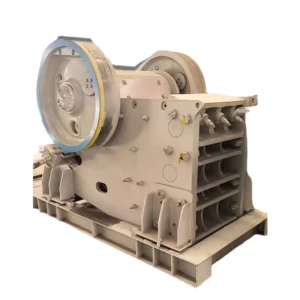

Symons 3ft Cone Crusher

CS series symons 3ft cone crusher is used as secondary crusher to crush different kinds of stones.

Introduction

The spring cone crusher was the first of its kind in the world and remains one of the most widely used crushers in the industry today. The CS Symons cone crusher builds on this traditional design, introducing key improvements that make it more efficient and user-friendly. With a more logical structure and advanced technical features, the CS Symons cone crusher excels in manufacturing quality, ease of installation, smooth operation, and straightforward maintenance. These upgrades make it a reliable and practical choice for modern crushing needs.

Application

The CS Symons 3ft cone crusher is a versatile and efficient machine capable of crushing a wide range of materials, including limestone, marble, granite, river stone, basalt, quartz, iron ore, copper ore, gold ore, and more. It can also handle materials like dolomite, sandstone, shale, gypsum, feldspar, calcite, andesite, diabase, slag, concrete, pebbles, coal, clay, talc, barite, phosphates, manganese ore, nickel ore, and zinc ore.

Main Structure

The main structure of Symons Cone Crusher includes the following parts: first, the crushing chamber, which consists of a moving cone and a fixed cone, is responsible for crushing the material; second, the main shaft and eccentric sleeve, which rotate to drive the moving cone to swing and achieve continuous crushing; then there is a spring or hydraulic system, which is used to adjust the size of the discharge port and overload protection; in addition, there is a lubrication system to ensure that all parts work smoothly during the operation of the equipment. The overall structure is simple and reliable, easy to operate, and suitable for processing ores and rocks with medium hardness or above.

Technical Advantages

(1) Multiple crushing chambers. The CS series Symons spring cone crusher has a specially designed crushing chamber, the user can choose not to provide the crushing chamber, and the crushing efficiency is high.

(2) Dry oil seal dust. The Symons spring cone crusher has a unique dust-sealed structure and is reliable in operation. Sealing extends oil change intervals and spare part life.

3) High output. Compared with other models, the CS series spring cone crusher has a long crushing arm, a long impact distance and a large crushing power, which can effectively crush the materials in the cavity.

(4) The cost of daily operation and maintenance is low, the selection of components is reasonable, and the load on sliding bearings and gears is reduced.

Technical Parameters

Model | Diameter Of Moving Cone (mm) | Cavity | Feed Opening (mm) | Output Range (mm) | Capacity (t/h) | Power (KW) | Weight (t) | |

Closed Side | Open Size | |||||||

CS75B | 900 (3') | Fine | 83 | 102 | 9-22 | 45-91 | 75 | 15 |

Coarse | 159 | 175 | 13-38 | 59-163 | ||||

CS160B | 1295 (4 1/4') | Fine | 109 | 137 | 13-31 | 109-181 | 185 | 27 |

Medium | 188 | 210 | 16-31 | 132-253 | ||||

Coarse | 216 | 241 | 19-51 | 172-349 | ||||

CS240B | 1650 (5 1/2') | Fine | 188 | 209 | 16-38 | 181-327 | 240 | 55 |

Medium | 213 | 241 | 22-51 | 258-417 | ||||

Coarse | 241 | 268 | 25-64 | 299-635 | ||||

CS400B | 2134 (7') | Fine | 253 | 278 | 19-38 | 381-726 | 400 | 110 |

Medium | 303 | 334 | 25-51 | 608-998 | ||||

Coarse | 334 | 369 | 31-64 | 789-1270 | ||||

CS75D | 900 (3') | Fine | 13 | 41 | 3-13 | 27-90 | 75 | 15 |

Medium | 33 | 60 | 3-16 | 27-100 | ||||

Coarse | 51 | 76 | 6-19 | 65-140 | ||||

CS160D | 1295 (4 1/4') | Fine | 29 | 64 | 3-16 | 36-163 | 160 | 27 |

Medium | 54 | 89 | 6-16 | 82-163 | ||||

Coarse | 70 | 105 | 10-25 | 109-227 | ||||

CS240D | 1650 (5 1/2') | Fine | 35 | 70 | 5-13 | 90-209 | 240 | 55 |

Medium | 54 | 89 | 6-19 | 136-281 | ||||

Coarse | 98 | 133 | 10-25 | 190-336 | ||||

CS400D | 2134 (7') | Fine | 51 | 105 | 5-13 | 190-408 | 400 | 110 |

Medium | 95 | 133 | 6-19 | 354-508 | ||||

Coarse | 127 | 178 | 10-25 | 454-599 | ||||