C Series Jaw Crusher Equipment

Send InquiryIntroduction

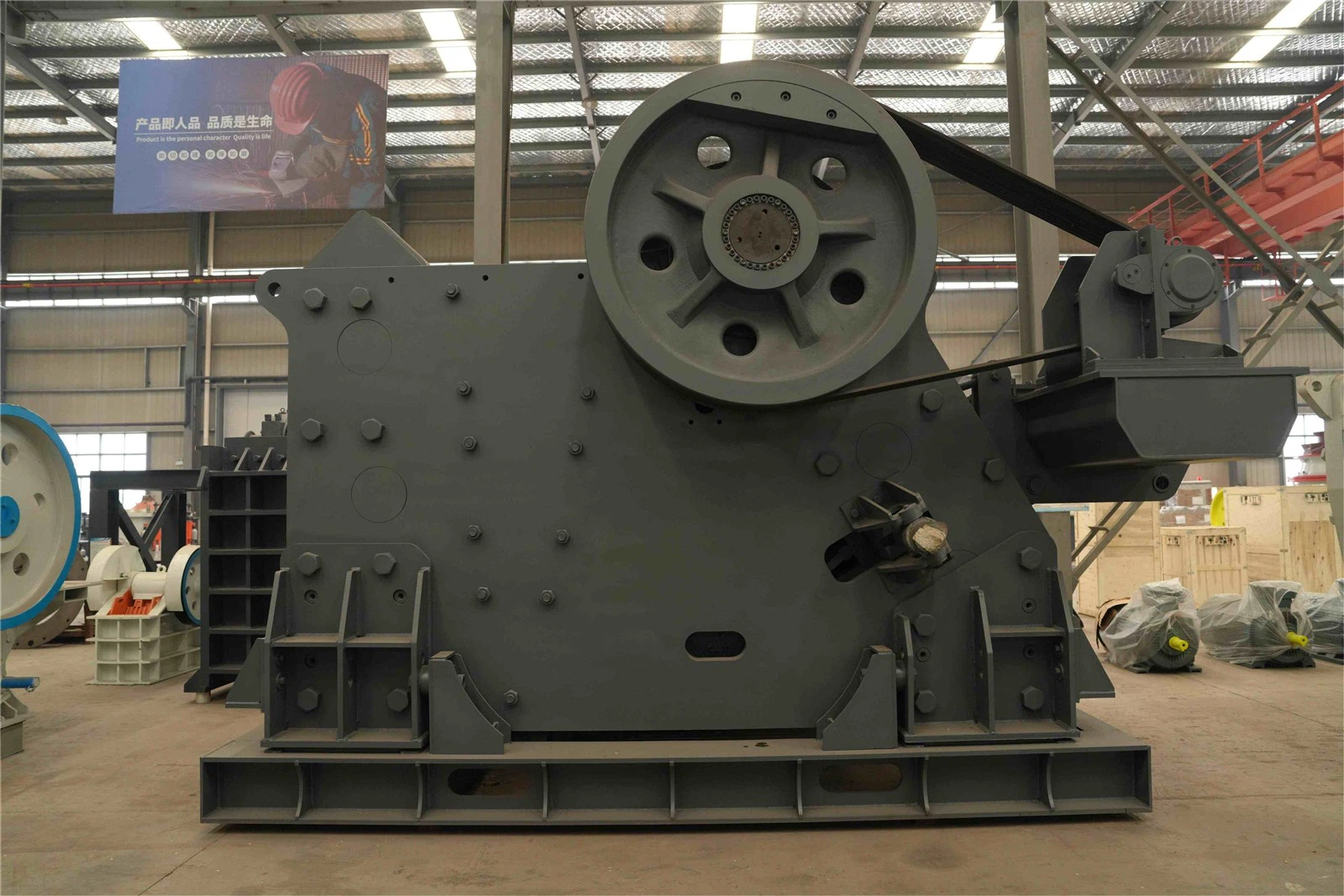

C European version jaw crusher is widely used in mining crushing, construction engineering, mineral processing and other projects. Especially in the production of building aggregates in Latin America, it is more widely used. For example: crushing of Brazilian basalt, crushing of Bolivian river pebbles, crushing of Argentine dolomite, crushing of Mexican barite, crushing of Colombian feldspar, etc.

Technical Parameters

In the stone crushing production lines in South America, the most commonly used C series jaw crusher models are C80, C106, C125, C145, C160, etc.

Model | Feeding Openning (mm) | Max Feeding Size(mm) | Discharge Port Adjustment Range (mm) | Capacity (t/h) | Power (kw) |

C80 | 520*800 | 420 | 60-150 | 80-290 | 75 |

C100 | 760*1000 | 650 | 70-200 | 140-400 | 110 |

C106 | 700*1060 | 600 | 70-200 | 140-420 | 110 |

C110 | 850*1100 | 720 | 80-200 | 160-550 | 160 |

C120 | 870*1200 | 740 | 100-200 | 200-650 | 160 |

C125 | 950*1250 | 800 | 100-250 | 230-760 | 160 |

C145 | 1100*1450 | 920 | 125-275 | 320-950 | 200 |

C160 | 1200*1600 | 1020 | 150-300 | 410-1150 | 250 |

C200 | 1500*2000 | 1200 | 175-300 | 610-1510 | 400 |

CJ6310 | 630*1000 | 580 | 80-180 | 100-195 | 75 |

CJ8711 | 870*1100 | 720 | 85-220 | 130-360 | 110 |

CJ1113 | 1100*1300 | 940 | 120-260 | 260-580 | 160 |

CJ1216 | 1200*1600 | 1050 | 165-320 | 450-800 | 220 |

Advantages

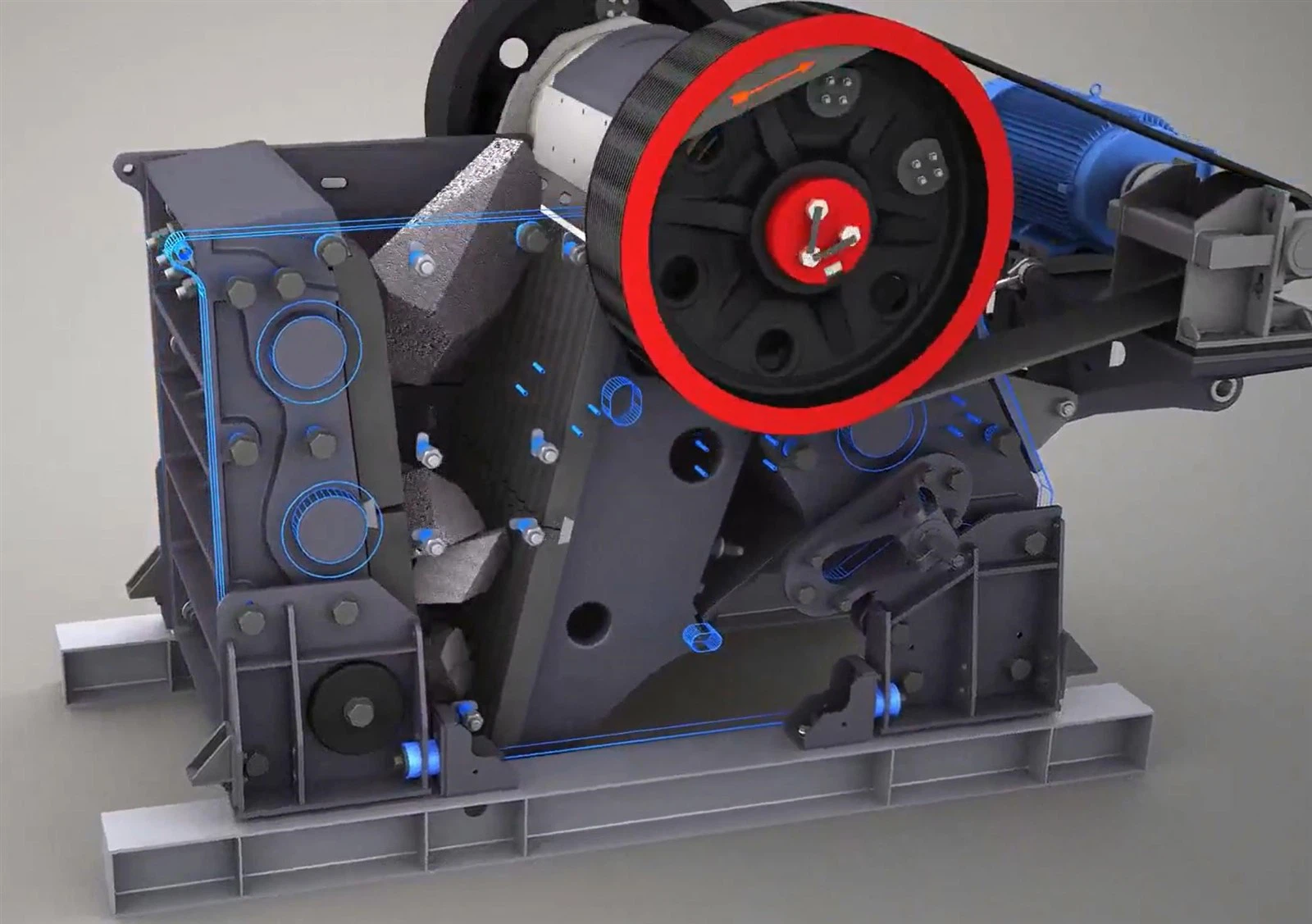

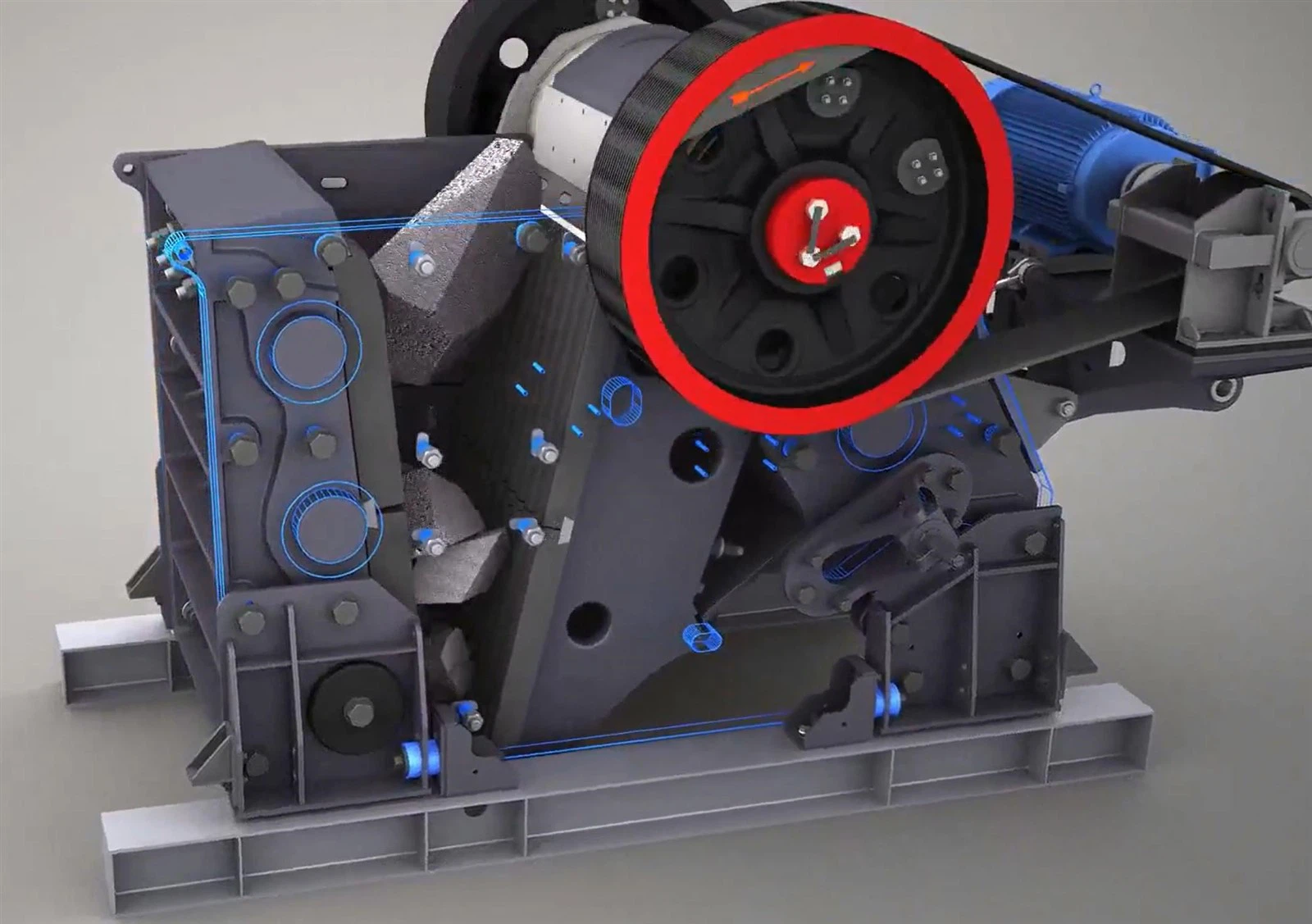

The movable jaw assembly, pulley and flywheel are all made of high-quality steel castings or iron castings. These materials have extraordinary durability and can work longer, which greatly reduces the user’s cost of use.

The use of high-strength forged eccentric shaft and famous brand bearings makes this jaw crusher have high reliability.

The integrated motor base design is adopted, and the motor is directly welded to the equipment, which saves the space required for installing the jaw crusher. The motor base can be moved to adjust the tension of the V-belt, which can extend the service life of the V-belt and greatly reduce the customer’s use cost.

What are the Preparations before Starting the C Series Jaw Crusher?

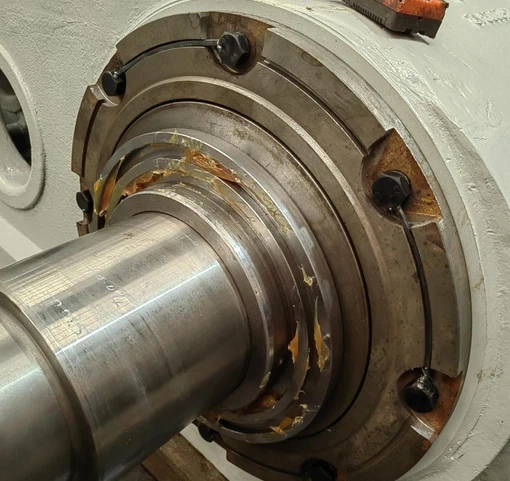

Lubrication check

confirm that the contact surfaces of bearings, elbow plates and gaskets are well lubricated, and add grease in time.

Fastener check

ensure that all screws, bolts and other fasteners are not loose, firm and reliable.

Counterweight check

check whether the counterweight position of the flywheel and the groove wheel is correct (the center hole of the main shaft and the eccentric hole must be 180° straight line).

Belt check

check whether the belt is installed normally, without damage or oil stains, clean it in time when it is dirty, and replace it if it is damaged.

Safety protection check

check whether the protective device is intact and eliminate safety hazards.

Crushing chamber check

clean the residual materials or debris in the crushing chamber to keep the inside clean.