurrence of eddy current effect and reduce the energy consumption of the system.

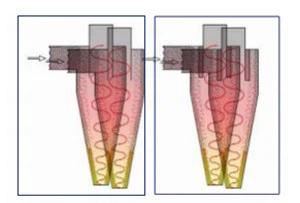

(4) Isolated cyclone collector

The MGW series pulverizer adopts the isolated cyclone powder collector, and the isolation structure is adopted between the inner cylinder and the mixed air powder flow, which can effectively improve the powder selection efficiency and powder selection accuracy.

Traditional cyclone collector Isolated cyclone collector

Technical Parameters

Question from MR customer: It is our first time of buying and using the crushers and grinding mills, what after sales service will you provide us? Can MR send us an engineer for installation?

Answer from MR Factory: Thank you for purchasing from us! Your purchase is the very beginning of our service! In case you have no experience , we will take the following measures in a targeted manner:

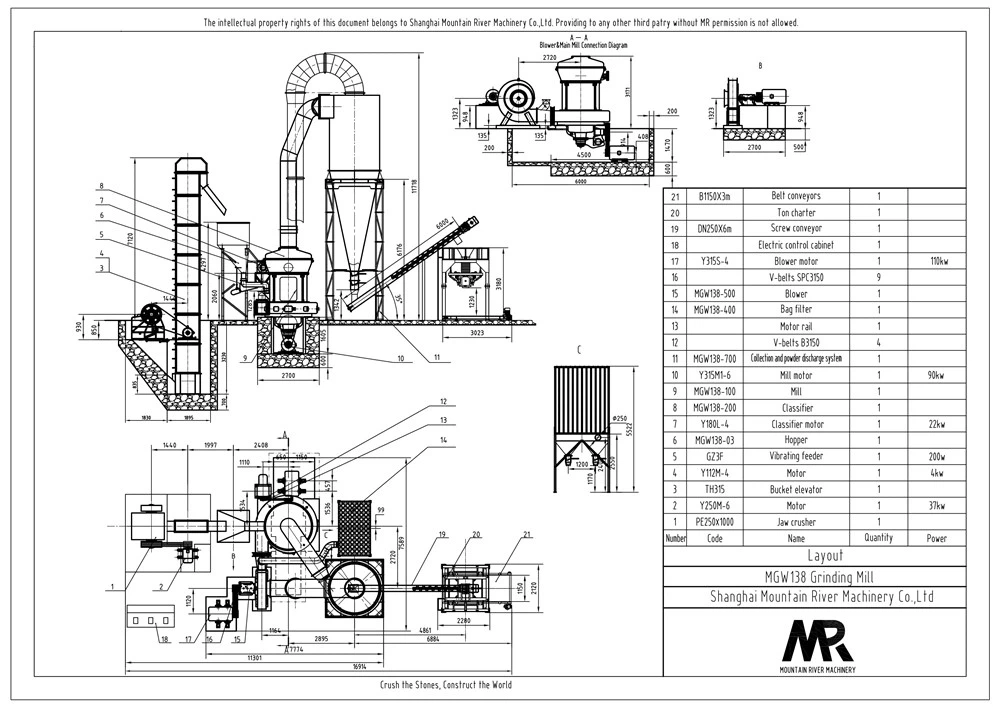

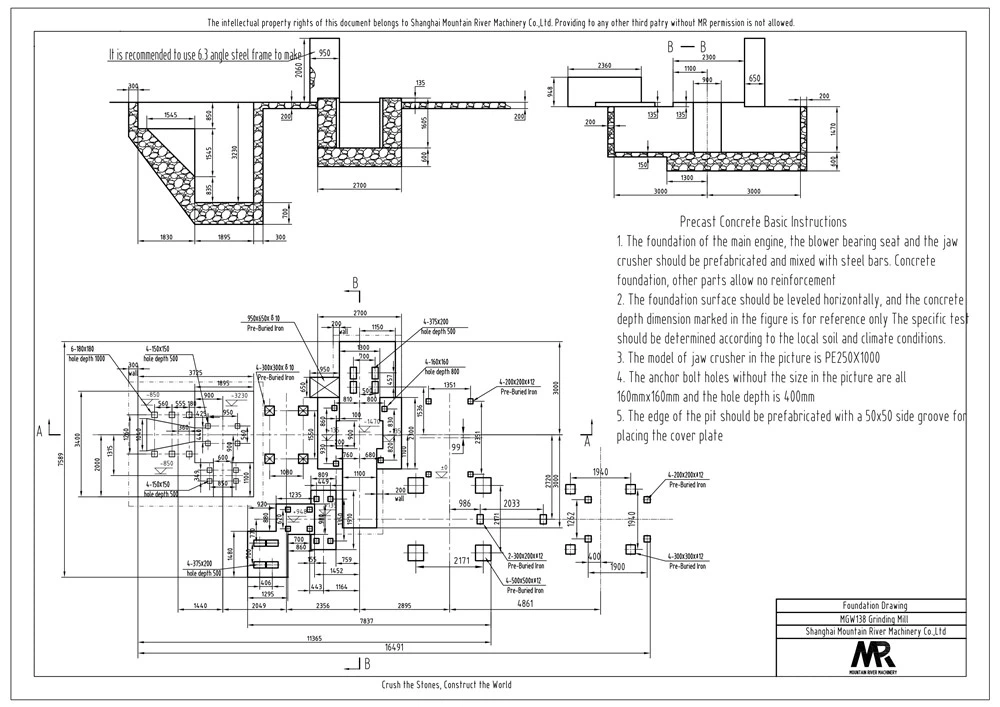

(1) Supply of Fundation Drawing

We will send you foundation plans, installation instructions, complete electrical diagram of the plant after 5 (five) working daysafter the down payment is received. Here we give you an example of our drawings:

(2) List of Equipment &Tools Necessary for Installation

Our professional engineer will prepare a list of equipment & tools necessary for installation. For example, the quantity need of cement, the model of crane, quantity of labors needed, area of workshop needed…

(3) Sending MR Professional Engineer to Your Site for Installation

Our customers will be responsible for civil engineering, accessory materials, crane, light and power supply, and other necessary things. MR technician is one person and he will guide the installation and train local workers to operate the machine. Our customers shall pay the salary for our MR technician, as well as round-trip tickets, lodging, food, personal insurance, communication cost, etc. Meanwhile our customers must ensure the safety and freedom of the technician during the installation.

Key Spare Parts