MGW Raymond Mill Heavy Calcium Carbonate Production Line

MGW Raymond mill is a high-efficiency grinding equipment widely used in non-metallic minerals, building materials, chemical industry and other industries. It is mainly composed of main mill, classifier, fan, cyclone, tube, motor, etc.

Are you Still Worried About the Low Efficiency of Powder Processing?

MGW Raymond Mill to Help You!

MGW Raymond mill is a high-efficiency grinding equipment widely used in non-metallic minerals, building materials, chemical industry and other industries. It is mainly composed of main mill, classifier, fan, cyclone, tube, motor, etc.

MGW grinding mill can grind non-flammable and explosive non-metallic materials with Mohs hardness not more than level 9 and humidity below 6% into 80-400 mesh powder. The environmentally friendly and pollution-free MGW grinder has high grinding efficiency and low energy consumption with its high-quality materials and advanced manufacturing technology. It saves 30%-50% energy compared with traditional ball mills. In addition, the equipment has stable and reliable operation, low failure rate and long service life. It has become the first choice for grinding non-metallic minerals into powder. Heavy Calcium Carbonate is one of the powders ground by MGW Raymond mill

Heavy Calcium Carbonate (GCC)– the “White Treasure” You May Not Know!

What is heavy calcium carbonate (GCC)?

Heavy calcium carbonate is obtained by processing, crushing and grinding natural limestone. Its main component is CaCO₃ (calcium carbonate), which is usually white or off-white powder and is widely used in many industries, especially fillers and pigments. Due to its good physical properties and chemical stability, heavy calcium carbonate is widely used in many fields. It can be used as a filler for paper to improve the smoothness, whiteness and printing performance of paper, as an admixture in cement and concrete to improve the strength and durability of the product, and as a filler for plastics to improve the processing performance of plastics, reduce costs, and increase strength and rigidity, etc. Therefore, Heavy calcium carbonate is also called a multifunctional industrial raw material – a widely used “white gold”.

Heavy Calcium Carbonate Rocks Transform into Powder

Revealing the Secrets of Raymond Mill Production Line

As the name implies, the Raymond mill production line is a complete production system that uses Raymond mill as the core to process raw materials into powder of the required fineness. This production system includes the following stages:

(1) Raw material pretreatment stage: jaw crusher, elevator, silo, skirt belt feeder, air lock feeder, etc.;

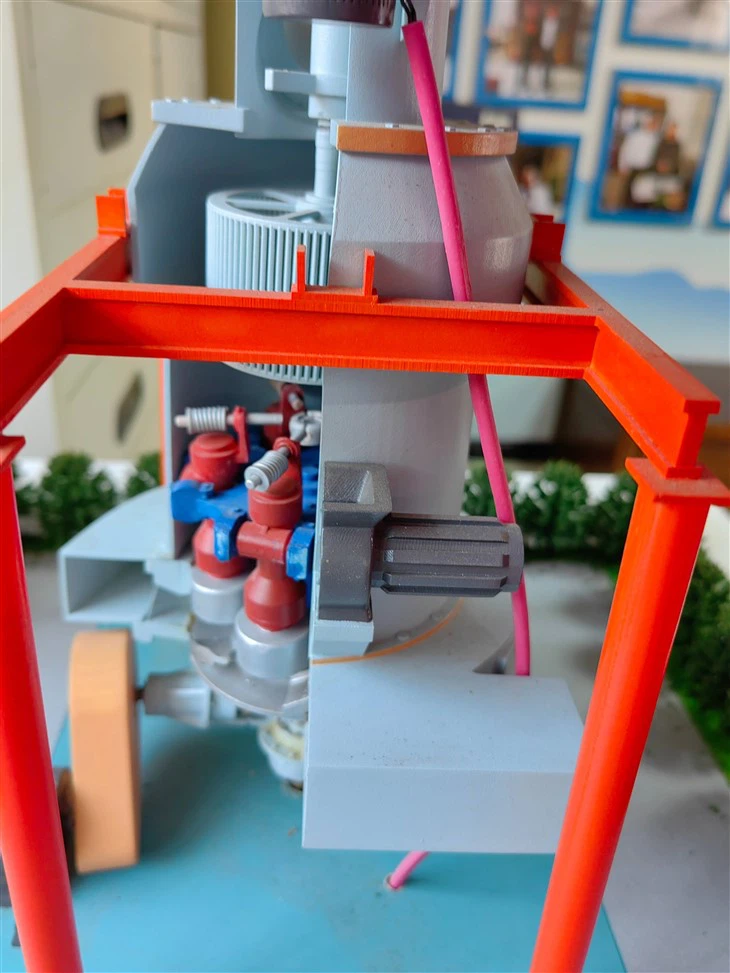

(2) Grinding stage: Raymond mill main mill, classifier inside the main mill, spider, knife, knife seat, grinding roller, grinding ring, etc.;

(3) Finished product collection stage: cyclone powder collector, pulse bag filter, screw conveyor, etc.

The efficient coordination of equipment in each stage forms a systematic Raymond grinder production line, thereby producing finished powder that meets the particle size requirements.

Technical Parameters of MGW Raymond Mill

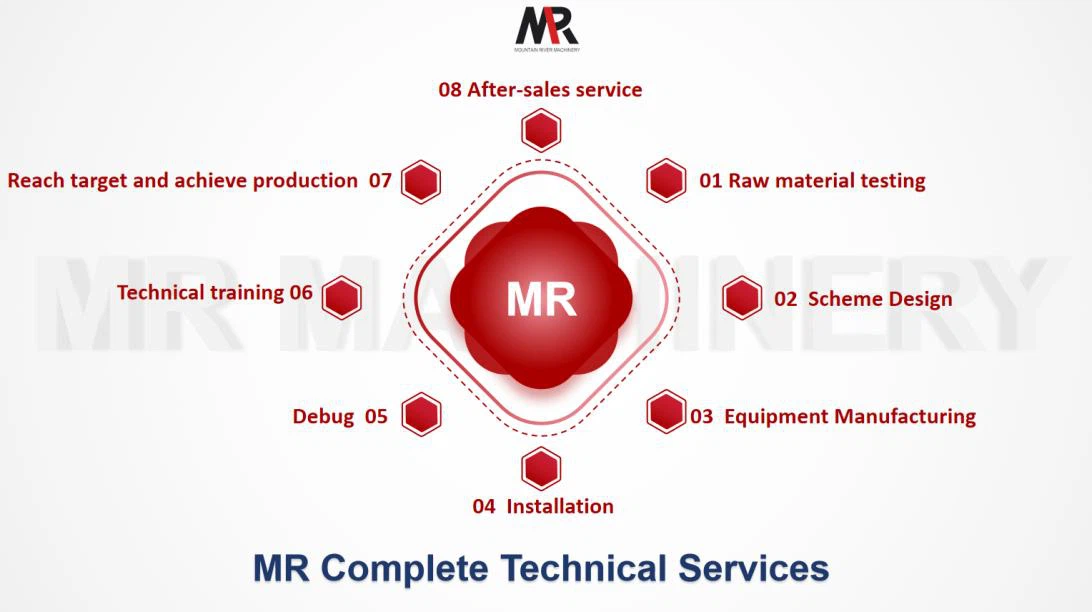

MR Complete Service Process