Ball Mill For Lead-Zinc Ore Grinding

Introduction of Ball Mill for Lead-Zinc Ore Grinding

Lead-zinc ore is an important metal ore. It mainly contains lead and zinc ores. Mining and processing lead-zinc ore requires a series of processes such as crushing, grinding and refining. When grinding lead-zinc ore, ball mill is the most common grinding equipment.

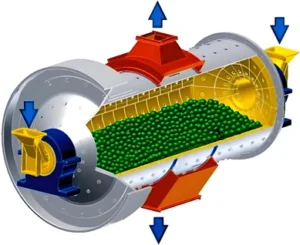

Working Principle of Ball Mill

The working process of ball mill uses the principle of impact. When the ball falls from near the top of the cylinder to the bottom, the grinding medium and the material are impacted, and the size of the material is reduced by the impact, turning it from particles to powder.

The ball mill consists of a hollow cylinder rotating around its own axis, which is cylindrical. The axis of the ball mill cylinder can be horizontal or at a small angle to the horizontal. It is loaded with balls inside, which are the grinding media. The composition of the balls is heavy, and can be steel (chrome steel), stainless steel, rubber or ceramic. The inner surface of the cylindrical cylinder is usually equipped with a wear-resistant liner, which is usually made of manganese steel or rubber.

According to your needs, our engineers will calculate the weight and size of the balls to be installed, and the weight and size of the liner. In the treatment of lead-zinc ore, since the mineral is relatively hard, the grinding medium is generally steel balls, and the liner is also made of manganese steel.

Relationship between the Fineness of the Finished Product Ground by a Ball Mill One-Stage Mill and Two-Stage Mill

There are many ways to grind lead-zinc ore with a ball mill, such as: one-stage grinding, multi-stage grinding and tailings re-grinding. The selection of the number of grinding stages for lead-zinc ore is mainly determined by the co-existence relationship between lead and zinc and other gangue minerals, as well as the embedded particle size of the ore.

The purpose of grinding is to dissociate lead and zinc from gangue mineral monomers. Since different lead-zinc ores have different compositions and embedded particle sizes, the particle size that can complete the monomer dissociation is naturally different, and this particle size determines the number of grinding stages. If you want to get a finer particle size after grinding, generally speaking, you need more grinding stages.

Advantages of One-Stage Grinding Process and Two-Stage Grinding Process

When grinding lead-zinc ore with a ball mill, the main advantages of the one-stage grinding process compared with the two-stage grinding process are:

(1) The number of classifiers is relatively small, and you do not need to invest a lot of money to buy many powder selection machines.

(2) There is usually an intermediate product transportation between stages, and multiple series of grinding machines can be placed at the same level to work, so the equipment configuration is simpler, and the operation and adjustment are simpler.

(3) The shutdown of one stage of the lead-zinc ore ball mill or classifier will not affect the work of another grinding stage, and the shutdown loss is small.

(4) Each series can be installed with larger equipment.

Disadvantages of the One-Stage Grinding Process and the Two-Stage Grinding Process

The main disadvantages are:

(1) The feed particle size range of the lead-zinc ore ball mill is very wide, which makes it difficult to load the balls reasonably and the grinding efficiency is low.

(2) The overflow fineness of the classification in the one-stage grinding process is generally less than 60% of the powder finer than 200 mesh, so it is not easy to obtain a finer final product.

(3) The particle size composition of the lead-zinc ore grinding product is not very good, which is not conducive to selection.