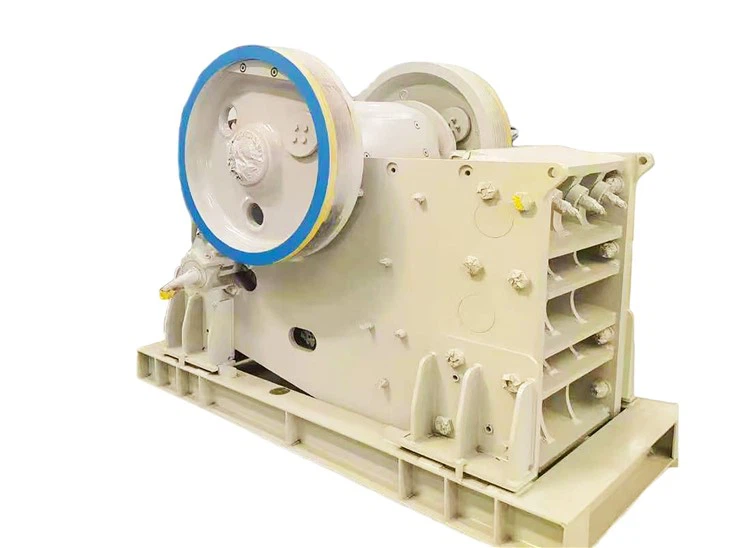

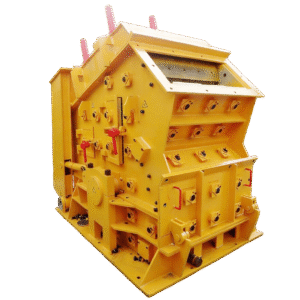

C Series Stone Jaw Crusher

Introduction

C series jaw rock crusher is an efficient and durable primary crushing equipment, widely used in Latin America for the crushing of hard rocks such as iron ore, copper ore, granite and recycling of construction waste. This equipment is upgraded and optimized based on the traditional PE jaw crusher, with higher crushing efficiency, lower energy consumption and more convenient maintenance.

It is particularly suitable for mines, quarries and slag treatment projects in Latin American countries such as Brazil and Bolivia, and has become one of the most popular primary crushing solutions in the region.

Working Priciple

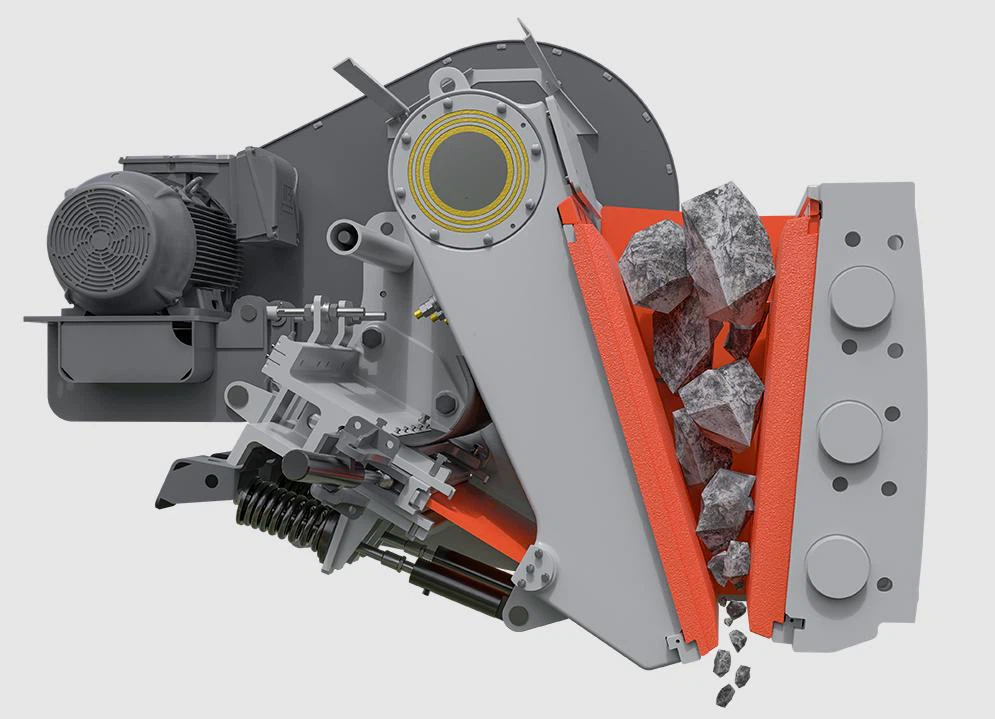

In view of the characteristics of high-hardness ores in Latin America, the C series jaw crusher adopts an advanced V-shaped crushing chamber design, which significantly improves the crushing ratio by optimizing the chamber structure, while effectively reducing the risk of material blockage.

After the material enters the crushing chamber from the feed port, the movable jaw performs a compound motion (front and back + up and down reciprocating motion) driven by the motor. When the movable jaw approaches the fixed jaw, it exerts a strong squeezing effect on the material. With the reciprocating motion of the movable jaw, the material is crushed multiple times, and finally the finished product with the required particle size is evenly discharged from the lower discharge port.

This innovative design not only improves the crushing efficiency, but also ensures the uniformity of the discharge particle size.

Advantage

Integral bearing seat design:

The high-strength one-piece cast steel bearing seat is used to ensure a perfect fit with the crusher frame, greatly improving the assembly accuracy of the main shaft and bearing. This innovative structure significantly enhances the radial load-bearing capacity of the bearing seat, allowing the equipment to operate more smoothly and reliably in harsh environmental areas such as the high-altitude mining areas in Bolivia (such as the Potosi silver mine).

Convenient hydraulic discharge port adjustment system:

The hydraulic double wedge block discharge port adjustment is convenient and safe, and can be adjusted at any time according to needs. One-key online adjustment can be completed within a few minutes, which is convenient and efficient, saving time and effort. The old-fashioned gasket adjustment method is time-consuming and labor-intensive, and the downtime is too long, affecting production.

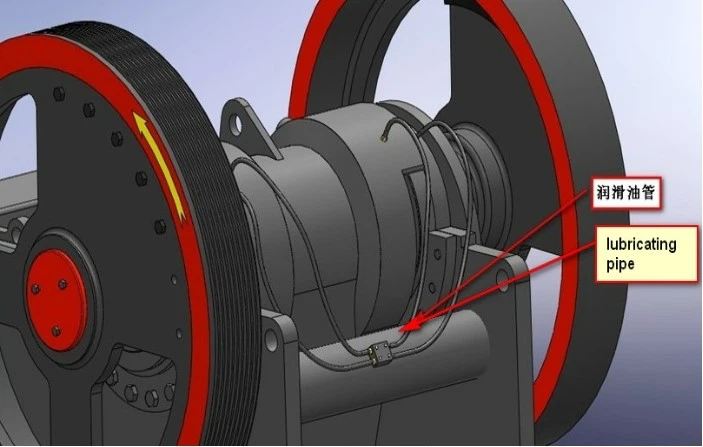

Fully automatic centralized lubrication system:

For extreme environments such as the arid mining areas in Mexico and the Atacama Desert in Chile, it is equipped with an intelligent centralized lubrication device, which effectively solves the problem of high dust, and can automatically complete the lubrication of key parts in a timely and quantitative manner, effectively reducing maintenance time, reducing operating costs, and improving equipment operation rate.

Not only does it simplify the operating process, but it also ensures that each lubrication point of the equipment is always in the best lubrication state, extending the service life of the equipment.

Maintenance

Before starting the C series jaw crusher: check whether the tension of the V-belt is appropriate, ensure that the toggle plate is not worn beyond the limit (if the wear limit is reached, it must be replaced immediately), confirm that the jaw plate bolts are tightened and not loose, verify that the toggle plate protective rubber plate is in the correct position and in good condition, and check whether the tie rod nut is locked to ensure that all key components are in normal condition to ensure safe and efficient operation of the equipment.

Lubrication and maintenance points: To ensure the normal operation of the machine and extend its service life, grease must be added regularly. The amount of grease in the bearing seat should be maintained at 50-70%, and it should be replaced every 3-6 months. When replacing, clean the bearing with gasoline or kerosene and open the oil hole.