PE Jaw Crusher

PE jaw crushers is used as primary crushing to crush ores and bulk materials to medium particle size.

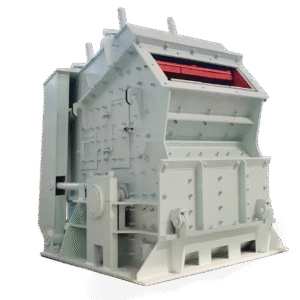

Introduction

The PE jaw crusher is mainly used for primary crushing, efficiently breaking down various ores and bulk materials into medium-sized particles. It plays a crucial role in industries like mining, metallurgy, construction, highways, railways, water conservancy, and chemicals.

Application

PE jaw crusher is widely used in mining, sand and gravel production, cement manufacturing and other fields. It is used in construction sites, stone factories, railway construction and other places. It is suitable for crushing various materials such as granite, basalt, limestone, iron ore, copper ore, etc.

Main Structure

The structure of PE jaw crusher is actually not complicated. It is mainly composed of frame, movable jaw, fixed jaw, eccentric shaft, toggle plate, adjusting device, flywheel, pulley and spring pull rod. The various parts of the machine cooperate with each other, so that the crusher can operate efficiently and stably.

Technical Parameters

Model. | Inlet size (mm) | Max. Feeding Size(mm) | Output Size Range (mm) | Capacity (t/h) | Power(kw) | Weight(t) |

PE150×250 | 150*250 | 130 | 10-40 | 0.96-4.8 | 5.5 | 0.81 |

PE250×400 | 250×400 | 220 | 20-80 | 5-21 | 15 | 2.8 |

PE250×750 | 250×750 | 220 | 25-60 | 8-22 | 22 | 4.9 |

PE250×1000 | 250×1000 | 220 | 20-40 | 15-50 | 30 | 6.06 |

PE250×1200 | 250×1200 | 220 | 20-40 | 20-70 | 37 | 6.7 |

PE300×1300 | 300×1300 | 250 | 20-90 | 20-85 | 75 | 12.5 |

PE400×600 | 400×600 | 350 | 40-100 | 15-70 | 30 | 6.5 |

PE500×750 | 500×750 | 425 | 50-100 | 40-110 | 55 | 10 |

PE600×900 | 600×900 | 500 | 65-160 | 70-120 | 75 | 13.9 |

PE750×1060 | 750×1060 | 630 | 80-140 | 120-260 | 90 | 28 |

PE900×1200 | 900×1200 | 750 | 95-165 | 220-380 | 130 | 46.5 |

PE1000×1200 | 1000×1200 | 850 | 195-265 | 230-380 | 130 | 57 |

PE1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 200 | 100.9 |

Customer Site

Workers are working diligently, carefully installing and fixing the jaw crusher to ensure that the equipment is stable and reliable. After installation, they are debugging and checking whether all components are operating normally.