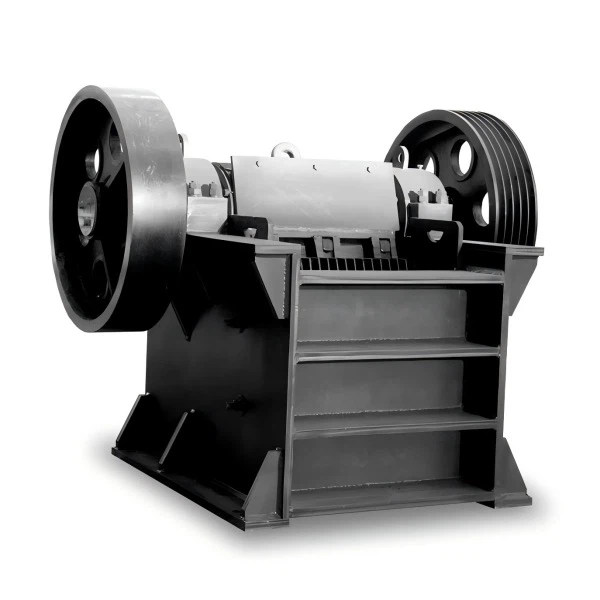

PE Jaw Crusher Machine

PE jaw crusher is an efficient and reliable primary crushing machine that can continuously process various types of ores, such as granite, marble, basalt, limestone, quartz, pebble, iron ore, copper ore, etc.

Working Principle

PE jaw rock crusher is an efficient and reliable primary crusher that can continuously process various types of ores, such as granite, marble, basalt, limestone, quartz, pebble, iron ore, copper ore, etc.

When the mine site needs to produce, the PE stone jaw crusher machine will be the first to start working. At this time, the motor drives the eccentric shaft to rotate through the belt and flywheel, so that the movable jaw can reciprocate according to the predetermined trajectory.

When the movable jaw approaches the fixed jaw, the hard ore material will be squeezed, split and bent between the two jaw crusher jaw plates, and then crushed into material particles of a size that meets customer needs; when the movable jaw is away from the fixed jaw, the crushed material is discharged from the lower part of the crushing chamber under the action of gravity.

As the motor rotates continuously, the movable jaw will continue to crush and discharge the material. This repetitive “squeeze-release” action allows the stationary jaw crusher to continuously process various types of ores, As a jaw crusher manufacturer, we are committed to providing efficient and reliable primary crusher solutions for mining production in Brazil, Bolivia and other Latin American regions.

Technical Parameter

Structure

①The frame is welded with high-strength steel plates to form a solid skeleton of the equipment and ensure overall stability.

②The core crushing components, the movable jaw and the fixed jaw, are cast with special high-manganese steel, which have super wear resistance and impact resistance and are directly involved in material crushing.

③The eccentric shaft is forged with high-quality alloy steel, and is precision machined and heat treated to ensure long-term and stable operation of the equipment.

④The toggle plate is a precisely calculated cast iron part, which is not only a necessary component for force transmission, but also a safety part of the best jaw crusher.

⑤Using gaskets to adjust the outlet size can conveniently and accurately control the particle size of the discharge.

⑥The efficient transmission system realizes power transmission through motors, flywheels and belts.

Application

PE eco jaw crusher widely used in the mining industry in Latin America and around the world, and are suitable for primary crushing of various types of ores:

Cement production: used to crush raw materials such as limestone, clay, shale, etc. to meet the requirements of cement production lines for material particle size.

Aggregate production: Processing hard rocks such as granite and basalt to provide high-quality coarse aggregates for concrete and asphalt mixtures.

Construction waste recycling: In rapidly urbanizing countries such as Brazil and Mexico, PE jaw crushers are used to crush concrete waste, bricks and other construction waste to achieve resource recycling.

Engineering crushing: Suitable for scenes such as road demolition and renovation of old buildings, crushing large pieces of waste building materials into recyclable aggregates.

Hydropower station construction: In countries with rich hydropower resources such as Colombia and Peru, jaw crushers are used to process artificial sand and gravel aggregates to supply dams, channels and other projects.

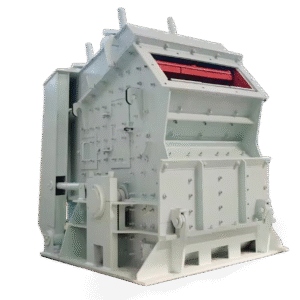

Factory Final Product Photo