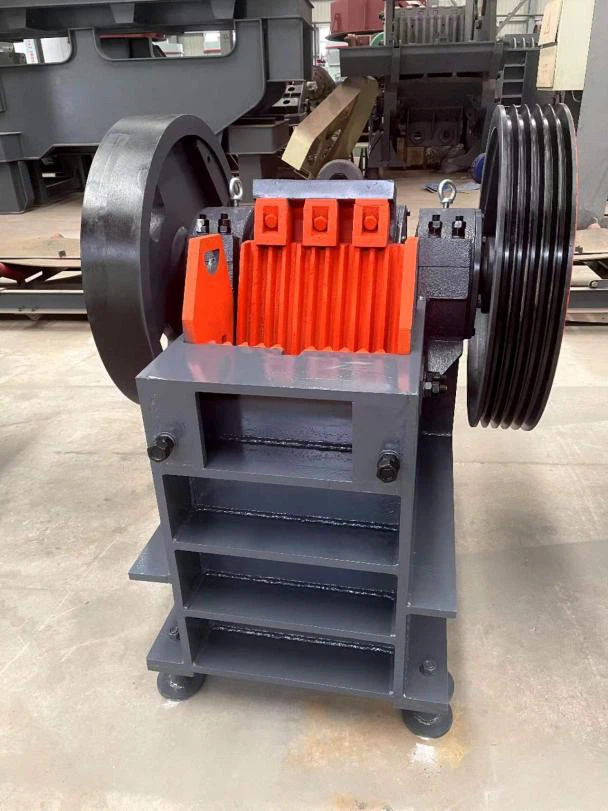

PE Jaw Stone Crusher

Latin America Jaw crusher machine is a mining machinery equipment for coarse crushing of ore, and is often used in mines to break large stones into small stones.

Description

Jaw crusher machine is a mining machinery equipment for coarse crushing of ore. It is commonly found in mines and building materials factories and is the first “tooth” on the production line.

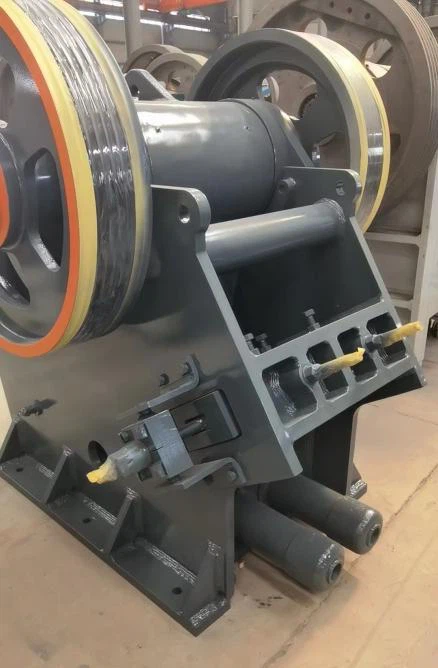

Its core structure consists of two jaw crusher jaw plates: one is fixed and called the fixed jaw, and the other is called the movable jaw, which swings back and forth like a chin.

When the ore is fed into the feed port, the movable jaw plate will repeatedly squeeze and crush the material, “biting” the large stone into small pieces. As a crusher, the jaw rock crusher has amazing equipment power and can handle hard materials such as granite, quartz, basalt, copper ore, iron ore, etc. The general feed size is ≤ 80%-90% of the feed size of the jaw crusher equipment (such as PE600×900 jaw crusher mining Latin America Brazil, the maximum feed size is about 500mm), and the finished product size is controlled by adjusting the jaw plate spacing.

Features

Large Feed Inlet Design

The feed inlet is large and open, so you can directly see the stone crushing process and the operation of the movable jaw and fixed jaw to make adjustments.

Robust and Low-Maintenance Structure

The structure is simple, solid and reliable, the maintenance and operation are simple, not easy to damage, and the jaw crusher mining parts can be replaced by ordinary maintenance workers.

Versatile Material Processing

It can crush a variety of materials with different hardness, including medium-hard materials such as limestone, high-hardness materials such as iron ore, and construction waste such as concrete blocks.

Adjustable Discharge Opening

The size of the discharge port is adjustable. Turning the screw can change the discharge port to control the material discharge particle size.

Note:

1. Be careful to avoid mixing in non-breakable impurities such as steel bars, and the material should not be too wet, otherwise it will cause blockage

2.The liner needs to be replaced regularly according to the actual operation and usage on site

Technical Parameter

Model. | Inlet size (mm) | Max. Feeding Size(mm) | Output Size Range (mm) | Capacity (t/h) | Power(kw) | Weight(t) |

PE150×250 | 150*250 | 130 | 10-40 | 0.96-4.8 | 5.5 | 0.81 |

PE250×400 | 250×400 | 220 | 20-80 | 5-21 | 15 | 2.8 |

PE250×750 | 250×750 | 220 | 25-60 | 8-22 | 22 | 4.9 |

PE250×1000 | 250×1000 | 220 | 20-40 | 15-50 | 30 | 6.06 |

PE250×1200 | 250×1200 | 220 | 20-40 | 20-70 | 37 | 6.7 |

PE300×1300 | 300×1300 | 250 | 20-90 | 20-85 | 75 | 12.5 |

PE400×600 | 400×600 | 350 | 40-100 | 15-70 | 30 | 6.5 |

PE500×750 | 500×750 | 425 | 50-100 | 40-110 | 55 | 10 |

PE600×900 | 600×900 | 500 | 65-160 | 70-120 | 75 | 13.9 |

PE750×1060 | 750×1060 | 630 | 80-140 | 120-260 | 90 | 28 |

PE900×1200 | 900×1200 | 750 | 95-165 | 220-380 | 130 | 46.5 |

PE1000×1200 | 1000×1200 | 850 | 195-265 | 230-380 | 130 | 57 |

PE1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 200 | 100.9 |

Customer Service

1. We are jaw crusher latin america supplier. We have two branches in Latin America, one agency and one parts warehouse. Our sales staff and engineers are all local people in Latin America and are familiar with the local terrain. For more than ten years, we have cooperated with customers in Latin America, such as Brazil, Bolivia, Peru, Argentina, etc. Therefore, we have the advantage of serving Latin American customers and jaw crusher latin america export in a comprehensive way and providing localized services.

2. We will provide one-on-one sales and answering services to customers. As long as they are our customers, we will provide complete VIP services to solve problems for customers, and there will be real-time follow-up plans for every step of the sales process.

3. Our sales staff and engineers are all “old partners” who have been deeply involved in the field of mining machinery for more than ten years. They know all the equipment we have, from small parts to large working principles, and can explain to customers.