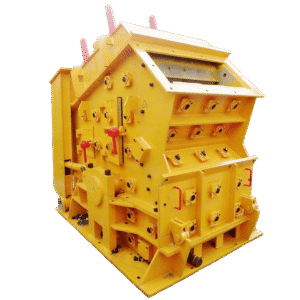

Hydraulic Hammer Crusher

The hydraulic hammer crusher is suitable for secondary crushing and fine crushing of ores whose crushing compressive strength is not higher than 320MPa (MPa).

Introduction

The hydraulic hammer crusher is mainly suitable for crushing various ores with a compressive strength not higher than 320MPa (MPa). It is widely used in industrial and mining enterprises such as metallurgy, mining, chemical industry, cement, construction, refractory materials and ceramics.

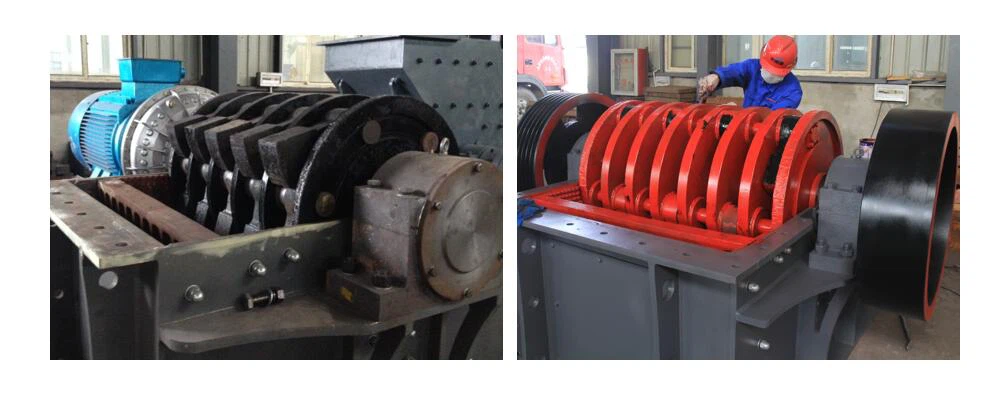

Hydraulic hammer mill is mainly composed of frame, rotor, impact iron bar, grating bar and other components. The frame consists of upper and lower parts, which are welded together after cutting by steel plate, the remaining parts connected into a whole by bolts. There is a high manganese steel liner inside the frame for easy replacement after wear. There are a number of hammer bars regularly distributed on the shaft, which make up the rotor along with the turntable and thru-bar shafts. The shaft is driven by the motor and the V-belt, which promotes the rotor to rotate. The centrifugal force produced when the rotation causes the hammer to stretch. When the large materials enter the crushing cavity, they are crushed by the rotary hammers. high-speed, the crushed products meeting the required size can be discharged from the sieve plate and become the final products, the larger-sized products are returned to the crushed zone for re-crushing, repeatedly hitting with a hammer and an iron bar, until they reach the required size. In order to avoid clogging, the water content of the crushed material generally does not exceed 20%.

(1) High productive capacity and large crushing ratio.

(2) Product with low energy consumption and uniform granularity.

(3) Simple mechanical structure, well knitted and manageable.

(4) Low investment costs and convenient management.

Technical Parameters

Model | Rotor diameter (mm) | Rotor length (mm) | Rotor speed (rpm) | Feeding Size (mm) | Output size (mm) | Capacity (tph) | Dimension (L*W*H) |

PC 4008-75 | 750 | 800 | 800-1000 | <100 | 0-3 | 35-50 | 1800*1650*1800 |

PC 4012-90 | 900 | 1200 | 800-1000 | <100 | 0-3 | 50-70 | 2200*2100*2200 |

PC 4015-132 | 1500 | 1500 | 800-1000 | <100 | 0-3 | 70-100 | 2860*2500*2500 |

Site Photo