Brazil: Graphite Ball Mill Customer Faces Installation Challenges MR Efficiently Resolves Slurry Leakage Issue

Implemented Project

In the mining equipment sector, quality after-sales service often determines customer trust and long-term collaboration. Recently, MR partnered with a new customer to implement a graphite ore ball mill production line in Brazil.

However, an accident occurred during the ball mill installation, resulting in slurry leakage. With professional technical support and efficient on-site services, MR successfully helped the customer solve the key problems in the graphite ball mill production line and won high praise from the customer.

Raw Material: Graphite ore

Feed Size: 0-10mm

Discharge Size: 150-200 mesh

Production Capacity: 2-3 tph

Why does the Graphite Ore Ball Mill Leak Slurry?

Due to the previous experience of ball mill installation, the Brazil customer declined the request of MR engineers to accompany them in the installation of the graphite ball mill project and said that their team could successfully complete the project.

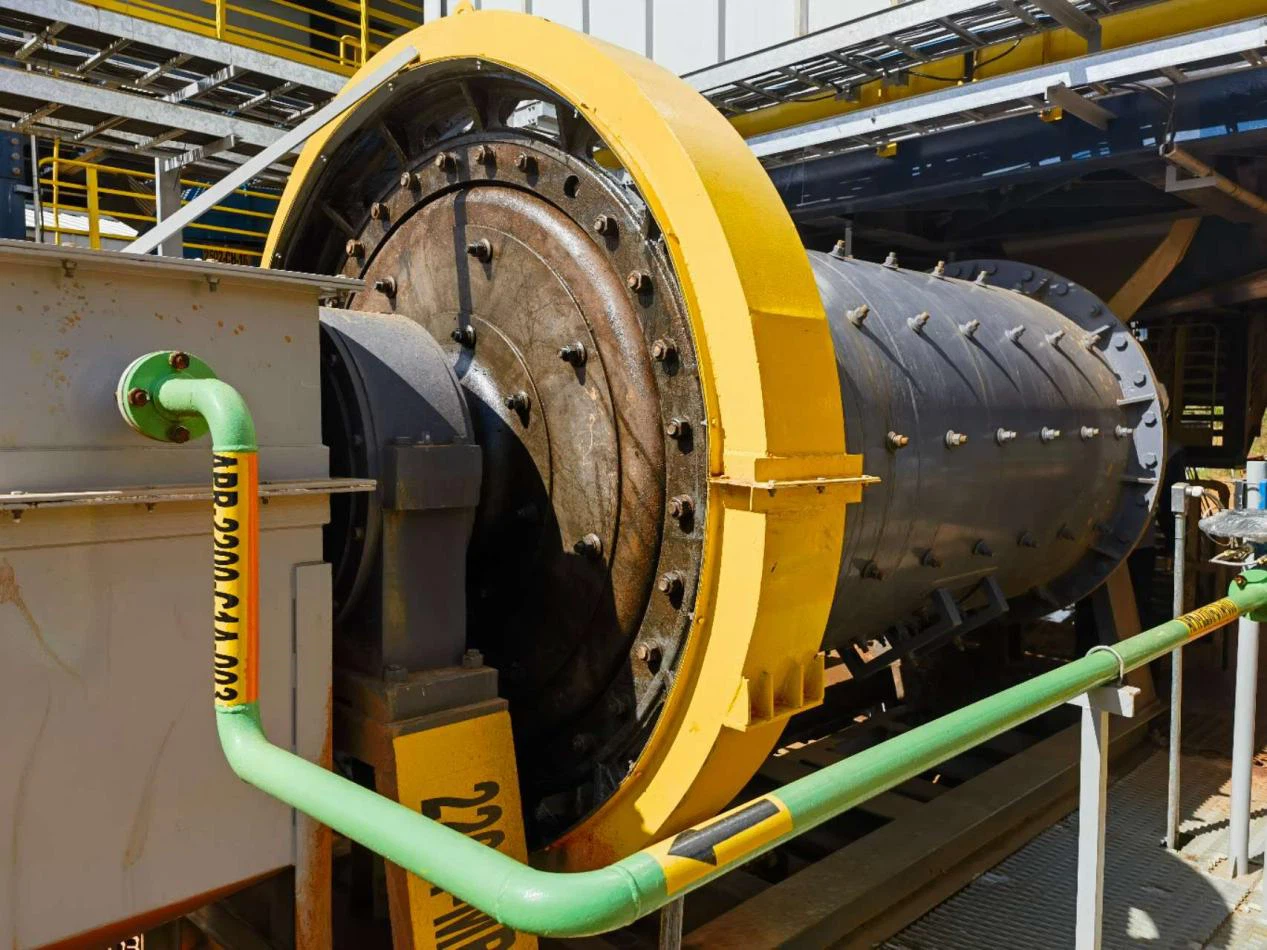

The initial operation of the ball mill seemed to be smooth, but then during the machine debugging, it was found that the ball mill had slurry spill from the feeding chute, which affected the production progress.

In desperation, the customer had to seek help from MR’s engineering team. After learning of this situation, MR team immediately conducted an inspection and concluded that the cause of the leakage was due to two key mistakes:

1. The feed screw was installed upside down, and the customer may have mistaken the discharge screw for the feed screw.

2. The customer cut a sealing rubber at the feed port, causing slurry leakage.

After accurately diagnosing the problem, MR after-sales team acted quickly and arrived at the site with a new seal ring for slurry spill fix. After a leakage troubleshooting, the engineer not only replaced the seal, but also found that the angle deviation of the feed pipe affected the sealing effect.

MR immediately adjusted the pipe to be completely horizontal, completely solving the leakage problem and ensuring stable operation of the equipment.

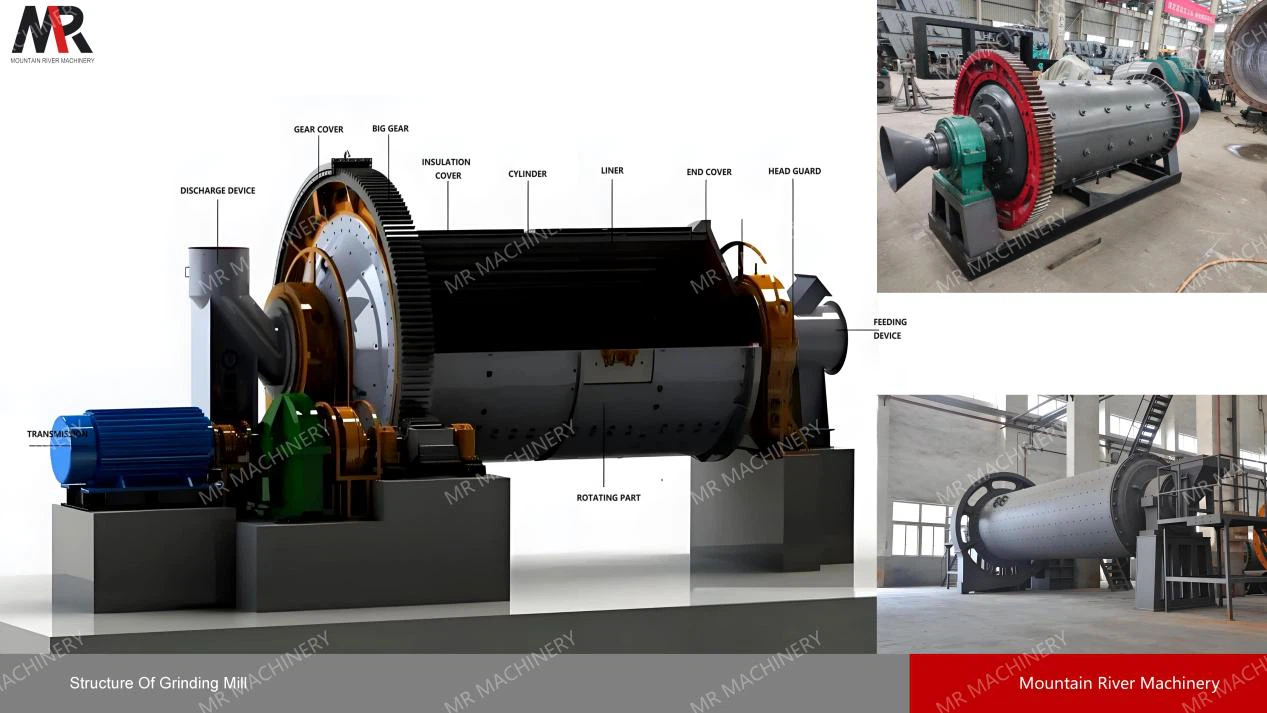

Ball Mill Main Structure

According to the above ball mill repair plan, let’s review the ball mill main structure to prevent errors during the installation process.

The graphite ore ball mill is mainly composed of a feeding system: a screw feeder, a sealing rubber ring, a rotating cylinder (lined with wear-resistant steel plates), a transmission device (IP65 protection motor/reducer) and a discharging system. In the case, MR focused on optimizing the feeding structure to ensure the safe production of the graphite ball mill.

MR Motor Equipment: IP65 Protection Level Guarantee

The graphite produced by the customer is conductive, and the protection level (IP65) of the motor and reducer is extremely high. The equipment provided by MR fully meets the standards, has excellent dust and water resistance, and can operate stably even in harsh working conditions.

Ball mill in Brazil , the customer was very satisfied with the product quality and service, and clearly expressed the hope to continue to cooperate with MR in future new projects, giving it a very high evaluation.

Technical Parameters

| Model | Power (KW) |

Thickness (mm) |

Ball load (t) |

Weight (t) |

Model | Power (KW) |

Thickness (mm) |

Ball load (t) |

Weight (t) |

| Φ900*1800 | 18.5 | 10 | 1.5 | 4.6 | Φ2200*6500 | 380 | 22 | 35 | 52.8 |

| Φ900*3000 | 22 | 10 | 2.7 | 5.6 | Φ2200*7000 | 380 | 22 | 35 | 54 |

| Φ1200*2400 | 30 | 12 | 3 | 12 | Φ2200*7500 | 380 | 22 | 35 | 56 |

| Φ1200*3000 | 37 | 12 | 3.5 | 12.8 | Φ2400*3000 | 245 | 24 | 27 | 60 |

| Φ1200*4500 | 55 | 12 | 5 | 13.8 | Φ2400*4500 | 320 | 24 | 30 | 65 |

| Φ1500*3000 | 75 | 16 | 7.5 | 15.6 | Φ2400*7000 | 475 | 24 | 54 | 71 |

| Φ1500*4500 | 110 | 16 | 7.5 | 21 | Φ2700*3600 | 400 | 25 | 39 | 83 |

| Φ1500*5700 | 130 | 16 | 12 | 25 | Φ2700*4000 | 400 | 25 | 40 | 85 |

| Φ1830*3000 | 130 | 18 | 11 | 28 | Φ2700*4500 | 430 | 25 | 48 | 89 |

| Φ1830*4500 | 155 | 18 | 15 | 32 | Φ2700*6000 | 630 | 25 | 53 | 93 |

| Φ1830*6400 | 210 | 18 | 21 | 34 | Φ3200*3600 | 560 | 30 | 52 | 120 |

| Φ1830*7000 | 245 | 18 | 23 | 36 | Φ3200*4500 | 800 | 30 | 65 | 125 |

| Φ2100*3000 | 210 | 20 | 19 | 43 | Φ3200*5400 | 800 | 30 | 81.6 | 130 |

| Φ2100*4500 | 245 | 20 | 24 | 46 | Φ3000*11000 | 1250 | 30 | 95-100 | 155 |

| Φ2100*7000 | 280 | 20 | 26 | 50 | Φ3600*4000 | 800 | 35 | 75 | 185 |

This case once again proves that MR not only provides high-performance mining equipment, but also we can solve problems quickly because we have a branch and a spare parts warehouse in Brazil. We can win market reputation with quick response and professional technical support, and help global customers achieve efficient production. If you are interested in mining equipment, please call +86 135 2417 5811. You will be a VIP customer of MR and enjoy a full range of services.