Brazil: Alumina Raymond Mill Production Line

South America is a core market that MR is focusing on developing. We have established long-term, stable relationships with clients in countries such as Brazil, Argentina, Paraguay, and Uruguay. We also have a comprehensive local team in South America to ensure seamless customer support.

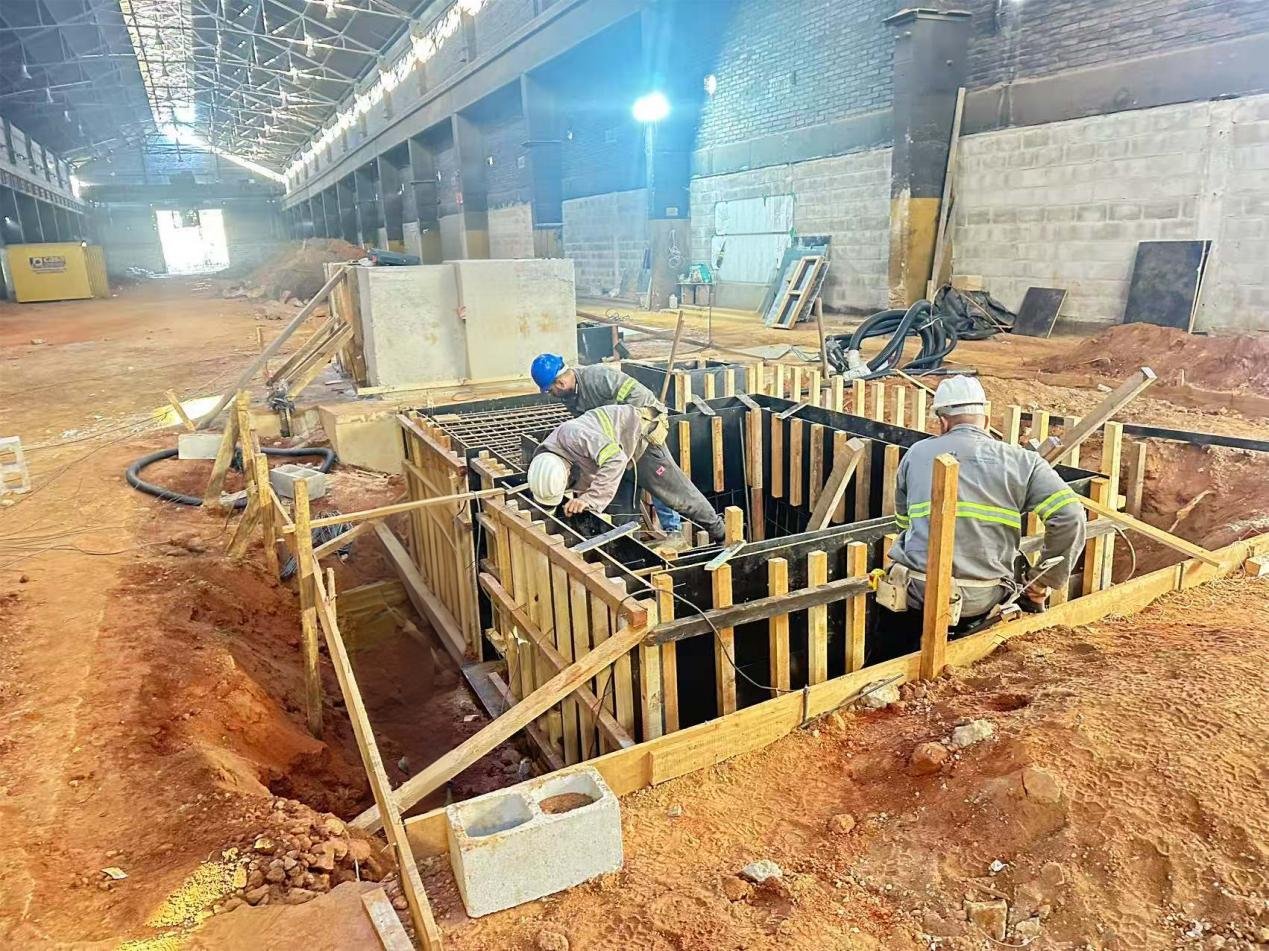

Recently, a high-performance Raymond mill purchased by a Brazilian client has been officially delivered to the region. This mill will be used in a major mining project in Brazil. MR has assigned experienced local technicians to oversee the installation and commissioning process to ensure efficient operation.

Details of this Raymond mill production line are as follows:

Raw material: Alumina

Feed size: 5mm or less

Discharge size: 325 mesh

Passing rate: 99%

What is Alumina?

Alumina (Al₂O₃) is a highly hard, white, powdered inorganic compound with properties such as high-temperature resistance, corrosion resistance, and high electrical insulation. Due to its stable chemical properties and wide range of applications, alumina is typically ground into a fine powder using a Raymond mill. This finely ground alumina powder is widely used in various industries:

In the metallurgical industry, it serves as a core raw material for the electrolytic production of aluminum metal.

In the ceramics industry, it serves as a reinforcement for high-performance ceramics (such as structural ceramics and electronic ceramics).

In the chemical industry, it serves as a catalyst carrier or adsorbent.

In the electronics industry, it is used in the manufacture of integrated circuit substrates and insulation materials.

Finely processed alumina powder using a Raymond mill can better meet the stringent particle size, purity, and performance requirements of various industries, further expanding its industrial value.

MGW Raymond Mill Advantages

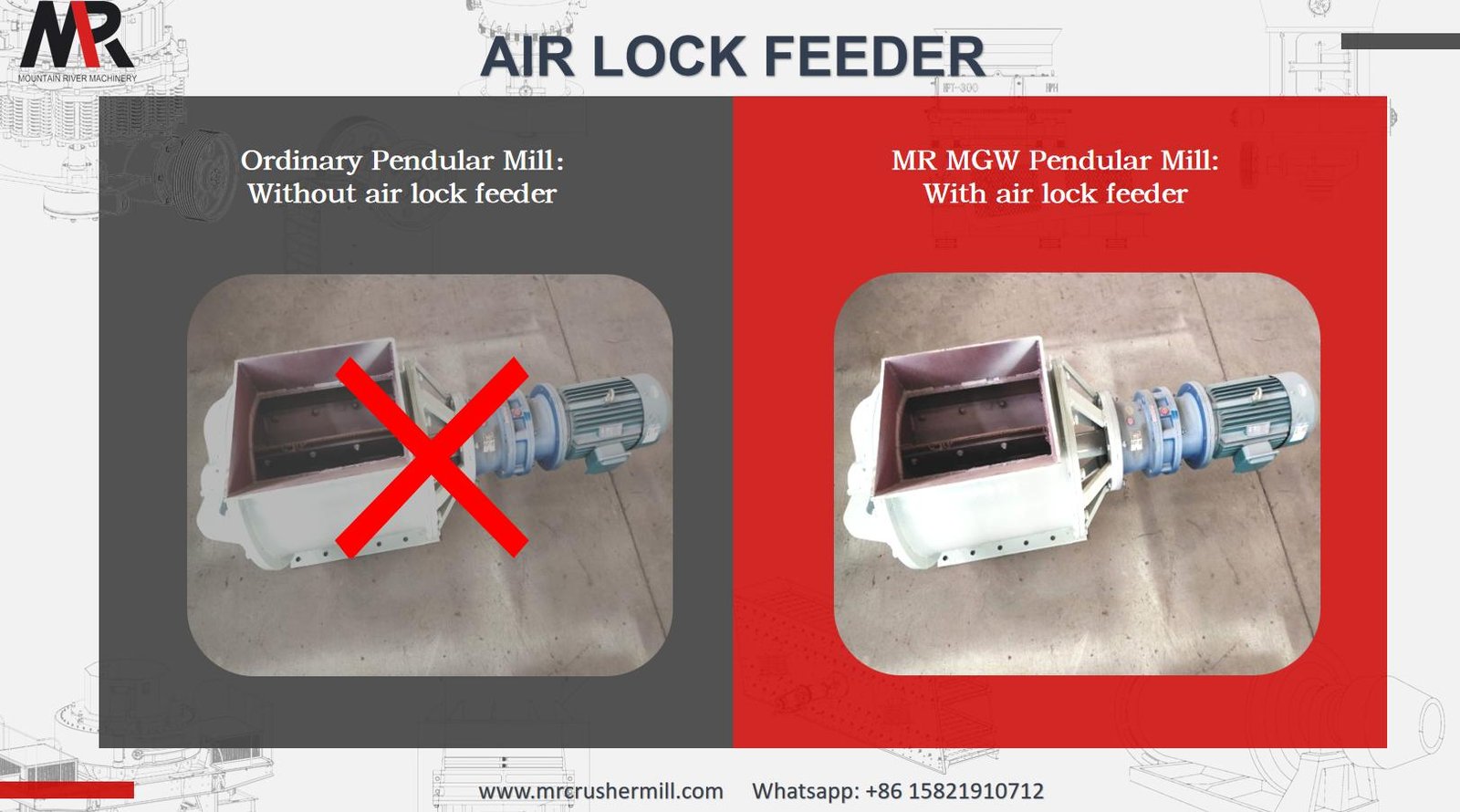

1.It utilizes an air-locking feeder to prevent dust from leaking and ensure uniform feeding.

2. The cage type powder classifier is used to greatly improve the powder selection accuracy and fineness stability. Under the same fineness, the output of the grinding mill is increased by 5-10% compared with the blade type powder classifier.

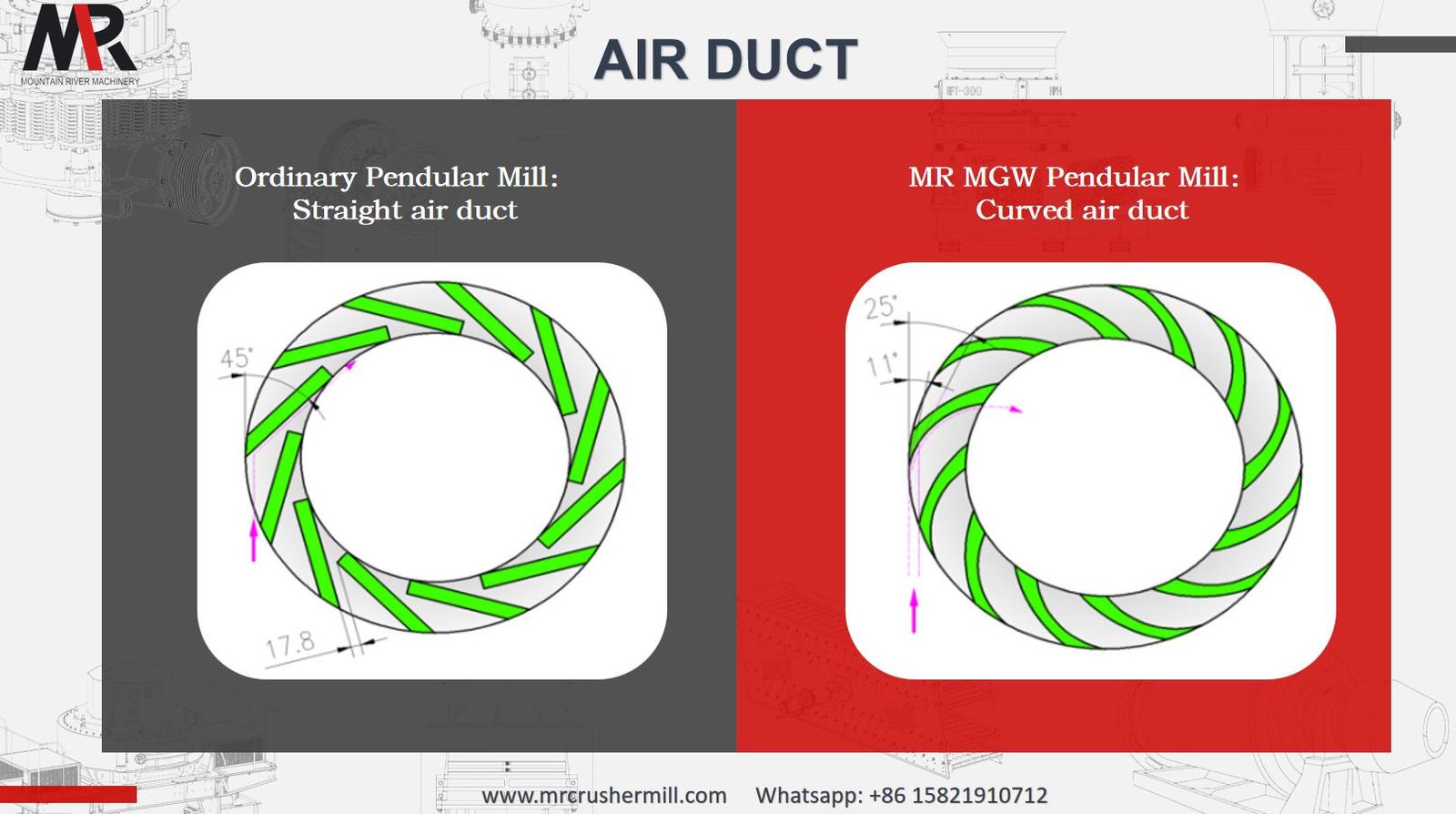

3.The air duct is a curved type, the tangential air flow inlet is smooth and the resistance is small. The internal outlet direction is conducive to the dispersion of materials and is not prone to blockage.

MGW Raymond Mill Installation Precautions

- Install the main machine first, then calibrate the transmission system. Ensure the main machine pulley is aligned and parallel to the main machine motor pulley. Ensure the belt preload is sufficient to prevent slipping and burning.

- During installation, ensure the classifier pulley is aligned and parallel to the classifier motor pulley. Ensure the belt preload is sufficient to prevent slipping and burning.

- During on-site piping installation, gaskets should be installed at the joints between components to prevent air leaks that could affect production.

- If the two components do not fit correctly due to foundation or manufacturing errors, local adjustments should be made before reconnecting.