High Capacity Ball Mill Machine

The ball mill is the key equipment for grinding the material which has already been crushed.

Introduction of High Capacity Ball Mill Machine

High capacity ball mill machine is an efficient machinery for powder making. The high capacity ball mill machine is mainly used to the ore mineral processing equipment, ceramics, chemical and cement industry etc. There are two type of ball mills, the dry ball mill and the wet ball mill.

Application

High capacity ball mill machine is used in mineral ore grinding, like copper ore, gold ore, silver ore, zinc, etc. In recent years, the bearing transmission energy saving ball mill are newly developed, which can save 25-30% energy. Its’ main parts are slowly rotated cylinder, with grinding media inside.

Main Structure

|

① Cylinder

② Slate ③ Feeder ④ Feed screw ⑤ Bearing cap ⑥ Bearing seat ⑦ Roller ⑧ Bracket ⑨ Board |

⑩ Drive seat

⑪ Bridge bearing seat ⑫ Small Gear ⑬ Reducer ⑭ Coupling ⑮ Motor ⑯ Big gear ⑰ Large liner |

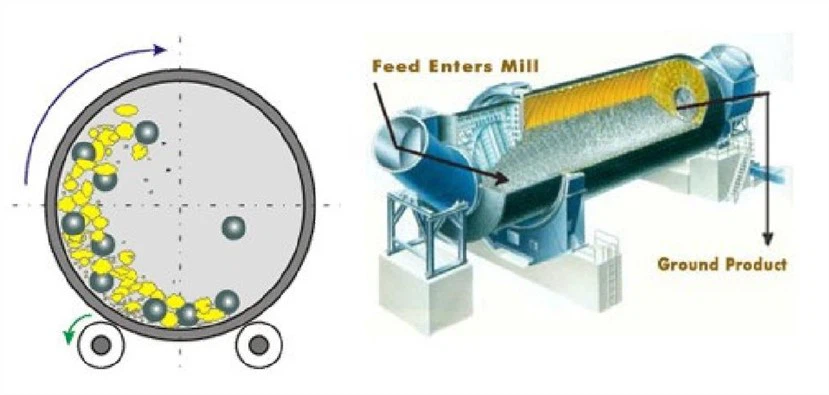

Working Principle

The main body of the ball mill is a revolving cylinder, both ends are equipped with end covers with hollow shafts, the hollow shafts are supported by the main bearings, and the whole mill rotates under the drive of the transmission device. Due to the action of inertial centrifugal force, the grinding body is attached to the lining surface of the inner wall of the mill and rotates together with it. After being brought to a certain height, it falls freely by gravity. The grinding body has a cyclic movement of rising and falling in the rotating mill, resulting in sliding and rolling, resulting in the grinding action between the grinding body, the lining plate and the material to be ground to make the material fine. In order to protect the cylinder from the direct impact of the ball and the sliding friction of the steel ball and the material, the inner wall of the cylinder is also equipped with a lining plate.

Technical Parameters

Model | Power (kW) | Thickness (mm) | Ball load (t) | Weight (t) |

φ900*1800 | 18.5 | 10 | 1.5 | 4.6 |

φ900*3000 | 22 | 10 | 2.7 | 5.6 |

φ1200*2400 | 30 | 12 | 3 | 12 |

φ1200*3000 | 37 | 12 | 3.5 | 12.8 |

φ1200*4500 | 55 | 12 | 5 | 13.8 |

φ1500*3000 | 75 | 16 | 7.5 | 15.6 |

φ1500*4500 | 110 | 16 | 7.5 | 21 |

φ1500*5700 | 130 | 16 | 12 | 25 |

φ1830*3000 | 130 | 18 | 11 | 28 |

φ1830*4500 | 155 | 18 | 15 | 32 |

φ1830*6400 | 210 | 18 | 21 | 34 |

φ1830*7000 | 245 | 18 | 23 | 36 |

φ2100*3000 | 210 | 20 | 19 | 43 |

φ2100*4500 | 245 | 20 | 24 | 46 |

φ2100*7000 | 280 | 20 | 26 | 50 |

φ2200*6500 | 380 | 22 | 35 | 52.8 |

φ2200*7000 | 380 | 22 | 35 | 54 |

φ2200*7500 | 380 | 22 | 35 | 56 |

φ2400*3000 | 245 | 24 | 27 | 60 |

φ2400*4500 | 320 | 24 | 30 | 65 |

φ2400*7000 | 475 | 24 | 54 | 71 |

φ2700*3600 | 400 | 25 | 39 | 83 |

φ2700*4000 | 400 | 25 | 40 | 85 |

φ2700*4500 | 430 | 25 | 48 | 89 |

φ2700*6000 | 630 | 25 | 53 | 93 |

φ3200*3600 | 560 | 30 | 52 | 120 |

φ3200*4500 | 800 | 30 | 65 | 125 |

φ3200*5400 | 800 | 30 | 81.6 | 130 |

φ3000*11000 | 1250 | 30 | 95~100 | 155 |

φ3600*4000 | 800 | 35 | 75 | 185 |