Ultra-fine Pulverizer

Ultra-fine powder grinding mill is a new type of grinding equipment specially used to grind non-metallic minerals to 325-2500 mesh ultra-fine powder.

Introduction of Ultra-fine Pulverizer

Ultra-fine pulverizer is a new type of grinding mill specially used to grind non-metallic minerals to 325-3000 mesh ultra-fine powder. By absorbing advantages from 12 kinds of different mills, our engineers finally developed this high-efficiency and low-cost ultra-fine pulverizer by investigation and trial.

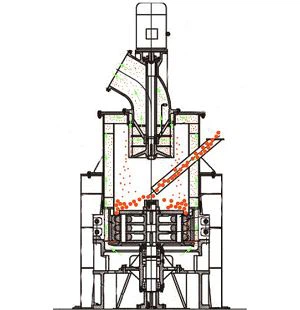

Working Principle

The raw material will be fed into the hammer crusher to be crushed. The bucket elevator will load the crushed material below 20mm and then feed it into the main mill through a hopper and a belt feeder.

The motor of the main mill drives the center shaft and disc rotor to rotate through the reducer. The roller pins on the edge of the grinding disc drive the grinding rollers to roll in the mill roller path. The material will fall on the distribution plate above the disc rotor, moving sideward under the action of centrifugal force, and then falling into the mill roller path for being crushed and grinded between the ring and rollers. After being processed through roller paths, the material will become ultra-fine powder. The high-pressure blower will inhale outside air into the mill body, then taking the grinded material into the powder classifier.

The rotating impellers in the classifier will drive the coarse particles to fall back for repeated grinding,with the qualified fine powder forced into the cyclone powder collector along with the air flow and discharged from the lower discharge valve as finished products, while the air flow with small amount of fne dust will be discharged out of the mill via the blower and muffler after being purified by the impulse dust collector.

Key Spare Parts

| No. | Picture | Name |

| 1 |  |

Rollers |

| 2 |  |

Ring |

| 3 |  |

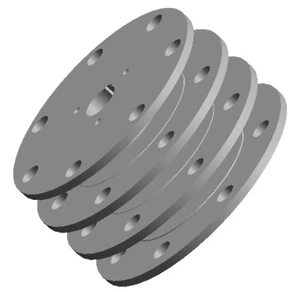

Turntable |

| 4 |  |

Pins |

Technical Parameters

Content | Model | ||||

MSF600 | MSF800 | MSF1000 | MSF1250 | MSF1680 | |

Roller qty. (pieces) | 12 | 21 | 28 | 32 | 44 |

Diameter of ring(mm) | φ600 | φ800 | φ 1000 | φ1250 | φ1680 |

Main shaft speed (rpm) | 250-280 | 230-240 | 180-200 | 135-155 | 120-130 |

Max.feeding size (mm) | 20 | 20 | 20 | 20 | 25 |

Final size(mesh) | 325-2500 | 325-2500 | 325-2500 | 325-2000 | 325-2000 |

Capacity (tph) | 0.2-3 | 0.5-4.5 | 1-8.5 | 2.5-14 | 5-25 |

Dimension(m) | 11.5*3.5*5.2 | 13*3*5.8 | 18*4.6*8.6 | 14*9*10.25 | 16*5*11 |

Main mill (kw) | 45 | 75 | 132 | 200 | 315 |

Classifier(kw) | 15 | 18.5 | 30 | 75 | 132 |

Blower(kw) | 37 | 45 | 75 | 132 | 200-220 |

Hammer crusher Motor(kw) | PC300×400 PC400×600 | PC400×600 | PC600×800 | PC600×800 | PC600×800 |

11/18.5 | 18.5 | 45 | 45 | 45 | |

Bucket elevator Motor(kw) | TH200×8.2m TH200×6.04m | TH200×9.79m | TH300×11.05m | TH300×13.55m | TH300*16.31m |

3 | 3 | 4 | 5.5 | 7.5 | |

Belt feeder Motor(kw) | 300×60 ×1000mm | 300×60 ×1800mm | 300×60 ×1800mm | 400×80 ×2000mm | 400×80 ×2800mm |

1.1 | 1.5 | 1.5 | 1.5 | 2.2 | |

Pulse dust collector | DMC96 | DMC120 | LDMC35-8 | LDMC64-9 | LDMC64-9 (2sets) |

DMC160 | |||||

Discharge screw conveyor Motor(kw) | / | LS219-4.5 | LS245-6.2 | LS315-10.34 | LS315-10.34 (2sets) |

LS219-3 | |||||

/ | 3/3 | 4 | 7.5 | 7.5*2 | |

Air compressor Motor (kw) | KSH150D | KSH240D | LGY5-8 | LG6.2/8 | LG10/8 |

11 | 15 | 30 | 37 | 55 | |

Packaging and Loading