Iron Ore Ball Mill

Iron ore is the core raw material of the steel industry, and its crushing and grinding process directly affects the efficiency and economic benefits of mineral processing. As a key grinding equipment, ball mill energy consumption、 performance, maintenance costs have attracted much attention.

Introduction

MR high-efficiency iron ore ball mill is designed for the most demanding mining conditions in South America. Suitable for wet or dry grinding, it features manganese steel liners and forged grinding balls to provide finer particle size, lower energy consumption and longer service life.

Ideal for magnetite, hematite and pellet feed production, our Grinding ball mill are equipped with intelligent automation systems to achieve optimal performance in mines in Chile, Brazil and Peru.

Application

Ball mill for iron ore uses a wet grinding process to efficiently crush raw materials such as magnetite and hematite to 200-400 mesh, meeting the fineness requirements of subsequent magnetic separation and flotation processes.

Large-scale mines in South America generally use large Ball mill machine above Φ3.2m, equipped with wear-resistant high-chromium steel balls and rubber liners to meet the grinding needs of high-hardness ores.

In recent years, the application of energy-saving bearing-driven Mining ball mill in Chile’s copper-iron mixed mining areas has significantly reduced energy consumption by 30%.

Some Brazilian mines also use automated control systems to adjust the speed and feed rate in real time, so that the processing capacity of a single device is increased to 80-120 tons/hour, greatly improving the recovery rate of iron ore resources.

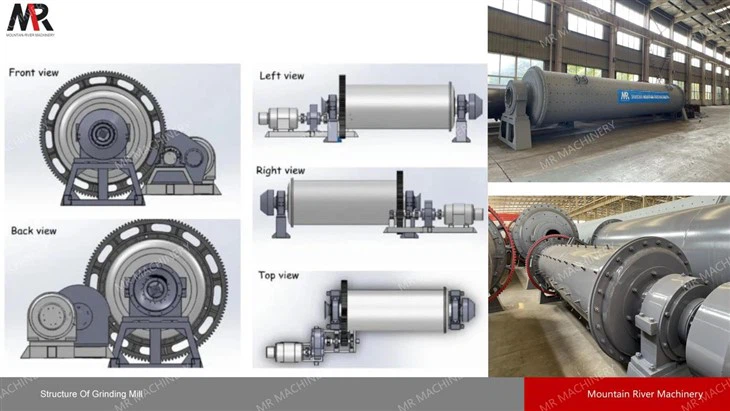

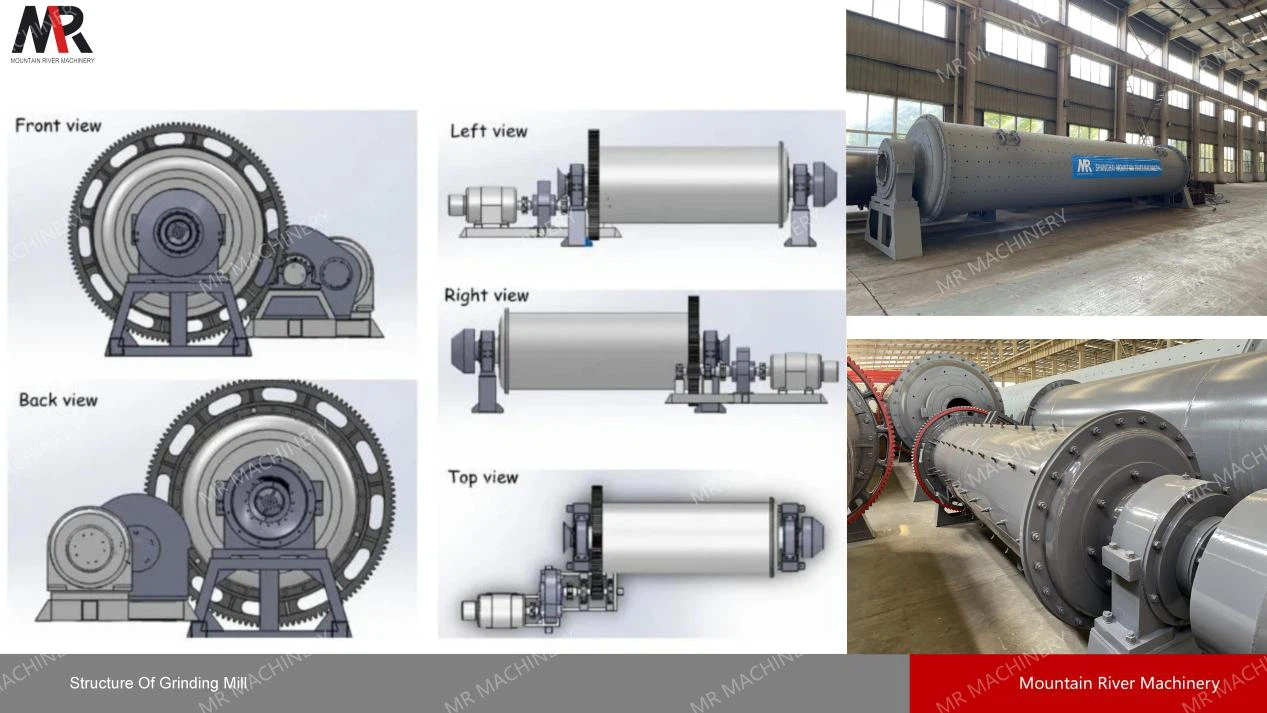

Working Principle

Large iron ore particles continuously enter the rotating cylinder of the ball mill through the feed end. When the cylinder speed reaches the critical maximum point, the grinding medium steel balls of different diameters break the large iron ore particles through the impact force generated by free fall.

The steel balls will also produce a grinding effect when sliding at the bottom of the cylinder, further refining the material into the final powder particles. Ball mill liners inside the cylinder not only protects the cylinder, but also increases the height of the steel balls.

By adjusting the speed, steel ball ratio and grinding time, the particle size of the discharge can also be accurately controlled.

Technical Parameters

Model | Power (kW) | Thickness (mm) | Ball load (t) | Weight (t) |

φ900*1800 | 18.5 | 10 | 1.5 | 4.6 |

φ900*3000 | 22 | 10 | 2.7 | 5.6 |

φ1200*2400 | 30 | 12 | 3 | 12 |

φ1200*3000 | 37 | 12 | 3.5 | 12.8 |

φ1200*4500 | 55 | 12 | 5 | 13.8 |

φ1500*3000 | 75 | 16 | 7.5 | 15.6 |

φ1500*4500 | 110 | 16 | 7.5 | 21 |

φ1500*5700 | 130 | 16 | 12 | 25 |

φ1830*3000 | 130 | 18 | 11 | 28 |

φ1830*4500 | 155 | 18 | 15 | 32 |

φ1830*6400 | 210 | 18 | 21 | 34 |

φ1830*7000 | 245 | 18 | 23 | 36 |

φ2100*3000 | 210 | 20 | 19 | 43 |

φ2100*4500 | 245 | 20 | 24 | 46 |

φ2100*7000 | 280 | 20 | 26 | 50 |

φ2200*6500 | 380 | 22 | 35 | 52.8 |

φ2200*7000 | 380 | 22 | 35 | 54 |

φ2200*7500 | 380 | 22 | 35 | 56 |

φ2400*3000 | 245 | 24 | 27 | 60 |

φ2400*4500 | 320 | 24 | 30 | 65 |

φ2400*7000 | 475 | 24 | 54 | 71 |

φ2700*3600 | 400 | 25 | 39 | 83 |

φ2700*4000 | 400 | 25 | 40 | 85 |

φ2700*4500 | 430 | 25 | 48 | 89 |

φ2700*6000 | 630 | 25 | 53 | 93 |

φ3200*3600 | 560 | 30 | 52 | 120 |

φ3200*4500 | 800 | 30 | 65 | 125 |

φ3200*5400 | 800 | 30 | 81.6 | 130 |

φ3000*11000 | 1250 | 30 | 95~100 | 155 |

φ3600*4000 | 800 | 35 | 75 | 185 |