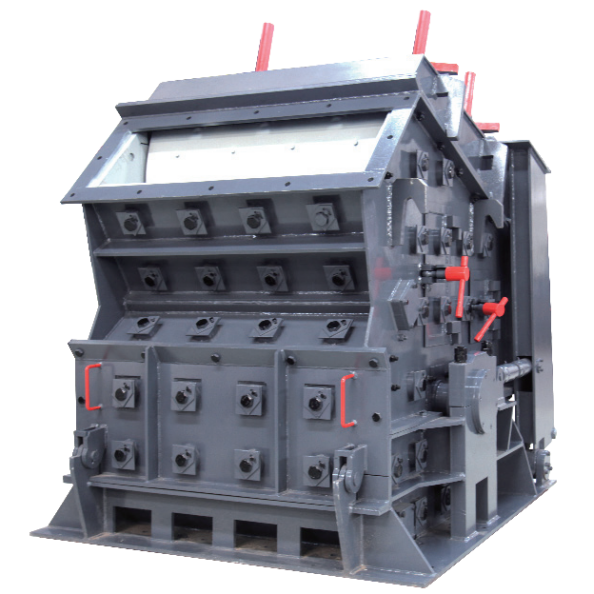

PF Impact Crusher Machine

The PF Series Impact Crusher is a key equipment designed for efficiently crushing medium-hard materials utilizing impact energy. It employs a proven rotor design and a robust, heavy-duty structure.

Introduction

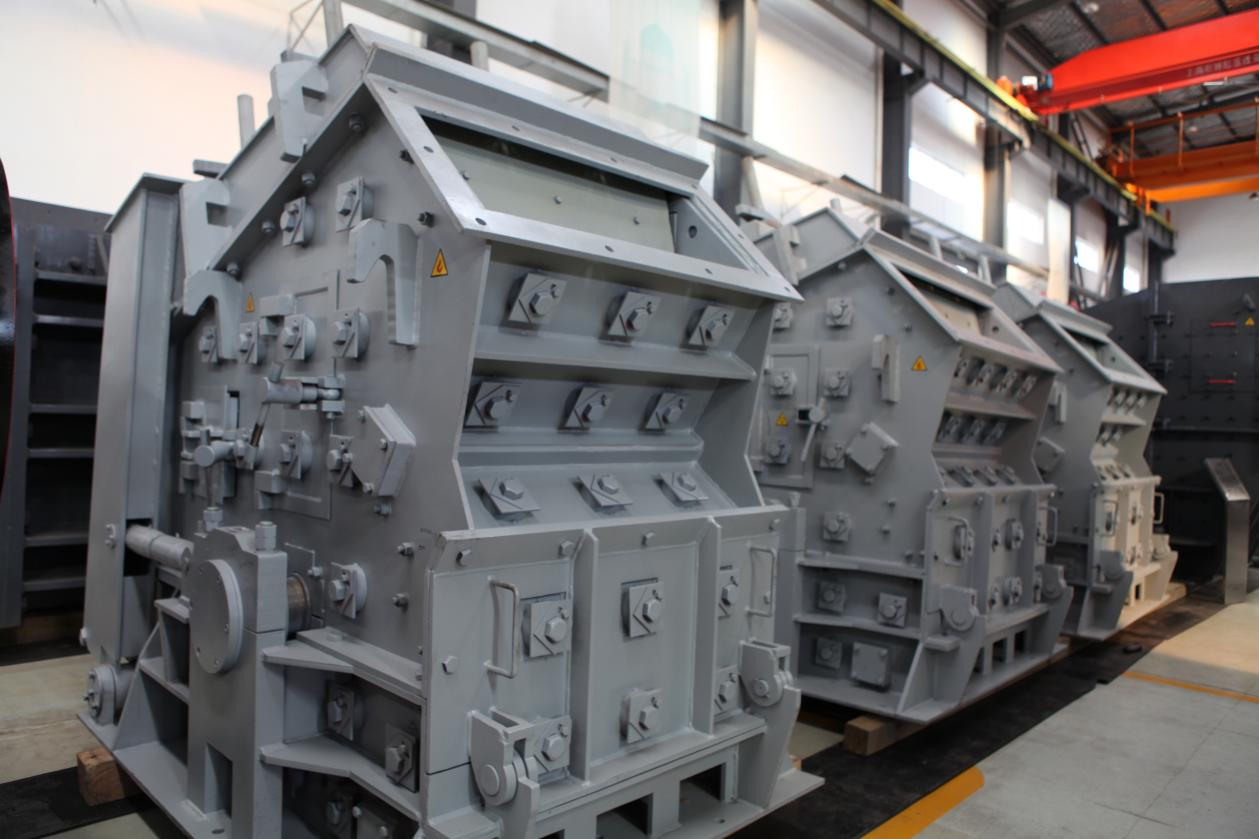

The PF Series Impact Crusher is a key equipment designed for efficiently crushing medium-hard materials utilizing impact energy. It employs a proven rotor design and a robust, heavy-duty structure. Known for its high reduction ratio, excellent particle shape adjustment capability, and low operating costs, it is widely used in secondary or tertiary crushing stages across multiple industries such as mining, building materials, metallurgy, and chemical engineering.

Application

The PF Impact Crusher serves as a core crushing unit in industrial sectors including metallurgy, mining, cement, chemical engineering, refractories, and ceramics. It is also extensively applied in infrastructure projects such as highway construction, water conservancy engineering, construction aggregate production, and manufactured sand processing. Its primary application scope covers materials with medium compressive strength and below, including construction raw materials like limestone, calcite, and gypsum; non-metallic minerals like feldspar, talc, kaolin, and rare earth; and ores such as barite and fluorite.

Technical Parameters

Model | Rotor Specifications (mm) | Inlet Size (mm) | Feed Particle Size (mm) | Capacity (t/h) | Weight (t) |

PF1010 | Φ1050×1000 | 400×1080 | <350 | 50-80 | 11.4 |

PF1210 | Φ1250×1050 | 400×1080 | <350 | 60-120 | 14.2 |

PF1214 | Φ1250×1400 | 400×1430 | <350 | 80-160 | 15.8 |

PF1315 | Φ1300×1500 | 860×1520 | <350 | 120-260 | 19.3 |

Working Principle

The motor drives the rotor shaft of the impact crusher via V-belts. Materials are first crushed by the high-speed impact of the hammers mounted on the rotating rotor and are then thrown against the impact plates for further crushing. Subsequently, the materials rebound from the impact plates back into the action zone of the hammers to be crushed again. This process repeats continuously. Material flows from the feed inlet through the primary crushing zone, then into the secondary crushing chamber, and finally into the tertiary chamber (for three-chamber models). When the crushed material reaches a size smaller than the gap between the hammers and the impact plates, it is discharged from the lower part of the machine as the final product.

Installation Instructions

The impact crusher must be installed on a solid reinforced concrete foundation.

The height, embedment depth, and plan dimensions of the foundation should be specifically designed according to the site’s geological conditions. Refer to the accompanying foundation drawing for equipment installation dimensions.

Sufficient space must be reserved beneath the foundation to accommodate the installation of conveying equipment and facilitate routine maintenance.

To reduce operational vibration, it is recommended to install a vibration damping material layer between the equipment and the foundation. Alternatively, the equipment can also be mounted on a dedicated steel structure support frame.

Note: The position of the transmission unit can be adjusted and installed according to actual site layout requirements.