Mini Small Jaw Crusher

Mini small jaw crusher is suitable for secondary crushing and medium crushing of various materials whose compressive strength does not exceed 320 MPa.

Introduction of Mini Small Jaw Crusher

Mini small jaw crusher is a mechanical equipment designed for small and medium-sized crushing operations. Its core structure includes a frame, a movable jaw, a fixed jaw and an eccentric shaft. The eccentric shaft is driven by a motor to drive the movable jaw to reciprocate, forming an extrusion effect with the fixed jaw to crush the material into the required particle size. This equipment is suitable for mining, construction, metallurgy and other fields. It can efficiently process raw materials with higher hardness. Its compact design and flexible adjustment function make it perform well in small production lines and can meet diverse crushing needs. At the same time, the equipment has stable operation and simple maintenance, making it an ideal choice for small and medium-sized crushing operations.

Application

Mini small jaw crusher can efficiently process a variety of hard and medium hard materials, including natural ores such as granite, quartz, iron ore, basalt, limestone, diabase, etc., as well as recycled materials such as concrete blocks, bricks and tiles, waste asphalt, reinforced concrete, etc. in the construction field. In addition, it can also be used to crush brittle materials such as glass, ceramics, slag, coal gangue, gypsum, etc., and can even process some light metal waste and industrial waste, with a wide range of applications.

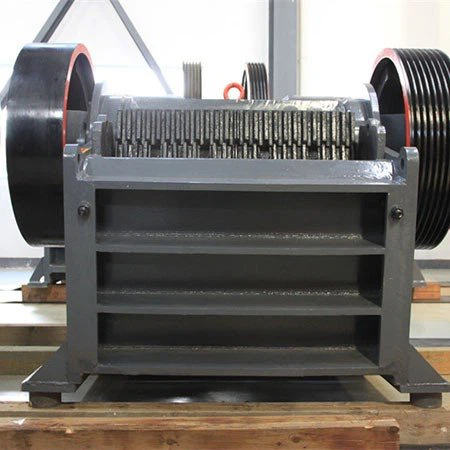

Main Structure

1.Flywheel | 2. Upper Guard Plate | 3. Fix Jaw Plate | 4. Frame |

5. Lower Guard Plate | 6. Tension Rod | 7. Eccentric Shaft | 8. Moveable Jaw |

9. Swing Jaw Plate | 10. Adjustment Seat | 11. Toggle Plate | 12. Spring |

Technical Parameters

Model. Inlet size (mm) Max. Feeding Size(mm) Output Size Range (mm) Capacity (t/h) Power(kw) Weight(t) PE150×250 150*250 130 10-40 0.96-4.8 5.5 0.81 PE250×400 250×400 220 20-80 5-21 15 2.8 PE250×750 250×750 220 25-60 8-22 22 4.9 PE250×1000 250×1000 220 20-40 15-50 30 6.06 PE250×1200 250×1200 220 20-40 20-70 37 6.7 PE300×1300 300×1300 250 20-90 20-85 75 12.5 PE400×600 400×600 350 40-100 15-70 30 6.5 PEW250×1000 250×1000 220 20-40 15-50 30 6.06 PEW250×1200 250×1200 220 20-40 20-70 37 6.7 PEW400×600 400×600 350 40-100 15-70 30 6.5

Model. | Inlet size (mm) | Max. Feeding Size(mm) | Output Size Range (mm) | Capacity (t/h) | Power(kw) | Weight(t) |

PE150×250 | 150*250 | 130 | 10-40 | 0.96-4.8 | 5.5 | 0.81 |

PE250×400 | 250×400 | 220 | 20-80 | 5-21 | 15 | 2.8 |

PE250×750 | 250×750 | 220 | 25-60 | 8-22 | 22 | 4.9 |

PE250×1000 | 250×1000 | 220 | 20-40 | 15-50 | 30 | 6.06 |

PE250×1200 | 250×1200 | 220 | 20-40 | 20-70 | 37 | 6.7 |

PE300×1300 | 300×1300 | 250 | 20-90 | 20-85 | 75 | 12.5 |

PE400×600 | 400×600 | 350 | 40-100 | 15-70 | 30 | 6.5 |

PEW250×1000 | 250×1000 | 220 | 20-40 | 15-50 | 30 | 6.06 |

PEW250×1200 | 250×1200 | 220 | 20-40 | 20-70 | 37 | 6.7 |

PEW400×600 | 400×600 | 350 | 40-100 | 15-70 | 30 | 6.5 |

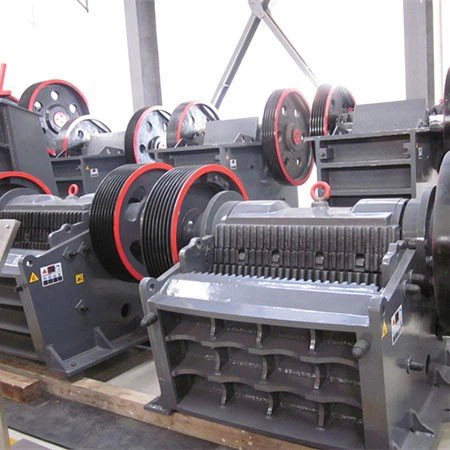

Pictures of Mini Small Jaw Crusher