Micro-powder Grinding Mill

Send InquiryIntroduction of Micro-powder Grinding Mill

Micro-powder grinding mill is a kind of equipment that can grind solid materials into powder. It is often used in metallurgy, building materials, chemical industry, mining and other industries.

Capacity: 0.5-45 tons per hour

Input size: maximum 20mm.

Output size: 325 mesh to 3000 mesh, 5 microns to 47 microns

Usage of final product from micro-powder grinding mill: painting, coating, paper making, PVC making, toothpaste making, drilling mud, additive in chemical and plastic, high quality paper as additive, etc.

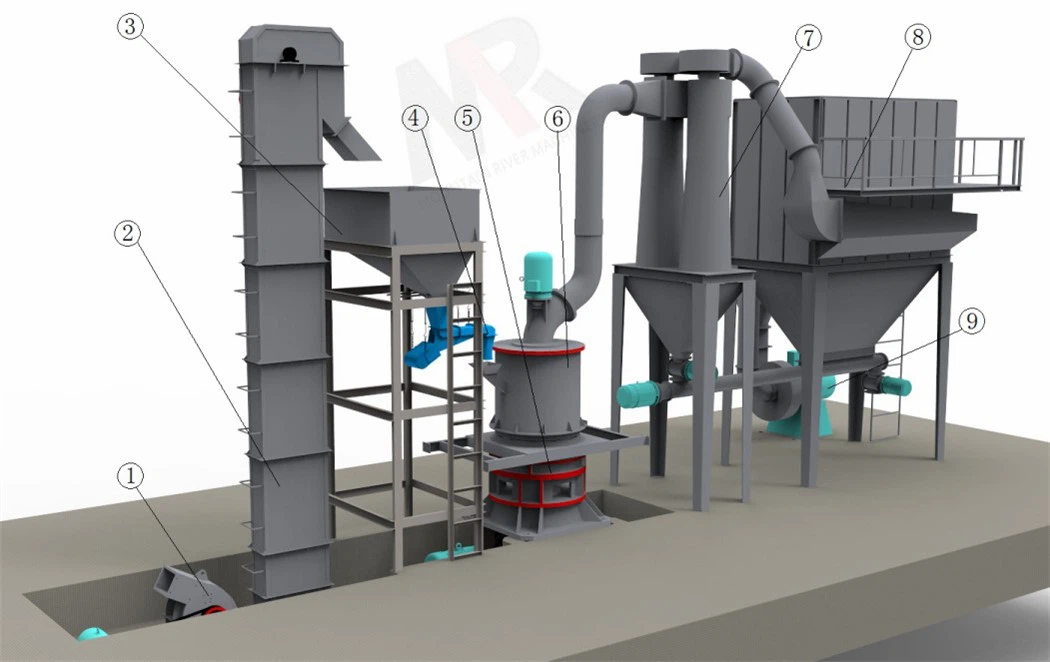

Composition

A Complete MSF Micro Powder Grinding Mill Consists Of:

(1) Hammer Crusher | (2) Elevator | (3) Hopper | (4) Belt Conveyor | (9) Blower |

(5) Main Mill | (6) Classifier | (7) Dust Collector | (8) Pulse Dust Filter |

Technical Advantages

High safety and reliability

There is no rolling bearing and screw in the main mill cavity, so the user does not need to worry about the wear and replacement of the bearing/seal and the damage of main mill because of the loosened screw.

Simple operation, convenient maintenance

The configuration of the micro powder mill production line is relatively simple, and our engineers can train local operators how to operate and maintain the ultrafine powder grinding mill at the customer’s site.

High capacity, low production energy cost

There are 5 models micro-powder grinding mill in Shanghai MR, and the highest capacity can reach 45 tons per hour. If you compare the same finished product fineness and the same motor power, the capacity of final product of the micro-powder grinding mill is at least 40% higher than that of other mills such as ball mills, raymond mills, etc.

High fineness of final product

You can adjust the classifier of the ultra-fine grinding mill to produce different size of final output, because the classifier is with its own frequency conversion motor. You can use this mill to grind micro powder of non-metallic material from 325 mesh to 3000 mesh. Before delivery from our factory, we can help you set four different discharge fineness modes in advance, which can realize automatic production.

Technical Parameters

Content | Model | ||||

MSF600 | MSF800 | MSF1000 | MSF1250 | MSF1680 | |

Roller qty. (pieces) | 12 | 21 | 28 | 32 | 44 |

Diameter of ring(mm) | φ600 | φ800 | φ 1000 | φ1250 | φ1680 |

Main shaft speed (rpm) | 250-280 | 230-240 | 180-200 | 135-155 | 120-130 |

Max.feeding size (mm) | 20 | 20 | 20 | 20 | 25 |

Final size(mesh) | 325-2500 | 325-2500 | 325-2500 | 325-2000 | 325-2000 |

Capacity (tph) | 0.2-3 | 0.5-4.5 | 1-8.5 | 2.5-14 | 5-25 |

Dimension(m) | 11.5*3.5*5.2 | 13*3*5.8 | 18*4.6*8.6 | 14*9*10.25 | 16*5*11 |

Main mill (kw) | 45 | 75 | 132 | 200 | 315 |

Classifier(kw) | 15 | 18.5 | 30 | 75 | 132 |

Blower(kw) | 37 | 45 | 75 | 132 | 200-220 |

Hammer crusher Motor(kw) | PC300×400 PC400×600 | PC400×600 | PC600×800 | PC600×800 | PC600×800 |

11/18.5 | 18.5 | 45 | 45 | 45 | |

Bucket elevator Motor(kw) | TH200×8.2m TH200×6.04m | TH200×9.79m | TH300×11.05m | TH300×13.55m | TH300*16.31m |

3 | 3 | 4 | 5.5 | 7.5 | |

Belt feeder Motor(kw) | 300×60 ×1000mm | 300×60 ×1800mm | 300×60 ×1800mm | 400×80 ×2000mm | 400×80 ×2800mm |

1.1 | 1.5 | 1.5 | 1.5 | 2.2 | |

Pulse dust collector | DMC96 | DMC120 | LDMC35-8 | LDMC64-9 | LDMC64-9 (2sets) |

DMC160 | |||||

Discharge screw conveyor Motor(kw) | / | LS219-4.5 | LS245-6.2 | LS315-10.34 | LS315-10.34 (2sets) |

LS219-3 | |||||

/ | 3/3 | 4 | 7.5 | 7.5*2 | |

Air compressor Motor (kw) | KSH150D | KSH240D | LGY5-8 | LG6.2/8 | LG10/8 |

11 | 15 | 30 | 37 | 55 | |

Packaging and Shipping

When we send MSF micro-powder grinding mill abroad, we will always use containers for sea transportation. In our factory, we will make test of the main mill, after the approval of our quality control department, we will do anti-rust painting and surface painting before sending the grinding mills.