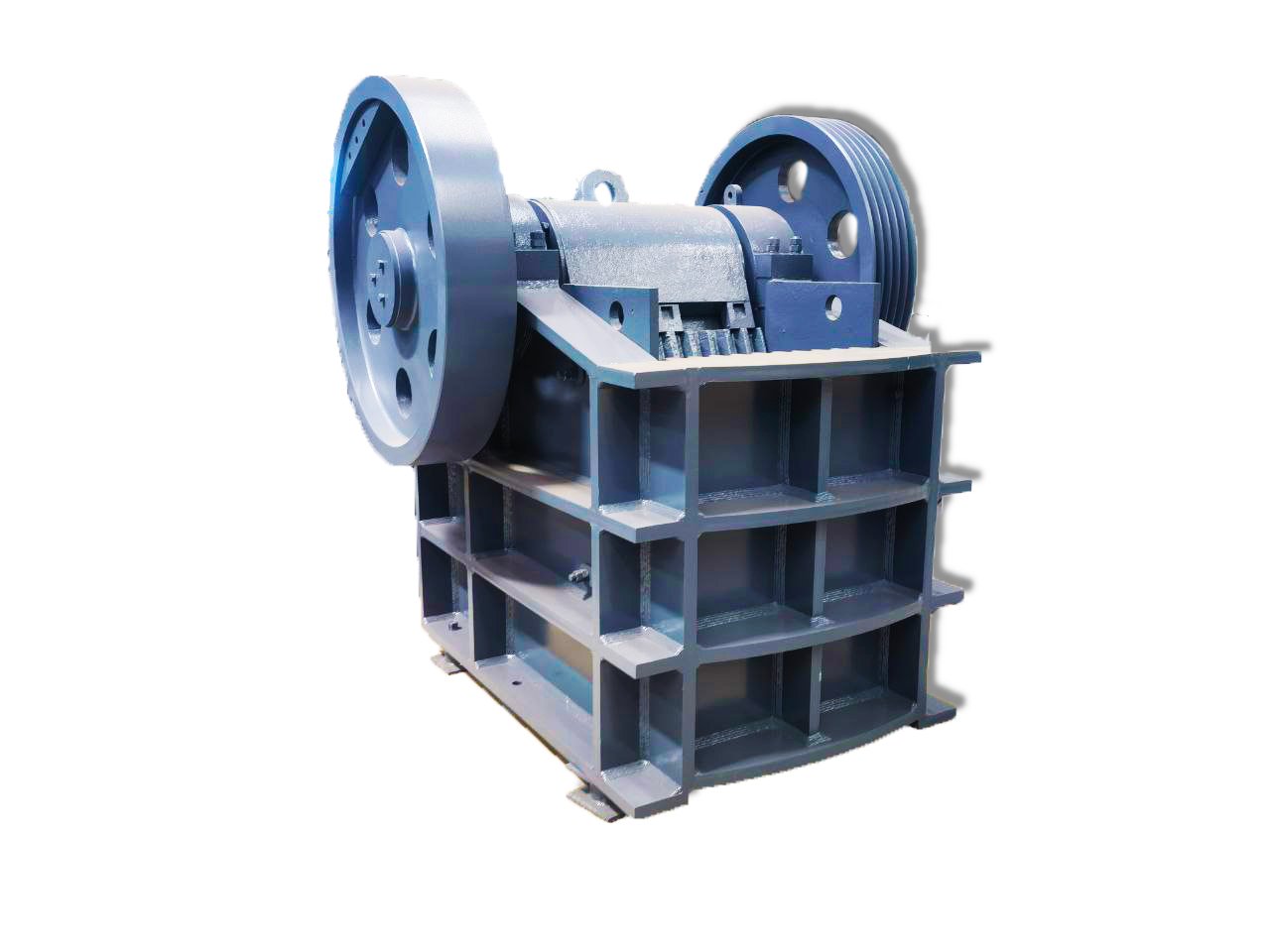

PE Primary Jaw Crusher Machine

At a Latin American mining operation, a PE jaw crusher operates by rotating an eccentric shaft through a belt, driving the movable jaw plate to swing back and forth regularly, causing it to reciprocate along a predetermined trajectory.

Working priciple

At a Latin American mining operation, a PE jaw crusher operates by rotating an eccentric shaft through a belt, driving the movable jaw plate to swing back and forth regularly, causing it to reciprocate along a predetermined trajectory. When the movable jaw approaches the fixed jaw, the hard ore material is squeezed, split, and bent between the two jaw plates, breaking it into smaller pieces. When the movable jaw moves away from the fixed jaw, the crushed ore is discharged from the lower part of the crushing chamber under the action of gravity.

As the motor rotates continuously, the movable jaw crusher periodically crushes and discharges material, enabling batch production. This repetitive “squeeze-release” action enables the equipment to continuously process a variety of ores, providing an efficient and reliable primary crushing solution for mining operations in Latin America, including Brazil and Bolivia.

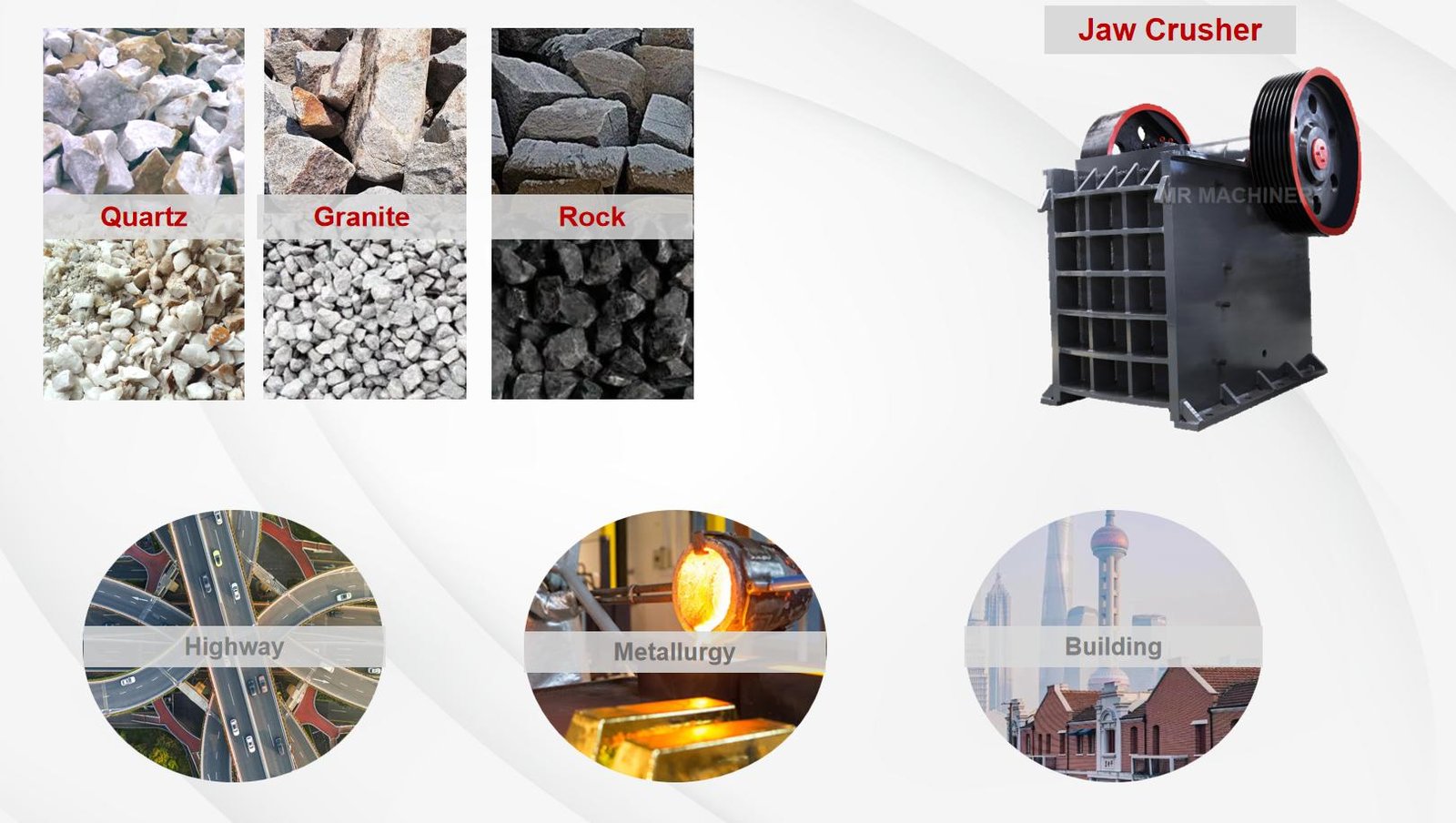

Application

PE jaw crushers are widely used in the mining industry in Latin America and around the world, suitable for primary crushing of various ores:

Aggregate production: Processes hard rocks such as granite and basalt to provide high-quality coarse aggregate for concrete and asphalt mixtures.

Construction waste recycling: In rapidly urbanizing countries such as Brazil and Mexico, PE jaw crushers are used to crush concrete waste, bricks, and other construction waste for resource reuse.

Hydropower station construction: In countries with abundant hydropower resources such as Colombia and Peru, jaw crushers are used to process artificial sand and gravel aggregate for dams, canals, and other projects.

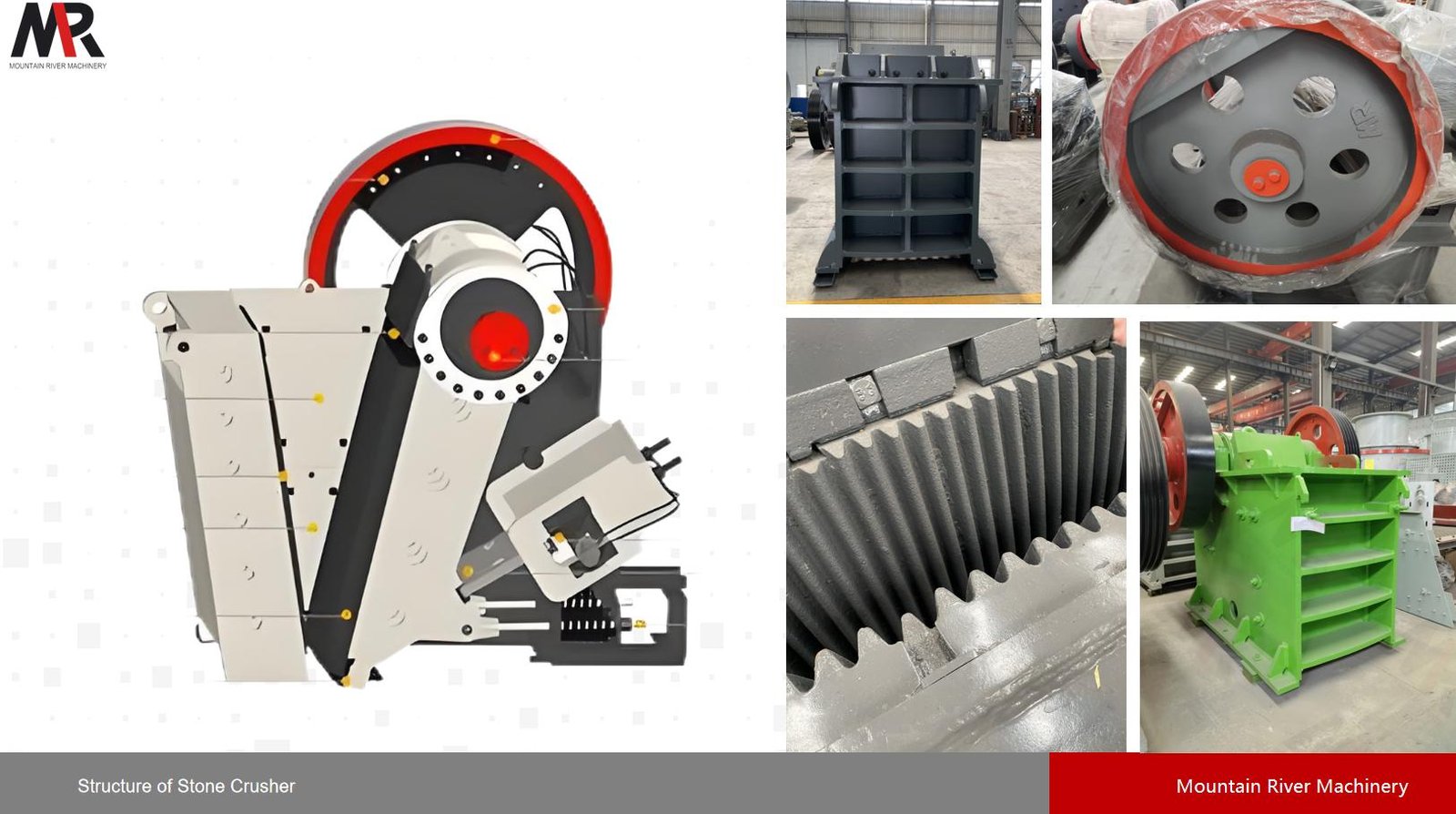

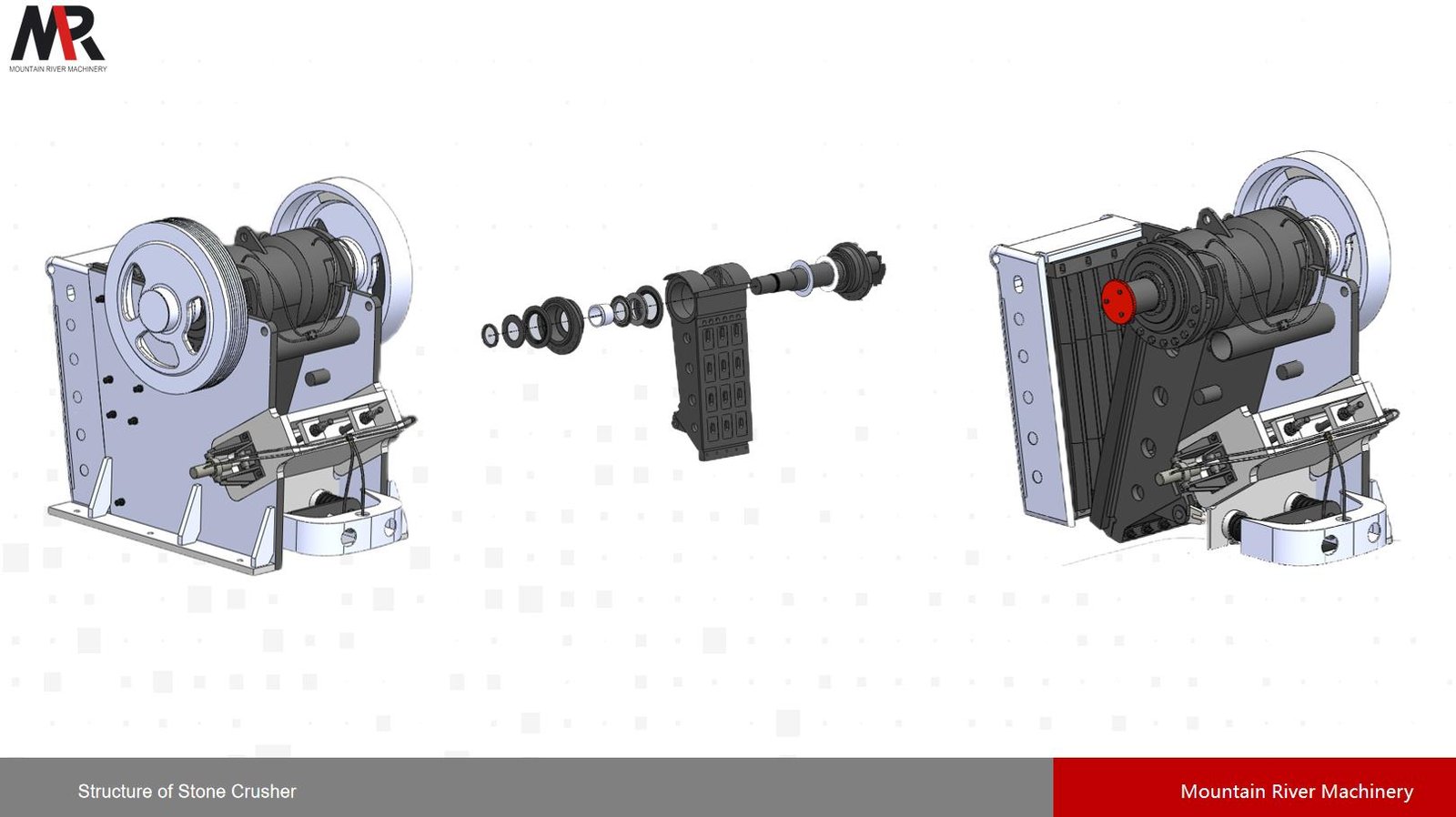

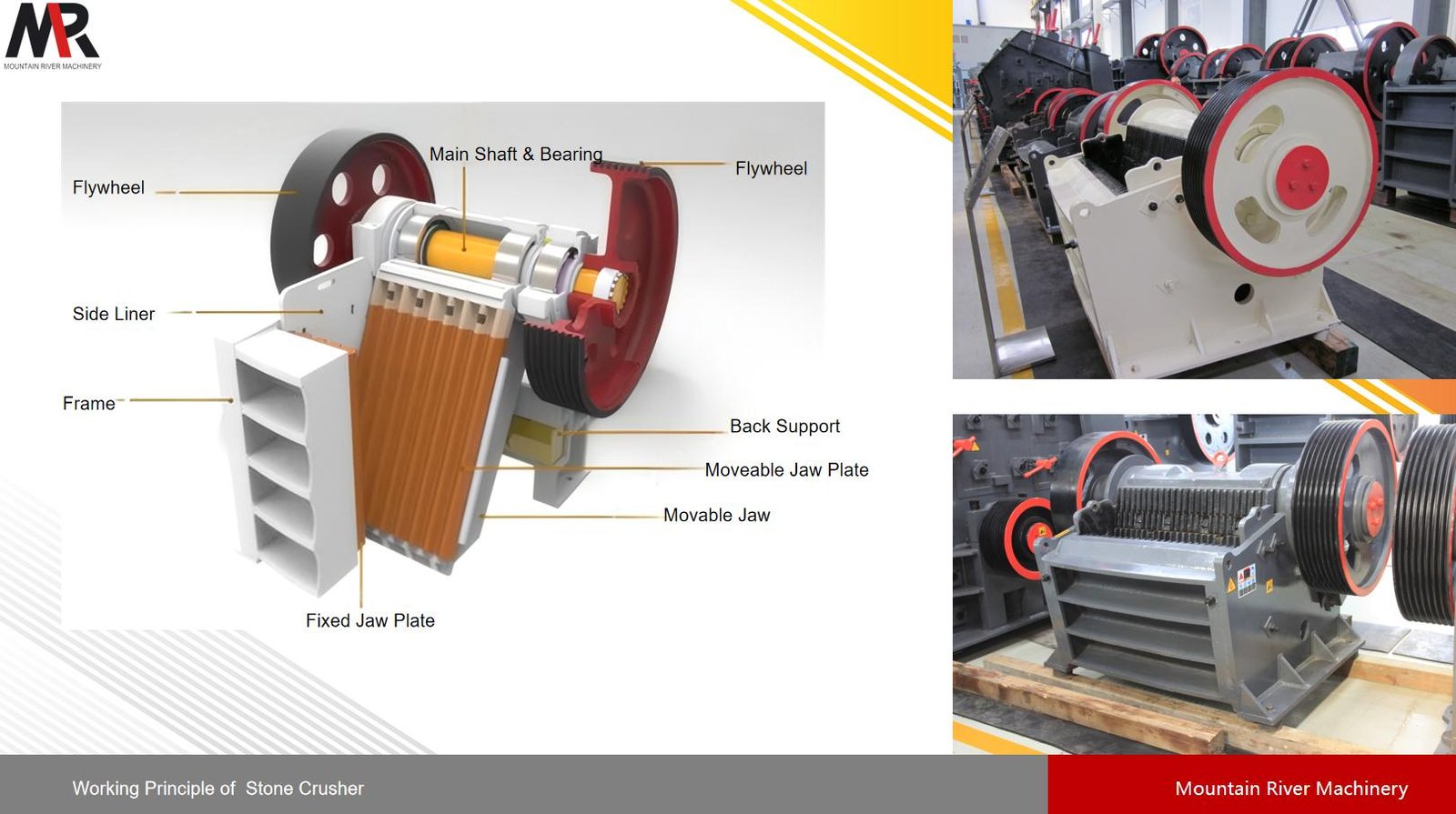

Structure

① The frame is welded from high-strength steel plates, forming a sturdy structure for the equipment and ensuring overall stability.

② The core crushing components, the movable and fixed jaws, are cast from special high-manganese steel, offering exceptional wear and impact resistance and directly participating in material crushing.

③ The eccentric shaft is forged from high-quality alloy steel and undergoes precision machining and heat treatment to ensure long-lasting, stable operation.

④ The intelligent gasket adjustment device precisely controls the output particle size.

⑤ The efficient drive system utilizes a motor, pulleys, and V-belts for power transmission.

⑥ The advanced centralized lubrication system automatically supplies oil to key components, significantly reducing maintenance frequency.

Technical parameter

Model | Feeding Opening (mm) | Max. Feeding Size (mm) | Discharge Port Adjustment Range (mm) | Capacity (t/h) | Power (kw) |

PE150*250 | 150*250 | 125 | 10–40 | 1–3 | 5.5 |

PE200*350 | 200*350 | 180 | 15–50 | 1–6 | 11 |

PE250*400 | 250*400 | 220 | 20–50 | 5–21 | 15 |

PE250*750 | 250*750 | 220 | 25–60 | 8–22 | 22 |

PE250*1000 | 250*1000 | 220 | 20–40 | 15–50 | 30 |

PE250*1200 | 250*1200 | 220 | 20–40 | 20–70 | 37 |

PE300*1300 | 300*1300 | 250 | 20–90 | 20–85 | 75 |

PE400*600 | 400*600 | 350 | 40–100 | 15–70 | 30 |

PE500*750 | 500*750 | 425 | 50–100 | 40–110 | 55 |

PE600*900 | 600*900 | 500 | 65–160 | 70–120 | 75 |

PE750*1060 | 750*1060 | 630 | 80–140 | 120–260 | 90 |

PE900*1200 | 900*1200 | 750 | 95–165 | 220–380 | 130 |

PE1000*1200 | 1000*1200 | 850 | 195–265 | 230–380 | 130 |

PE1200*1500 | 1200*1500 | 1020 | 150–300 | 400–800 | 200 |