Calcium Oxide Raymond Mill

Send InquiryIntroduction

Calcium oxide Raymond mill can be widely used in mines and chemical plants. It is the most common type of mining grinding machine. It can grind various mining materials, for example, calcium oxide, barite, calcite, limestone, talc, marble, activated carbon, bentonite, cement, kaolin, apatite, glass, bluestone, petroleum coke and more than 280 kinds of non-flammable and explosive minerals. Raymond mill works efficiently through the cooperation of the grinding roller, grinding ring and classifier in the main grinder. The raw materials entering the mill will be ground into powder under the strong pressure of the interaction between the grinding roller and grinding ring. The powder of suitable size will be precipitated by the classifier into the air duct and finally reach the powder collector. The unsuitable powder will fall back between the grinding roller and grinding ring because it can not pass the classifier and continue to be ground.

Composition

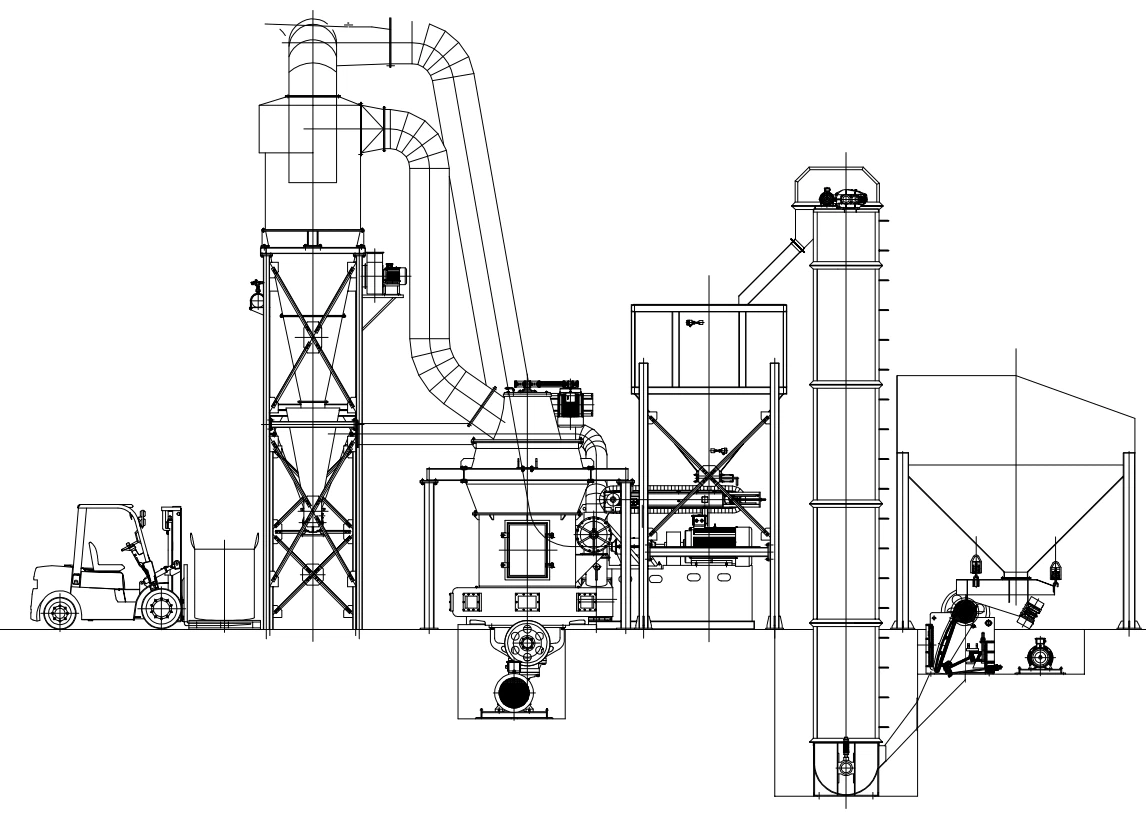

Calcium oxide Raymond mill is a vertical mill that has been improved in design. Its grinding line consists of jaw crusher, bucket elevator, storage silo, vibrating feeder, belt feeder, air duct, cyclone, fan, pulse dust collector. Raymond mill is composed of main mill,classifier, blade, blade seat, grinding roller, grinding ring, grinding roller hanger, bevel gear, arc air duct.

Main mill: The main machine is the core component of Raymond mill. It includes grinding roller, grinding ring and other parts for grinding and powder selection. The main mill is mainly responsible for the entry of raw materials and the precipitation of finished products. It is an important structure of Raymond mill.

Grinding roller & Grinding ring: The grinding roller is a roller mounted on the grinding roller hanger, and the grinding ring is a ring fixed on the main machine around the circular track inside the main machine. When the main grinder is started, the grinding roller will press against the grinding ring to crush and grind the material, thus forming fine powder.

Blade: The scraper is an arc-shaped blade that is close to the circular track. It will shovel the powder or raw material left on the circular track and send it to the middle of the grinding roller and grinding ring for secondary grinding, so that the powder will not accumulate on the circular track and cause a decrease in production.

Curved air duct: The fan blows air from the curved air duct, so that the air flow inside the main machine is ascending, which can blow the ground powder into the air duct through the classifier.

Classifier: Responsible for controlling the size of the powder. The powder of the appropriate size will enter the air duct through the classifier to form a finished product, and the unsuitable powder will return to the main machine for further grinding.

Technical Parameters

Name & Model | MGW110 | MGW138 | MGW175 | MGW198 |

Roller qty. (pieces) | 4 | 4 | 4/5 | 4/5 |

Outer diameter*height of roller (mm) | Φ360*190 | Φ460*240 | Φ580*280/ Φ520*280 | Φ620*300/ Φ520*300 |

Inner diameter*height of ring (mm) | Φ1100*190 | Φ1380*240 | Φ1750*280 | Φ1980*300 |

Main shaft speed (rpm) | 120 | 96 | 75 | 70 |

Max.feeding size (mm) | <30 | <35 | <40 | <50 |

Output size (mm) | 1.6-0.038 | 1.6-0.038 | 1.6-0.038 | 1.6-0.038 |

Capacity (t/h) | 3.5-10 | 6.5-15 | 13-20 | 15-30 |

Overall dimension (mm) | 8625*7933* 8642 | 9860*8340* 10227 | 13500*11500* 9500 | 15500*12000* 15000 |

Main mill motor (kw) | 55 | 110 | 185 | 280 |

Classifier motor (kw) | 11 | 22 | 37 | 55 |

Blower motor (kw) | 55 | 110 | 200 | 280 |

Jaw crusher | PE250*400 | PE250*750 | PE250*750 | PE250*1200 |

Jaw crusher motor (kw) | 22 | 22 | 22 | 37 |

Bucket elevator | TH200*9M | TH315*9.55M | TH315*11.02M | TH400*12.5M |

Bucket elevator motor (kw) | 3 | 4 | 4 | 7.5 |

Belt feeder (mm) | QB400*2500 | QB500*3000 | QB500*3000 | QB500*6000 |

Belt feeder motor (kw) | 1.5 | 3 | 4 | 4 |

Air block feeder | GF-Φ400 | GF-Φ500 | GF-Φ500 | GF-Φ500 |

Air block feeder motor (kw) | 2.2 | 4 | 5.5 | 5.5 |

Green and Environmental Protection

The Raymond mill improved by our excellent scientific research and technical team has made great contributions to environmental protection. The dust pollution at the production site has been greatly reduced, which is beneficial to the original environment and the respiratory health of the on-site workers. In addition, the improved Raymond mill has the advantages of simple operation and energy saving, and is one of the best choices for mining equipment. If you want to know more about our Raymond mill, you can contact +8615821910712.