Raymond Mill for Barite Grinding

Recently, we MR successfully installed a barite Raymond grinder plant in South America. The smooth implementation of this fine powder production project creates higher value for customers, and also proves once again that customers are right to choose our MR grinding equipment!

Project Information

Recently, we MR successfully installed a Raymond Mill for barite grinding plant in South America. The smooth implementation of this fine powder production project creates higher value for customers, and also proves once again that customers are right to choose our MR grinding equipment.

The actual barite powder making plant details are as follows:

Raw Material: Barite

Production Capacity: 13.5 tph

Size Before Grinding: 200mm

Size After Grinding: 200 mesh

Passing Rate of Final Product: 98%

Customer’s Comments

We asked the customer for feedback on the entire barite Raymond mill production line, and he gave a fair and high-quality evaluation of our entire service process! The entire process from equipment installation to commissioning, production line layout, finished product quality inspection, etc. was very smooth. It is MR’s mission and commitment to allow customers to use it with peace of mind and confidence.

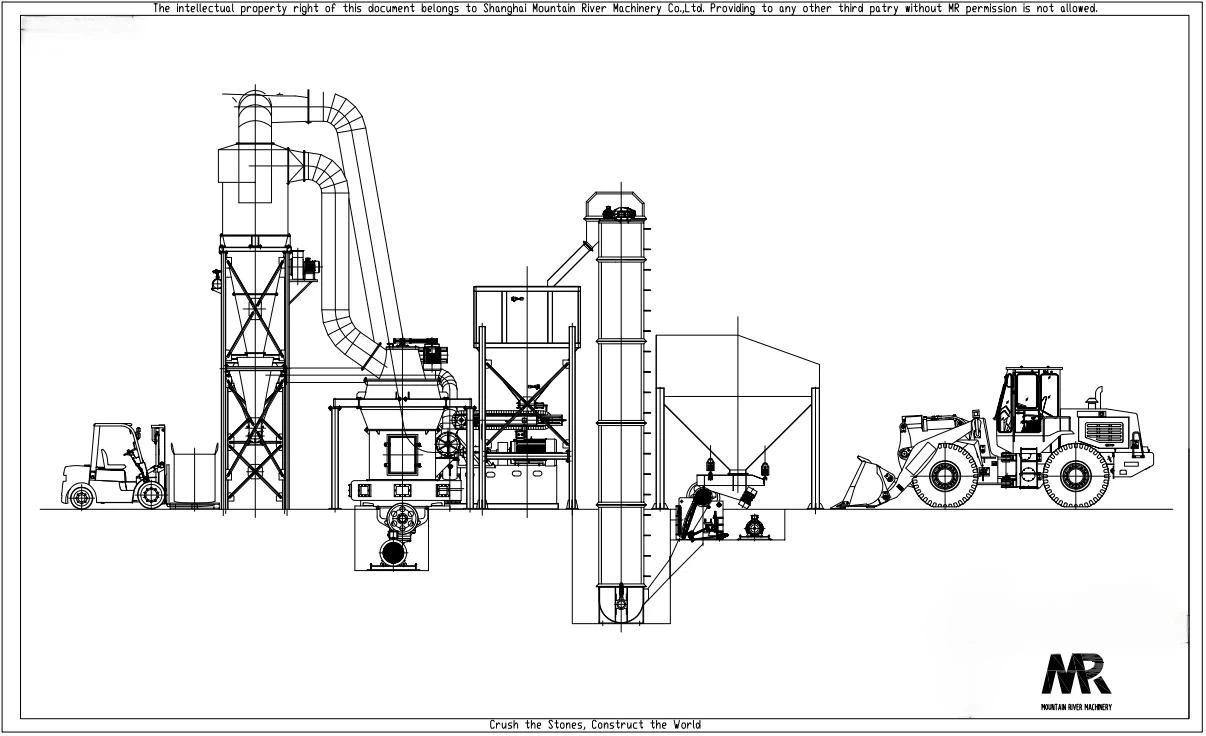

Composition of Raymond Mill Plant

According to the requirements of the project, the barite Raymond Mill production line is composed of jaw crusher, elevator, silo, belt feeder, grinder mill, classifier, tube, cyclone powder collector and pulse dust collector. The most critical part is the main grinder. The crushed barite stones will fall onto the main grinding mill knife seat, and then be scooped up by the knife and fall into the raceway between the grinding rollers and grinding rings. They are squeezed and ground into fine powder by the grinding rollers and grinding rings, and finally form the finished barite powder.

Technical Parameters of Raymond Mill Plant

In our factory, there are 4 models MGW series barite grinding mill for sale: MGW110, MGW138, MGW175, MGW198. This project uses the MGW138 model.

Name & Model | MGW110 | MGW138 | MGW175 | MGW198 |

Roller qty. (pieces) | 4 | 4 | 4/5 | 4/5 |

Outer diameter*height of roller (mm) | Φ360*190 | Φ460*240 | Φ580*280/ Φ520*280 | Φ620*300/ Φ520*300 |

Inner diameter*height of ring (mm) | Φ1100*190 | Φ1380*240 | Φ1750*280 | Φ1980*300 |

Main shaft speed (rpm) | 120 | 96 | 75 | 70 |

Max.feeding size (mm) | <30 | <35 | <40 | <50 |

Output size (mm) | 1.6-0.038 | 1.6-0.038 | 1.6-0.038 | 1.6-0.038 |

Capacity (t/h) | 3.5-10 | 6.5-15 | 13-20 | 15-30 |

Overall dimension (mm) | 8625*7933* 8642 | 9860*8340* 10227 | 13500*11500* 9500 | 15500*12000* 15000 |

Main mill motor (kw) | 55 | 110 | 185 | 280 |

Classifier motor (kw) | 11 | 22 | 37 | 55 |

Blower motor (kw) | 55 | 110 | 200 | 280 |

Jaw crusher | PE250*400 | PE250*750 | PE250*750 | PE250*1200 |

Jaw crusher motor (kw) | 22 | 22 | 22 | 37 |

Bucket elevator | TH200*9M | TH315*9.55M | TH315*11.02M | TH400*12.5M |

Bucket elevator motor (kw) | 3 | 4 | 4 | 7.5 |

Belt feeder (mm) | QB400*2500 | QB500*3000 | QB500*3000 | QB500*6000 |

Belt feeder motor (kw) | 1.5 | 3 | 4 | 4 |

Air block feeder | GF-Φ400 | GF-Φ500 | GF-Φ500 | GF-Φ500 |

Air block feeder motor (kw) | 2.2 | 4 | 5.5 | 5.5 |

Why Does this Customer Want to Grind Barite into Powder?

Barite is a non-metallic mineral with barium sulfate (BaSO₄) as its main component. It has the characteristics of high density, stable chemical properties, and corrosion resistance. The color is mostly white, gray or light yellow. Bolivia is rich in mineral resources, with huge reserves of non-metallic minerals such as barite and limestone. The customer put the large pieces of barite into a jaw crusher for crushing, and then used MGW Raymond mill grinding equipment for grinding, and finally get barite powder 200 mesh. The usage of 200 mesh barite powder is as a mud weighting agent. In the process of oil and gas drilling, by adding barite powder, the density of drilling mud can be significantly increased, and high-density mud can better balance the pressure of underground oil and gas layers and ensure the safety of drilling operations.

Bolivia is rich in mineral resources, with huge reserves of non-metallic minerals such as barite and limestone. The customer put the large pieces of barite into a jaw crusher for crushing, and then used MGW Raymond mill grinding equipment for grinding, and finally get barite powder 200 mesh. The usage of 200 mesh barite powder is as a mud weighting agent. In the process of oil and gas drilling, by adding barite powder, the density of drilling mud can be significantly increased, and high-density mud can better balance the pressure of underground oil and gas layers and ensure the safety of drilling operations.

During the drilling process, barite powder can help cool the drill bit to prevent it from being damaged by high temperature.

In addition, barite powder has the following other uses:

Chemical industry: 60 mesh. Used in the production of barium salt compounds, such as barium carbonate, barium chloride, etc., as fillers for paints, coatings, plastics and other industries to improve product performance.

Petroleum industry: 150-325 mesh. As a weighting agent for drilling mud, it increases mud density and prevents blowouts.

Rubber industry: above 325 mesh. High-fineness barite powder plays an important role in the rubber, plastic and paint industries, enhancing the physical properties of products and increasing service life.

High-purity barite powder can also be used in the pharmaceutical industry as a raw material for x-ray contrast agents, and in the electronics industry it can also be used to make electronic components such as picture tubes and capacitors.