Dolomite Grinding Mill

MTW raymond mill is suitable for processing various non-flammable and non-explosive mineral materials with Moh’s hardness lower than 9. It is widely used in the fields of metallurgy, construction, chemical industry and so on.

Composition of Whole Plant of Dolomite Raymond Mill

A complete MGW dolomite raymond mill plant consists of:

(1) Jaw Crusher | (2) Bucket Elevator | (3) Hopper | (4) Vibrating Conveyor | (9) Blower |

(5) Main Mill | (6) Classifier | (7) Cyclone | (8) Bag filter |

Working Principle

The whole process is divided into: crushing, grinding, grading, and grinding again. Large pieces of material are first sent to the jaw crusher for pre-crushing, and the material crushed to about 20mm by the jaw crusher is sent to the hopper via the bucket elevator, and a vibrating feeder is installed below the hopper. The vibrating feeder will send the material evenly and quantitatively to the main raymond mill continuously for grinding. The material fed into the main unit of the mill by the feeder will be ground into powder by the grinding roller and grinding ring in the cavity of the mill. The fine powder that meets the fineness requirements will enter the cyclone powder collector through the pipeline with the airflow, and then discharged through the discharge valve to become the finished product. The powder that does not meet the fineness requirements will fall into the mill for regrinding.

Technical Advantages

(1) Automatic light oil lubrication + water cooling constant temperature system makes the equipment stable and reliable, and the service life is increased by 5-10 times.

There is an advanced and reliable built-in thin oil lubrication and circulating water cooling system inside the machine. The internal oil pump adopts a closed gear box, which can lubricate the main shaft bearing and the bevel gear shaft bearing, automatically supply oil, and transmit easily. The circulating water cooling system ensures the constant temperature of the main shaft and bearing and prolongs the service life of the equipment.

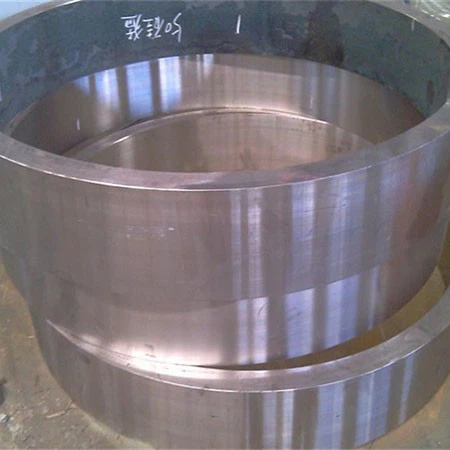

(2) Special structure design of grinding roller, grinding ring and shovel blade, using high wear-resistant material.

Important spare parts are made of high-quality steel. The blade material of the shovel adopts high wear-resistant silicon-manganese alloy. Just replace the blade. The curved blade can guide the material to the vertical surface, so that the upper, middle and lower parts of the grinding roller ring can be ground, so that it can wear evenly, increase the effective working area, improve the grinding efficiency, thereby increasing the output and reducing the use of The cost, the theoretical life is 5-10 times that of the old-fashioned blade.

(3)Advanced closed circulation system, dust removal and noise reduction, environmentally friendly choice.

The air flow system of the whole machine circulates in a closed state of positive and negative pressure. The unique air self-circulation system greatly reduces the amount of dust in the external exhaust air. It is equipped with advanced dust collectors with low noise and fully meets environmental protection standards.

Technical Parameters

Name & Model | MGW110 | MGW138 | MGW175 | MGW198 |

Roller qty. (pieces) | 4 | 4 | 4/5 | 4/5 |

Outer diameter*height of roller (mm) | Φ360*190 | Φ460*240 | Φ580*280/ Φ520*280 | Φ620*300/ Φ520*300 |

Inner diameter*height of ring (mm) | Φ1100*190 | Φ1380*240 | Φ1750*280 | Φ1980*300 |

Main shaft speed (rpm) | 120 | 96 | 75 | 70 |

Max.feeding size (mm) | <30 | <35 | <40 | <50 |

Output size (mm) | 1.6-0.038 | 1.6-0.038 | 1.6-0.038 | 1.6-0.038 |

Capacity (t/h) | 3.5-10 | 6.5-15 | 13-20 | 15-30 |

Overall dimension (mm) | 8625*7933* 8642 | 9860*8340* 10227 | 13500*11500* 9500 | 15500*12000* 15000 |

Main mill motor (kw) | 55 | 110 | 185 | 280 |

Classifier motor (kw) | 11 | 22 | 37 | 55 |

Blower motor (kw) | 55 | 110 | 200 | 280 |

Jaw crusher | PE250*400 | PE250*750 | PE250*750 | PE250*1200 |

Jaw crusher motor (kw) | 22 | 22 | 22 | 37 |

Bucket elevator | TH200*9M | TH315*9.55M | TH315*11.02M | TH400*12.5M |

Bucket elevator motor (kw) | 3 | 4 | 4 | 7.5 |

Belt feeder (mm) | QB400*2500 | QB500*3000 | QB500*3000 | QB500*6000 |

Belt feeder motor (kw) | 1.5 | 3 | 4 | 4 |

Air block feeder | GF-Φ400 | GF-Φ500 | GF-Φ500 | GF-Φ500 |

Air block feeder motor (kw) | 2.2 | 4 | 5.5 | 5.5 |

FAQ

In order to choose the correct model for you, what information shall be requested from you?

(1) What kind of raw material do you want to grind? Do you have a picture of your raw material?

(2) What is the original size of your raw mineral before feeding into the grinding mill? And what is the moisture?

(3) What capacity do you need per hour? How many tons per hour?

(4) After grinding, what size do you want to get? For example, 200 mesh, 325 mesh, etc.

How long is your delivery time?

20 working days upon receiving the down payment of the Contract.

What is your terms of payment?

30% of the total contract value shall be paid by T/T as down payment, 70% of the total contract value shall be paid by T/T after the buyer receives the notice of the seller that the products are ready.