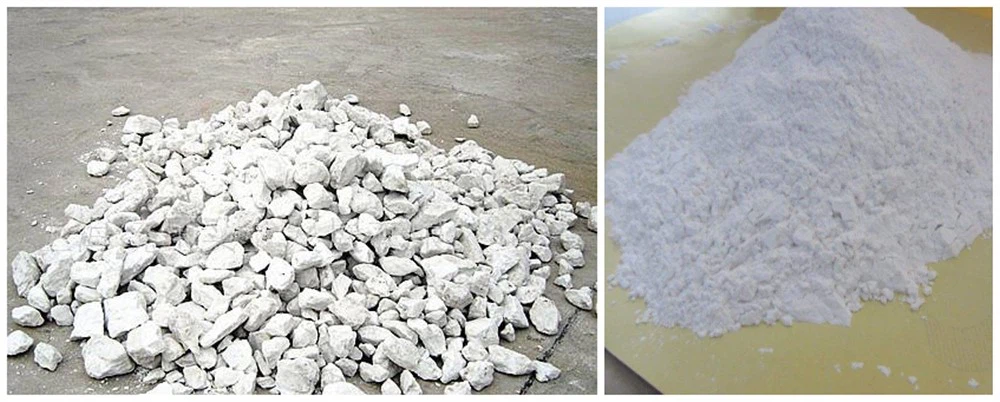

Barite Grinding Raymond Mill

MGW raymond mill is suitable for processing various non-flammable and non-explosive mineral materials with Moh’s hardness lower than 9. It is widely used in the fields of metallurgy, construction, chemical industry and so on.

Application Of Barite Raymond Mill

MGW series barite raymond mill is the result of MR’s technological revolution to the traditional Raymond mill. The production capacity is 30-40% higher than that of the traditional Raymond mill. It can meet the growing demand for industrial scale production. It can grind a wide range of materials and is suitable for Mohs hardness. Various non-flammable and explosive materials below grade 7 and humidity within 6%.

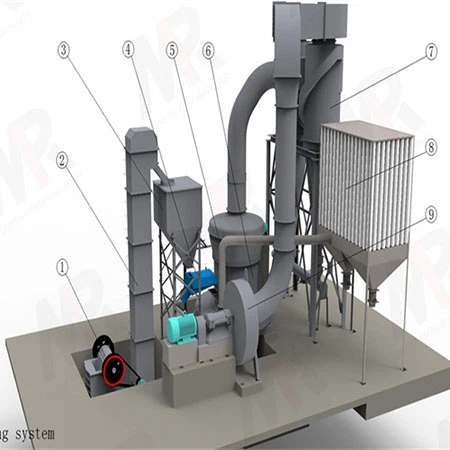

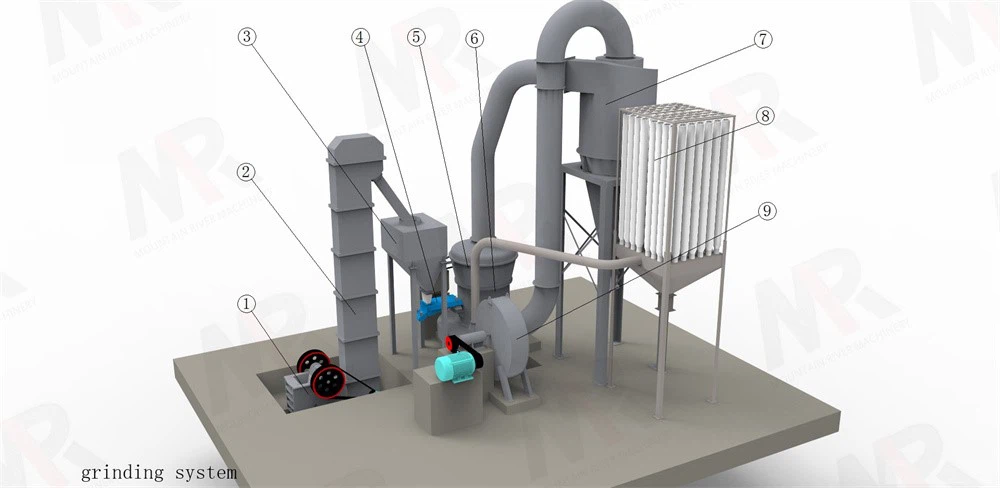

Composition of Whole Plant

A complete MGW barite raymond mill plant consists of:

(1) Jaw Crusher | (2) Bucket Elevator | (3) Hopper | (4) Vibrating Conveyor | (9) Blower |

(5) Main Mill | (6) Classifier | (7) Cyclone | (8) Bag filter |

Technical Advantages

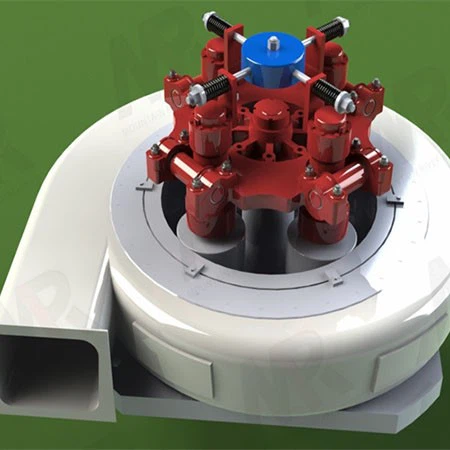

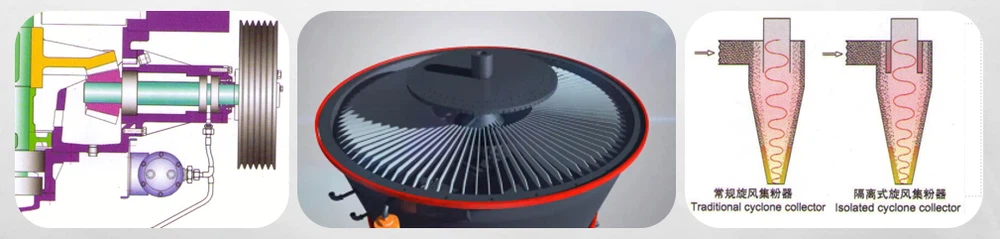

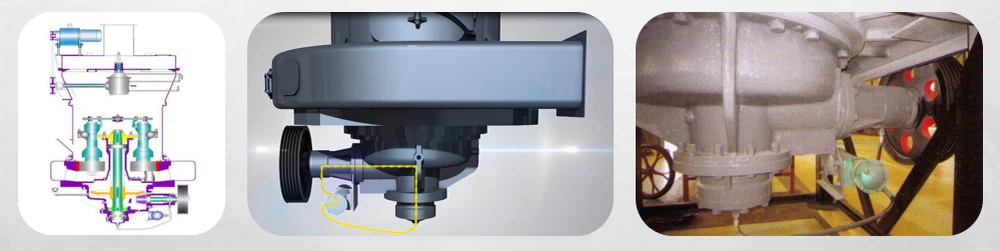

The high-end configuration of bevel gear integral drive + frequency conversion classifier + isolation powder collection greatly improves the powder selection efficiency.

(1)The bevel gear is used for integral transmission, without the reducer, which improves the work efficiency.

(2) Using frequency conversion to control the rotation speed of the classifier, the powder selection effect is better.

(3)The isolated cyclone powder collector is used to greatly improve the powder selection efficiency.

(4) Automatic light oil lubrication + water cooling constant temperature system makes the equipment stable and reliable, and the service life is increased by 5-10 times. There is an advanced and reliable built-in thin oil lubrication and circulating water cooling system inside the machine. The internal oil pump adopts a closed gear box, which can lubricate the main shaft bearing and the bevel gear shaft bearing, automatically supply oil, and transmit easily. The circulating water cooling system ensures the constant temperature of the main shaft and bearing and prolongs the service life of the equipment.

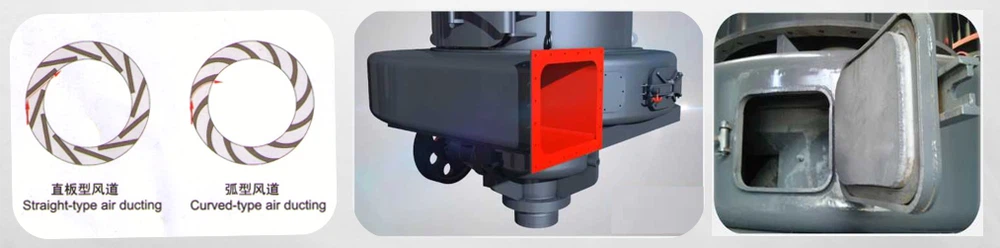

(5) The radian design of the inner and outer surfaces makes it popular without hindrance and improves the efficiency. The overall use of curved surface design, arc-shaped air duct, no resistance to the air inlet volute, no airflow dead angle, material flow unimpeded. Observe that the inner surface of the door panel and the inner surface of the air inlet volute are on the same curved surface to avoid eddy current effects and reduce energy consumption. The appearance also adopts a beautiful arc design, which is beautiful and safe.

Sample Plant

Raw material: barite

Input size: 200mm

Output size: 200 mesh

Time of operation: 10 hours per day

Model of Raymond grinding mill:MGW175

Capacity: 20-25 tons per hour

MR After Sales Service

Step 1, Production Order

After receiving down payment from our customers, our sales will inform our customers immediately and reconfirm the basic requirements of the machine configuration, voltage, hertz, area where the machine will be installed, color of the machine, etc. According to this information, our sales will send the production order to our factory to start production immediately.

Step 2, Foundation Drawing

Our technical department will start making foundation drawings and layout drawing. And our sales will send foundation plans, installation instructions, complete electrical diagram of the plant after 5 (five) working days after the down payment is received.

Step 3, Continuous Follow-up of Production

In the process of production of equipment, our sales will notify customers of the progress of stocking up every two weeks, and send relevant photos and videos to our customers, so that customers can understand the production situation of our factory.

Step 4, Machinery Test in MR factory

When the equipment is ready, we will test the machine in our factory, and our sales will send the video and photos of the test machine to our customers and inform our customer to make balance payment.

Step 5, Load Products & Logistics

After receiving the balance payment from our customers, we will book shipping and load our machinery and transport them to the port.

Step 6, Confirming Custom Clearance Documents with Our Customers

After sending the products, we will prepare some documents which will be used when our customer make custom clearance. For example, bill of lading, commercial invoice, packing list, certificate of origin, etc. We will prepare draft documents and confirm with our customers one by one. If our customers need some special documents, they should also inform us as earlier as they can.

Step 7, Dispatching MR Engineer for Installation

The buyer is responsible for civil engineering, accessory materials, crane, light and power supply, and other necessary things. The technician is one person and he will guide the installation and train local workers to operate the machine. The buyer shall pay the salary for our technician, as well as round-trip tickets, lodging, food, personal insurance, communication cost, etc. The buyer must ensure the safety and freedom of the technician during the installation.

Step 8, Continuous Follow Up & Spare Parts Supply

After your production line is working, we will follow up your production every month. We will consult the consumption of spare parts of your machinery and we are ready to send you the spare parts as soon as possible!