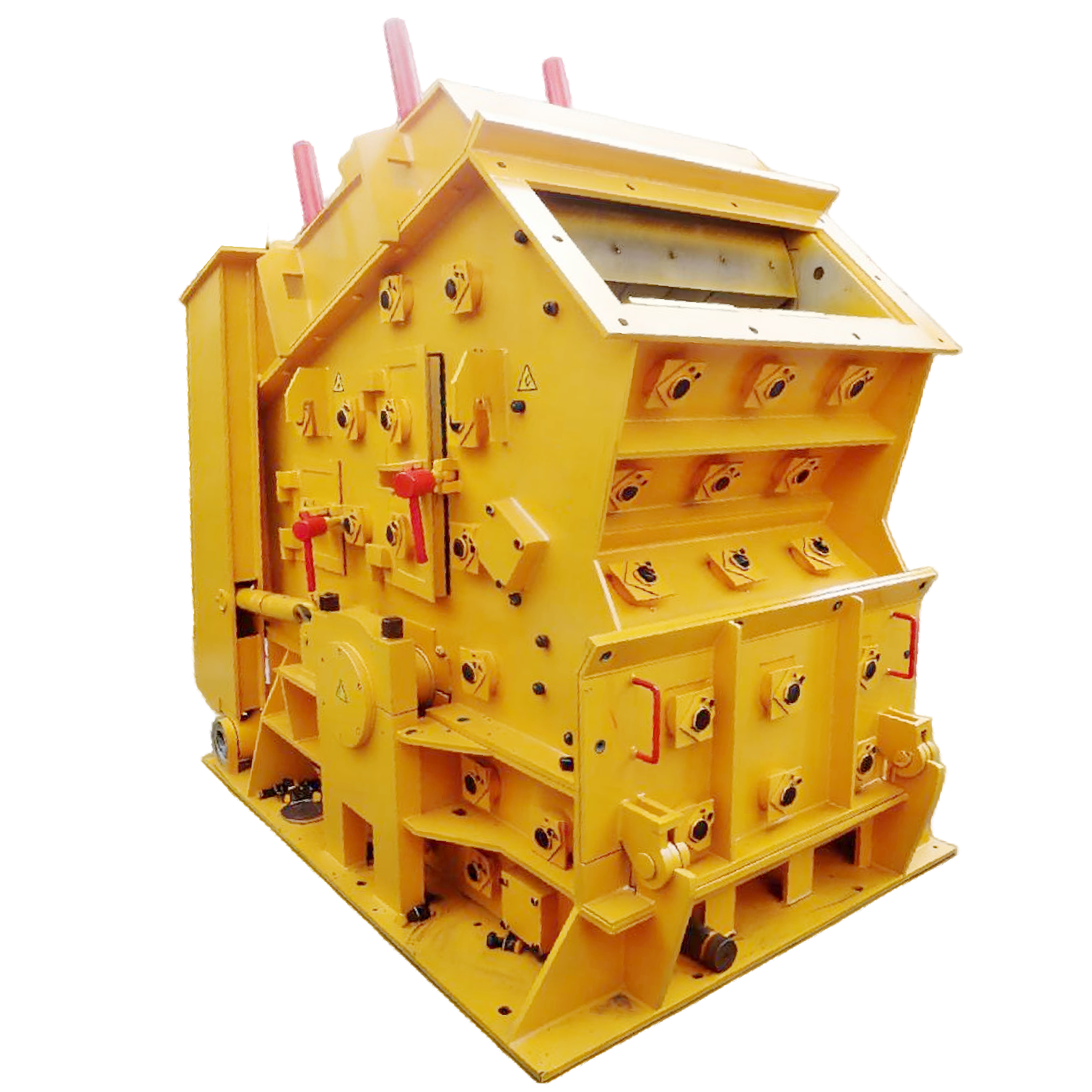

Energy Saving PF Impact Crusher

The PF Impact Crusher serves as a highly efficient medium and fine crushing equipment. Due to its remarkable impact crushing ratio, it can process raw materials with particle sizes up to several hundred millimeters directly into an ideal product below 25 mm in a single pass. Finer outputs can also be easily obtained through adjustment.

Introduction

The PF Impact Crusher serves as a highly efficient medium and fine crushing equipment. Due to its remarkable impact crushing ratio, it can process raw materials with particle sizes up to several hundred millimeters directly into an ideal product below 25 mm in a single pass. Finer outputs can also be easily obtained through adjustment. It is widely applicable to various materials of medium hardness and below, such as limestone, recycled concrete, and coal gangue. With its excellent cubic-shaped end products, the PF Impact Crusher plays a vital role in many key fields including mining, construction aggregate production, transportation infrastructure projects, and the resource utilization of industrial solid waste.

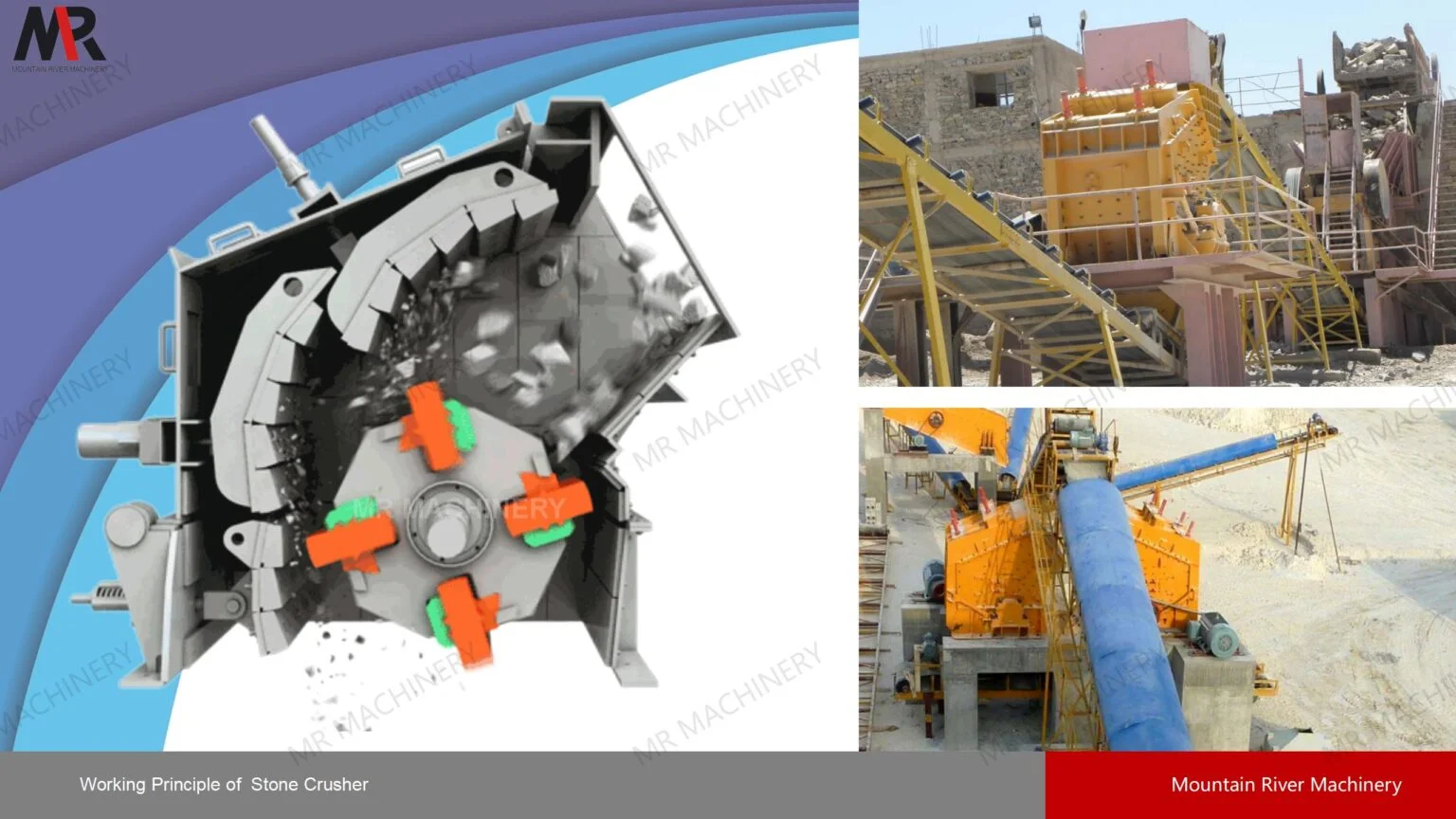

Working Principle

Under the influence of high-speed centrifugal force, the material is thrown directly towards the first-stage impact liner installed on the upper part of the machine. The unique serrated or zigzag surface design of the impact liner promotes the expansion of micro-cracks within the material, causing it to rebound violently. Part of the rebounding material collides violently in mid-air with the subsequent stream of fresh material continuously ejected by the rotor, forming a highly efficient “stone-on-stone” selective crushing mode; the other part is rebounded back to the rotor area, where it is struck again by the hammers and re-accelerated, beginning the next crushing cycle.

Finally, when the particle size of the material is refined to less than the preset discharge gap (i.e., the gap between the rotor and the bottom of the impact plate) under repeated impacts, it is smoothly discharged from the discharge port under gravity, becoming a qualified product that meets the particle size requirements.

Technical Parameters

Model | Rotor Specifications (mm) | Inlet Size (mm) | Feed Particle Size (mm) | Capacity (t/h) | Weight (t) |

PF1010 | Φ1050×1000 | 400×1080 | <350 | 50-80 | 11.4 |

PF1210 | Φ1250×1050 | 400×1080 | <350 | 60-120 | 14.2 |

PF1214 | Φ1250×1400 | 400×1430 | <350 | 80-160 | 15.8 |

PF1315 | Φ1300×1500 | 860×1520 | <350 | 120-260 | 19.3 |

Repair and Maintenance

Regular and standardized maintenance is essential to ensure stable operation, extend service life, and improve production efficiency of the PF Impact Crusher. Below are several key considerations:

Regular Inspection and Timely Replacement of Wear Parts

The hammer plates and impact liners are the main wear parts of the PF Impact Crusher. Their wear condition should be checked periodically. When wear reaches the allowable limit or cracks appear, they must be replaced or repositioned promptly to prevent equipment damage and maintain crushing efficiency and product size consistency.

Ensure Rotor Dynamic Balance and Cleanliness

After replacing hammer plates or following prolonged shutdowns, the rotor must undergo dynamic balancing correction to avoid severe vibration that could damage the bearings. Meanwhile, keep the rotor clean to prevent material buildup, which could affect balance and operation.

Maintain Lubrication System Unobstructed and Oil Clean

Regularly inspect the lubrication condition of key components such as the main shaft bearings. Use the specified type of grease or lubricating oil, and keep the lubrication system sealed and clean. Timely replacement of deteriorated or contaminated lubricating oil is the most effective way to prevent bearing overheating and failure.