1830×7000 Ball Mill For Feldspar Grinding

Ball mill can grind materials into powder. It is widely used in cement, silicate products,ferrous and non-ferrous metal beneficiation, glass and ceramics and other production industries.

Introduction

Ball mill is a key equipment for grinding materials again after crushing.It is widely used in mining, cement, silicate products, glass and ceramics and other production industries. This article mainly introduces a feldspar grinding project that we MR have done. The key machine is ball mill 1830*7000.

Project Information

Raw Material: Feldspar

Original size before grinding: ≤10mm

Final size after grinding: 200#, 99% passing rate

Capacity: 4-5 tons per hour.

Usage of final size: Regulate the pH value of the soil, improve the soil structure, promote plant growth and development, and provide nutrients for plants.

Mining equipments recommended: ball mill 1830*7000, classifier, bag filter, cyclon, elevator, belt conveyor, etc.

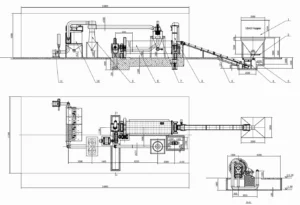

MR Design Of Ball Mill Feldspar Grinding Plant

Explaination Of Ball Mill Feldspar Grinding

The original size of the feldspar is 10mm. It will be sent to the 12m3 hopper by excavators. Then the feldspar stones will be ttransported to the elevator by a belt conveyor. The elevator will feed the feldspar into the elevator 1800*7000 for grinding. After grinding, the classifier will be select 200 mesh as final product, and the oversize will be sent to the elevator to be ground again.

Technical Parameters

Model | Φ1830×7000 |

Capacity (t/h) | 4-5 @ 200mesh |

Feeding size (mm) | ≤25 |

Feeding moisture (mm) | 20-30% |

Rotation speed (r/min) | 21.4 |

Ball loading (t) | 15 (Al2O3≥92%) |

Main motor power (KW) | 245 |

Main motor model | JR137-8/245 |

Main motor speed (r/min) | 740 |

Main motor gearbox model | ZD60 |

Bearing type | Self-aligning roller bearing |

Shell material | Q235B |

Liner material | ZGMnl3Cr2 |

Gear material | ZG310-570 |

Pinion material | 40Cr conditioning |