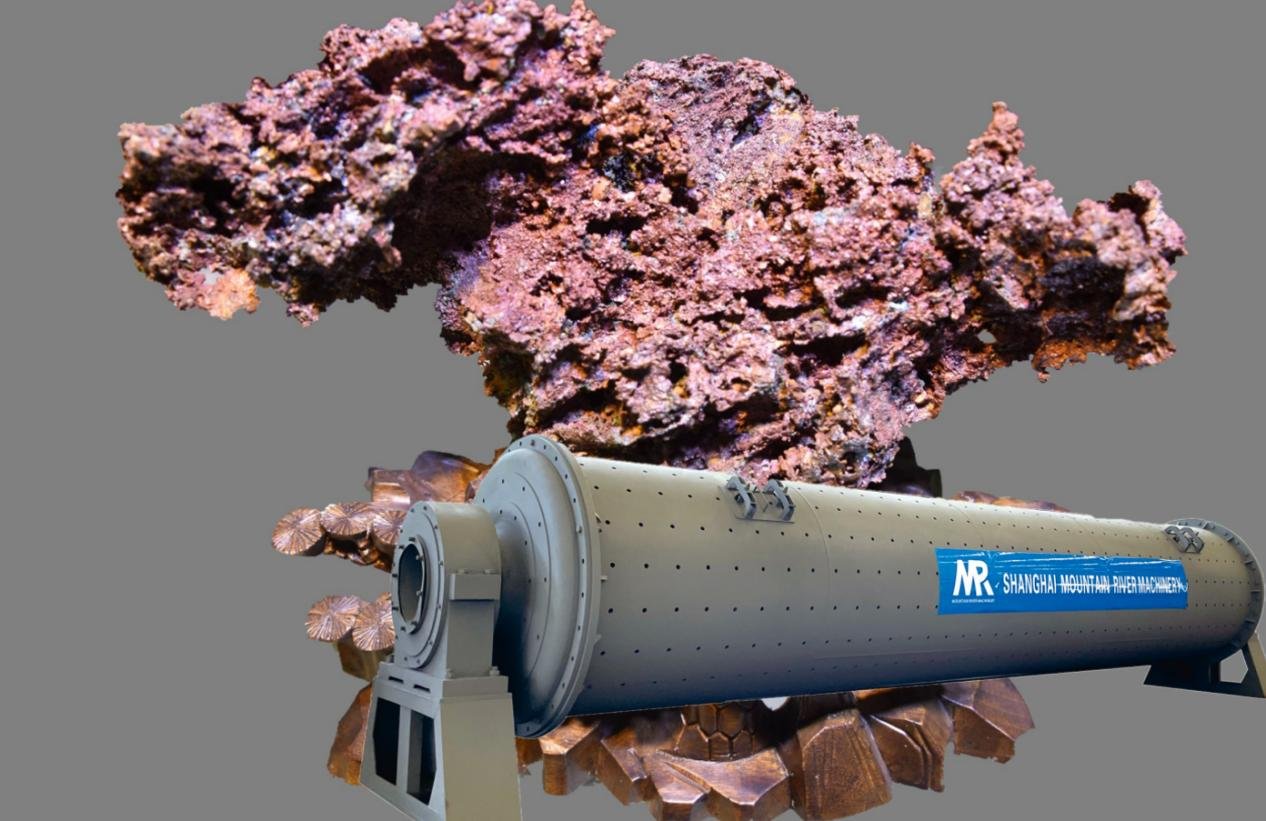

Copper Ball Mill, Latin American Mining Project

MR recently completed the packing and shipping of a batch of high-performance ball mills. This equipment has departed for a major mining project in Latin America, where it will be used for copper ore grinding. Throughout the entire ordering process, we provided comprehensive, high-end services: from initial technical consultation and equipment selection to transport planning and cross-border logistics coordination.

Project Information

Raw Material: Copper Ore

Feed: 0-12 mm

Output: 200 mesh, 80% pass rate

Production: 254 t/h

The Market Value of Copper Ore

Copper is a key industrial metal, and its demand and price are closely linked to global economic growth and technological trends. Recently, copper demand has experienced strong growth, driven by the global energy transition, particularly the rapid expansion of electric vehicles, charging infrastructure, and renewable energy.

Market data for the second half of 2025 shows that copper prices remain at historically high levels. This market context not only reflects the strength of current demand but also underscores the strategic importance of having efficient and reliable mineral processing equipment. Implementing high-performance ball mills allows mining companies to increase processing capacity and improve ore recovery rates, thereby maximizing the return on investment during periods of favorable prices.

Advantages of the MR Ball Mill

The MR ball mill cylinder is manufactured from high-performance, wear-resistant steel plates with a thickness optimized through computer simulation. This ensures superior mechanical strength and load-bearing capacity, enabling it to withstand the continuous impact and wear of hard copper ore. The service life of key wear parts is extended by approximately 40% compared to standard products on the market.

Compared to conventional ball mills, MR equipment offers an average wear part life that is 40% to 60% longer, significantly reducing downtime for replacements and directly lowering long-term operating and maintenance costs. Furthermore, we have a local MR after-sales technical engineering team that can promptly address any issues. For equipment-specific problems, the MR in-house engineering team can resolve them more quickly and efficiently.

Why choose MR service?

It’s worth noting that our sales engineers and service technicians are fluent in Portuguese, enabling precise technical communication in the native language of our Brazilian clients. This not only ensures smooth project execution but also provides clients with greater peace of mind when acquiring large-scale equipment. This local and professional service is one of MR’s key advantages in the South American market.

If your project also requires crushing or grinding equipment, please contact us. MR will become your most reliable partner on your journey to maximizing the value of your mineral resources.