High-efficiency Pendular Mill For Grinding Fertilizers

The fertilizer powder produced by the Raymond mill machine will be used for fertilizer granulation.

Why does Our Customer Wants to Grind Fertilizer into Powder? What is the Use of Grinded Fertilizer Powder?

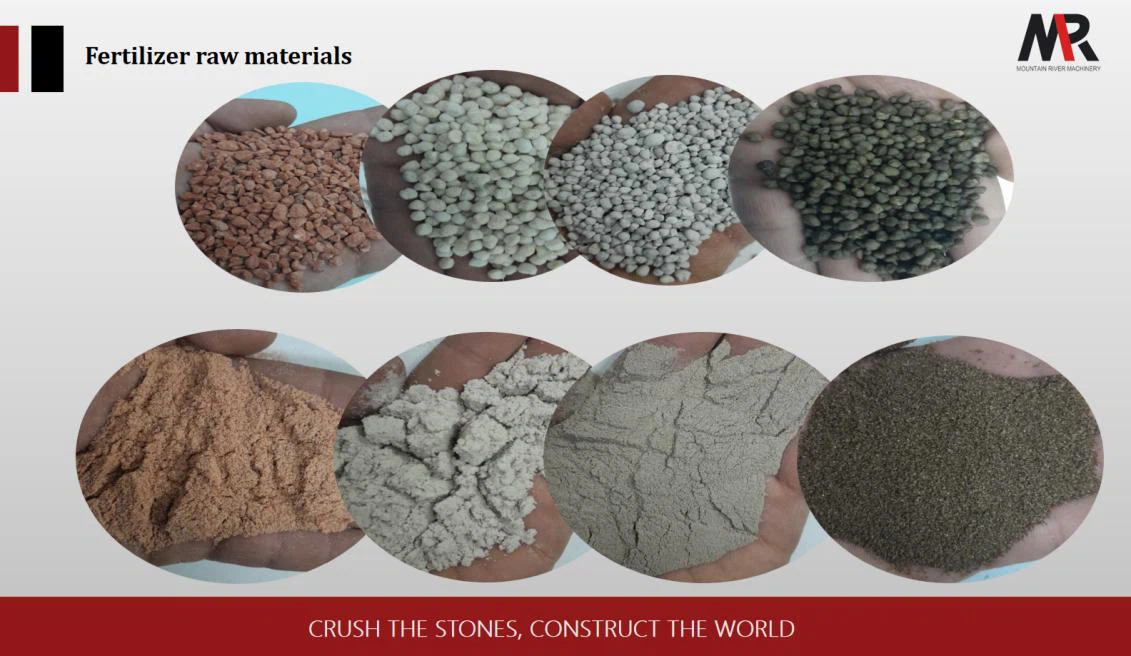

Recently, some customers have purchased our Raymond mill for fertilizer recycling. For example, a customer Mr. D in South America has SSP (calcuim superphosphate), TSP (triple superphosphate), KCL (potassium chloride powder), MAP (monoammonium phosphate), etc.

After the fertilizer granulation, our customer Mr. D got some unqualified fertilizer pellets, such as 1mm powder, 1-6mm particles. These fertilizer particle sizes can not meet the market requirements, because some of them are too big or too small. If the size does not meet the standard, it will be thrown away and thus waste resources.

Therefore, the customer wants to collect these fertilizers and grind these particles into 80 mesh powder again to form the best fertilizer powder.

Project Information

Raw material : Fertilizer, SSP (calcuim superphosphate), TSP (triple superphosphate), KCL (potassium chloride powder), MAP (monoammonium phosphate)

Raw material size: 1-6mm particles, 1mm powder

Finished product:80 mesh, passing rate 95%

Output: 15-20 tons/hour

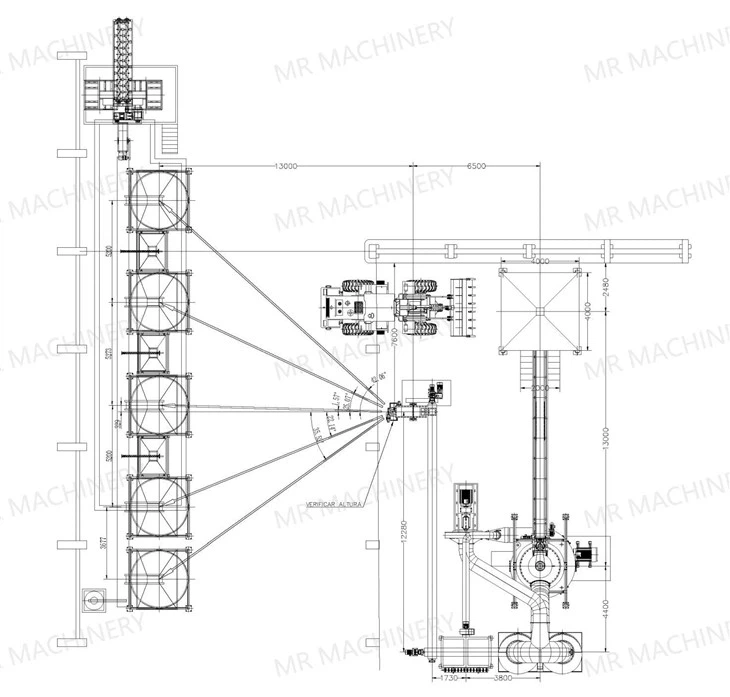

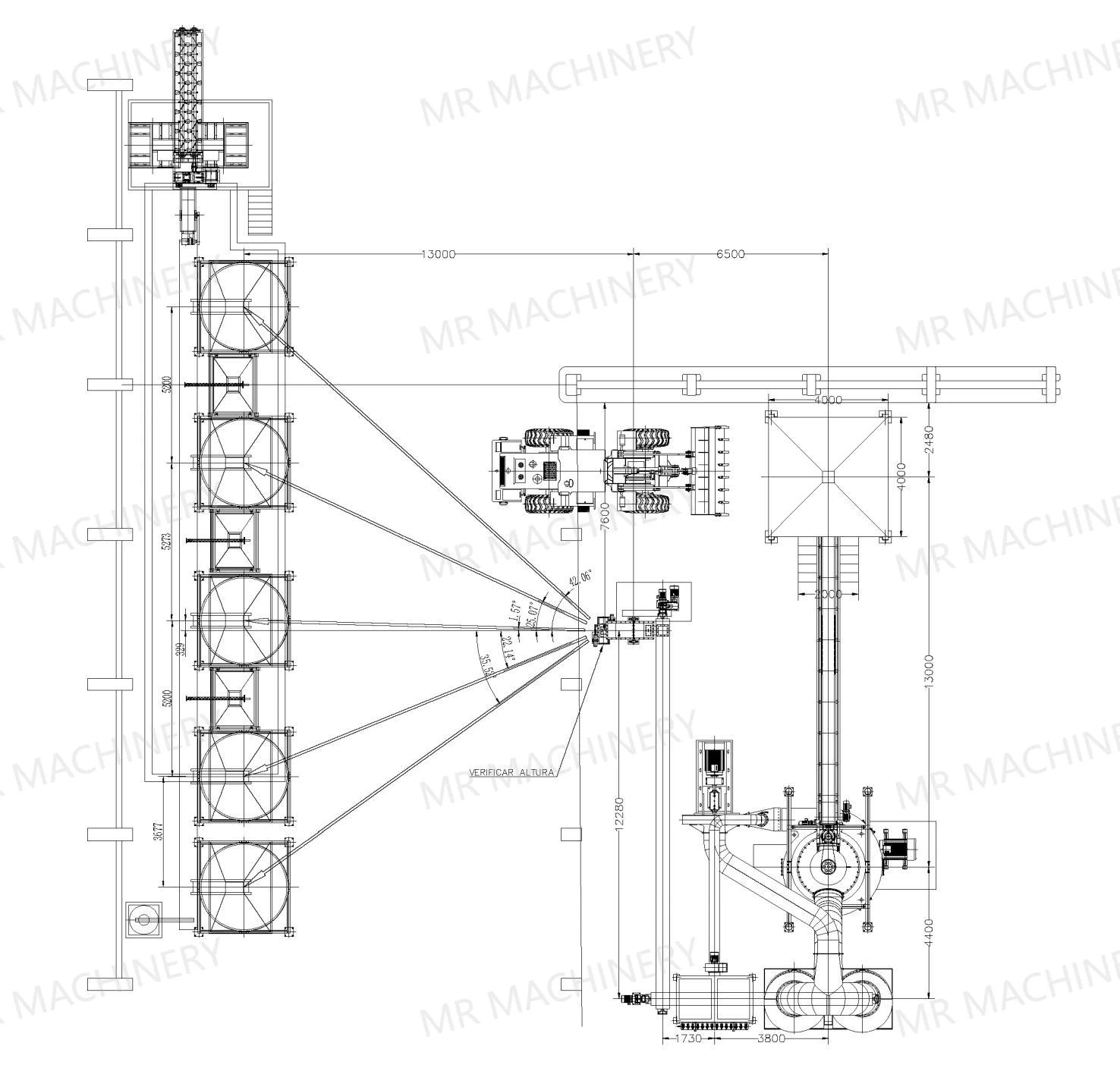

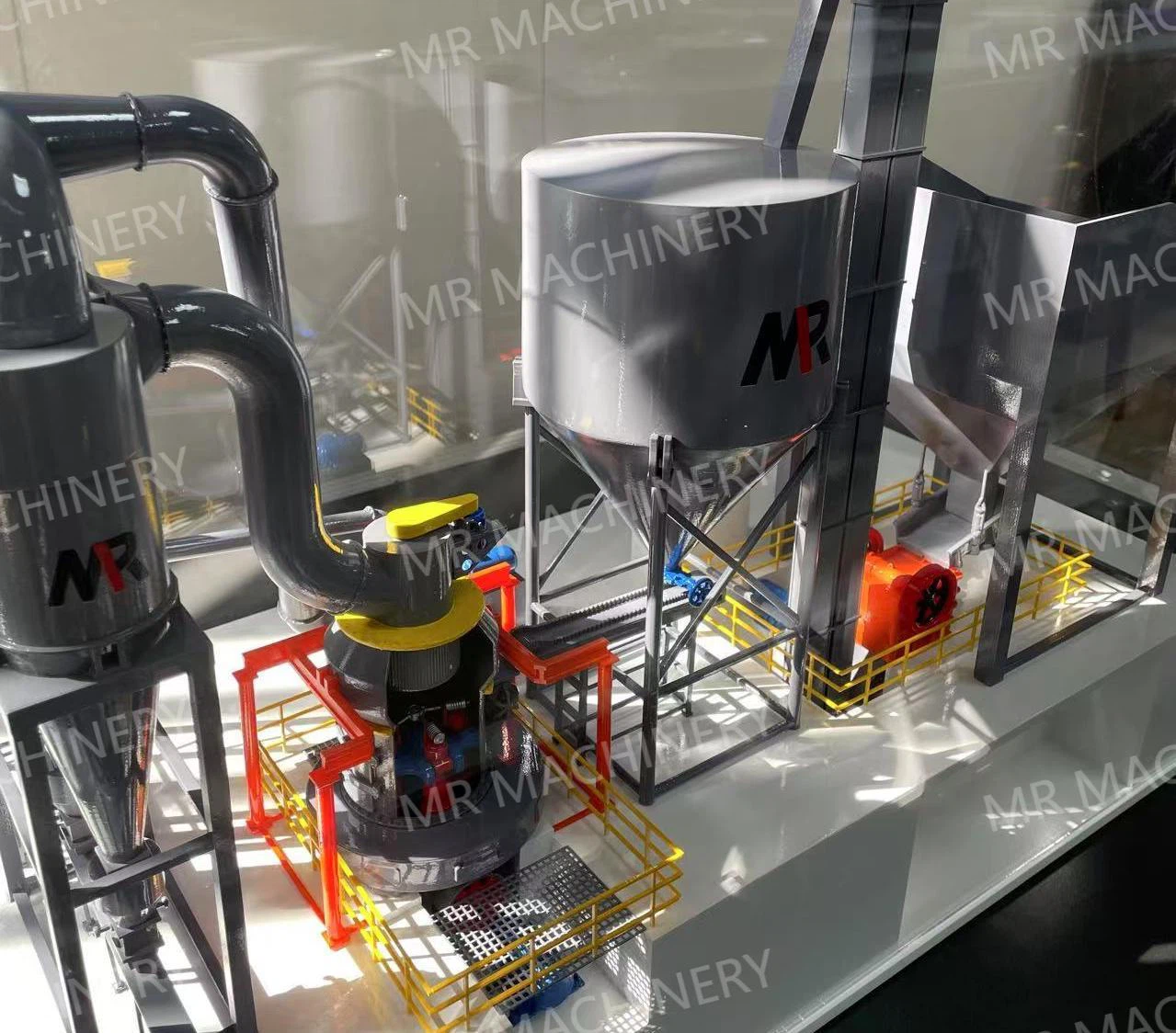

The equipment we recommend to customers is a complete fertilizer grinding machine MGW175. The specifications of our MGW175 are as follows:

Model | MGW175 |

Roller qty. (pieces) | 4/5 |

Outer diameter*height of roller (mm) | φ580*280 |

Inner diameter*height of ring (mm) | φ1750*280 |

Main shaft speed (rpm) | 75 |

Max.feeding size (mm) | <40 |

Output size (mm) | 1.6-0.038 |

Capacity (t/h) | 13-20 |

Overall dimension (mm) | 13500*11500*9500 |

Main mill motor (kw) | 185 |

Classifier motor (kw) | 37 |

Blower motor (kw) | 200 |

Jaw crusher | PE250*750 |

Jaw crusher motor (kw) | 22 |

Bucket elevator | TH315*11.02M |

Bucket elevator motor (kw) | 4 |

Belt feeder (mm) | QB500*3000 |

Belt feeder motor (kw) | 4 |

Air block feeder | GF-Φ500 |

Air block feeder motor (kw) | 5.5 |

When Designing this Grinding Production Line for Mr. D, What Small Special Designs do we Offer?

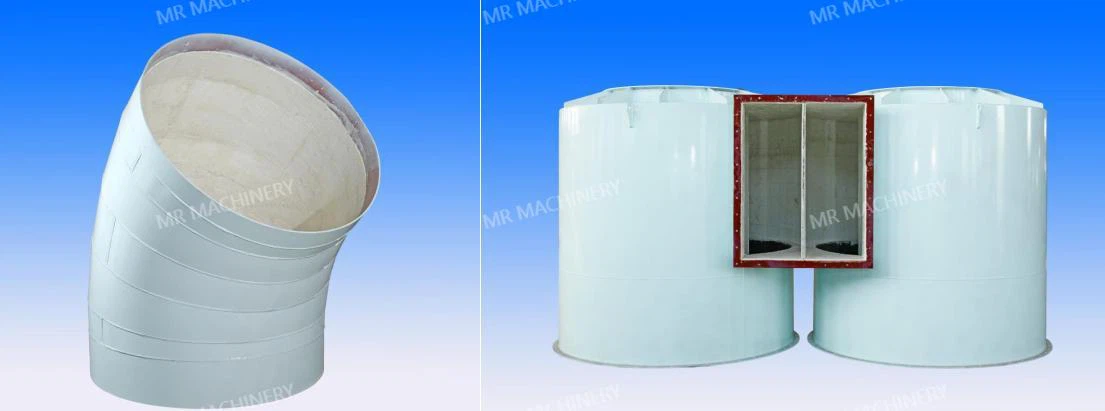

1. Apply wear-resistant ceramic patches:

The finished product required by the customer is 80 mesh, which is a coarse powder. Therefore, we pasted wear-resistant ceramics at the two elbows of the powder classifier of the fertilizer grinding machine, the upper part of the cyclone cylinder and the square junction and other places.

These wear-resistant ceramics can effectively prevent the elbow of the raymond mill classifier and the upper part of the cyclone cylinder from being worn through by the rapidly passing fertilizer powder, and play a protective role. In what other situations do we need to paste wear-resistant ceramics?

When the hardness of the customer’s raw material exceeds 3, or the customer wants to get a powder coarser than 200 mesh after grinding, we will recommend wear-resistant ceramic patches to the customer.

The role of wear-resistant ceramic patches:

- Ceramics are harder than steel and can resist the erosion of high-speed powder airflow. They are not easy to wear and can effectively reduce the frequency of powder grinding mill tube replacement.

- Ceramics are chemically inert and resistant to acid and alkali corrosion, avoiding pollution and blockage of grinding equipment iron tube caused by corrosion of fertilizers (such as phosphates and potassium chloride).

- The smooth ceramic surface reduces powder adhesion, ensures grinding mill tube smooth airflow, and maintains stable wind pressure and output

2. The main Fain, the main mill, the classifier, and the skirt belt feeder are all equipped with frequency converters, which can create the following advantages during the grinding process:

Main fan with frequency converter:

①Automatic adjustment of air volume.

②Reactive power compensation.

③Save about 15% of electricity.

Main mill with frequency converter:

①Our customer Mr. D has 4 different types of raw material, SSP, TSP, KCL, MAP, etc. When different raw material is fed into the grinder, with the help of main mill frequency converter, the working speed of the main grinder can be different automatically.

②Reduce vibration and damage to the mill.

Classifier with frequency converter:

①Classify different fineness of final product.

3.Computer integrated control and manual control dual mode

①Manual button+fully automatic computer control system, one-touch start.

②Uniform speed feeding, avoid collision between rollers&ring, extend service life of the machine.

③If a system failure occurs, the computer will automatically sound an alarm and the entire line will automatically shut down, reducing damage to the machine.

④Higher production capacity, more benefit of selling fine powder.

The electronic control system developed by our MR is the most highly automated system among all the grinding mill suppliers in the country.

The Raymond mill developed by us MR is the heaviest, has the largest dimensions, uses the best materials, and has the highest production cost among all the grinding mill suppliers in the country.

Some Photos of MGW175 Delivery