Ball Mill In China

The ball mill, also known as a grinding mill, is a crucial piece of machinery used to grind materials for various applications.

Introduction

The ball mill, also known as a grinding mill, is a crucial piece of machinery used to grind materials for various applications. It is widely used in industries such as cement, silicate products, new building materials, refractory materials, and glass ceramics.

Working Principle

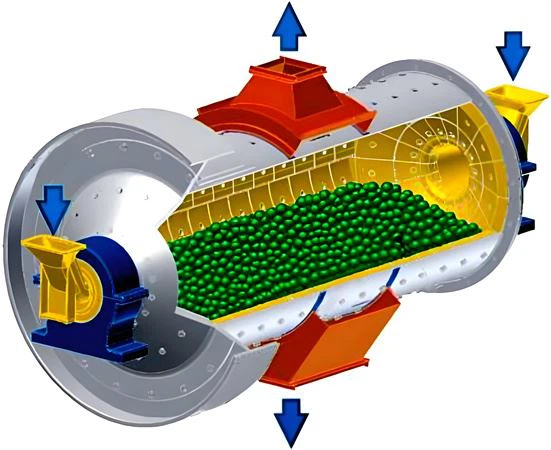

Ball mill consists of several components, including the main cylinder, motor, reducer, bearings, feeding and discharging devices, and grinding media. Their perfect combination enables the ball mill machine to achieve efficient grinding of materials. The working principle of the ball mill is to rotate the cylinder by driving the motor through the reducer and bearings. While rotating, the grinding media and slurry enter the cylinder, forming friction and pressure to achieve grinding powder. The grinding media can be steel balls or ceramic balls, which adjusts its position and shape in interaction with the cylinder, accelerating the grinding process and improving the grinding efficiency of the material. By controlling the speed and position of the feeding and discharging devices, the particle size of the material can be adjusted and the mixing process can be controlled.

Technical Advantages

1. Efficient And Reliable Grinding:

In the early stage of material crushing, the ball mill can effectively complete the coarse crushing of the material, and preliminarily crush the material into a particle size suitable for the next step of processing, thereby improving the production and processing efficiency.

2. Easy To Operate:

The ball mill does not require the use of complex mechanical structures and systems, is easy to operate, and is easy to maintain and maintain. As long as you master some simple operating skills, you can smoothly carry out the production and processing of materials.

3.Good Processing Effect.

The ball mill uses steel ball friction and other methods to quickly grind materials and achieve powder grinding of different particle sizes and qualities, with certain selectivity and sorting effects.

4. Environmentally Friendly

The ball mill uses high-efficiency energy-saving technology and advanced dust collection systems to reduce dust emissions and energy consumption, and reduce pollution and negative impacts on the environment.

Technical Parameters

Model | Power (kW) | Thickness (mm) | Ball load (t) | Weight (t) |

φ900*1800 | 18.5 | 10 | 1.5 | 4.6 |

φ900*3000 | 22 | 10 | 2.7 | 5.6 |

φ1200*2400 | 30 | 12 | 3 | 12 |

φ1200*3000 | 37 | 12 | 3.5 | 12.8 |

φ1200*4500 | 55 | 12 | 5 | 13.8 |

φ1500*3000 | 75 | 16 | 7.5 | 15.6 |

φ1500*4500 | 110 | 16 | 7.5 | 21 |

φ1500*5700 | 130 | 16 | 12 | 25 |

φ1830*3000 | 130 | 18 | 11 | 28 |

φ1830*4500 | 155 | 18 | 15 | 32 |

φ1830*6400 | 210 | 18 | 21 | 34 |

φ1830*7000 | 245 | 18 | 23 | 36 |

φ2100*3000 | 210 | 20 | 19 | 43 |

φ2100*4500 | 245 | 20 | 24 | 46 |

φ2100*7000 | 280 | 20 | 26 | 50 |

φ2200*6500 | 380 | 22 | 35 | 52.8 |

φ2200*7000 | 380 | 22 | 35 | 54 |

φ2200*7500 | 380 | 22 | 35 | 56 |

φ2400*3000 | 245 | 24 | 27 | 60 |

φ2400*4500 | 320 | 24 | 30 | 65 |

φ2400*7000 | 475 | 24 | 54 | 71 |

φ2700*3600 | 400 | 25 | 39 | 83 |

φ2700*4000 | 400 | 25 | 40 | 85 |

φ2700*4500 | 430 | 25 | 48 | 89 |

φ2700*6000 | 630 | 25 | 53 | 93 |

φ3200*3600 | 560 | 30 | 52 | 120 |

φ3200*4500 | 800 | 30 | 65 | 125 |

φ3200*5400 | 800 | 30 | 81.6 | 130 |

φ3000*11000 | 1250 | 30 | 95~100 | 155 |

φ3600*4000 | 800 | 35 | 75 | 185 |