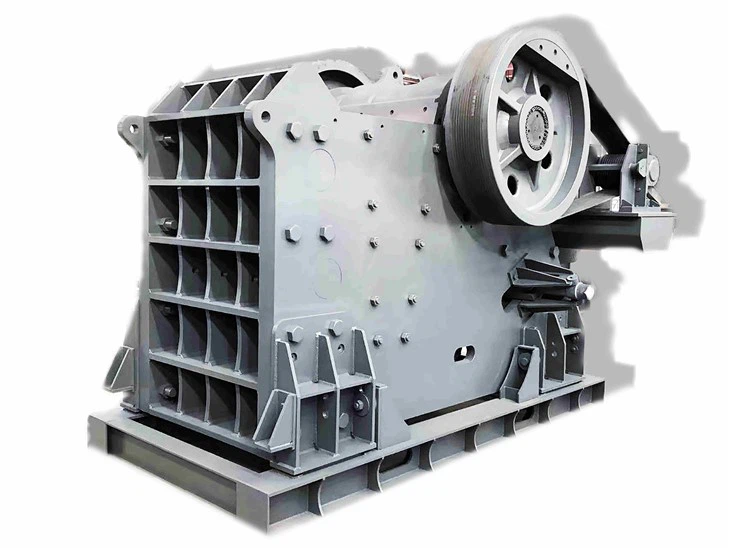

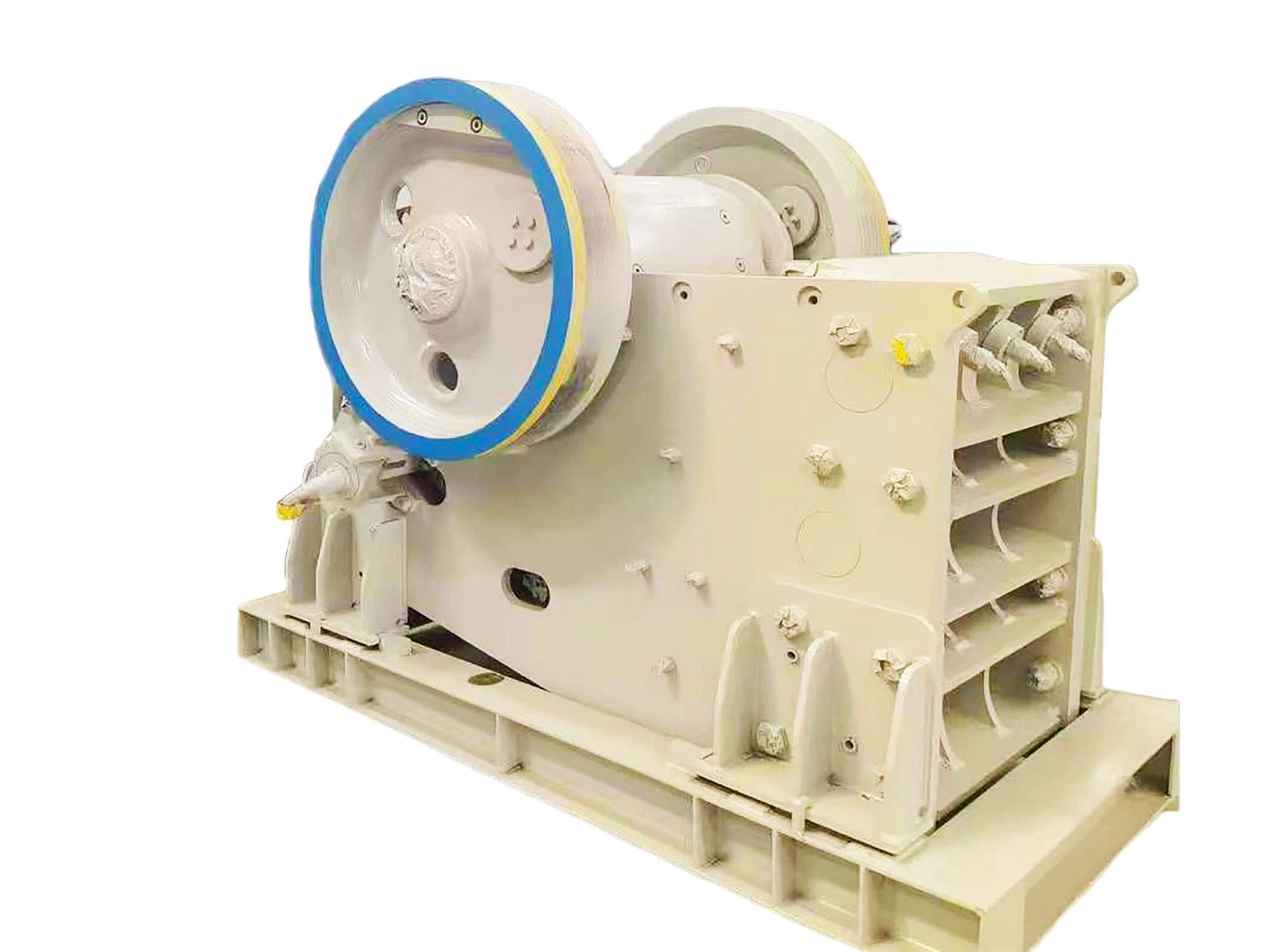

C Series Jaw Crusher Machine

C series jaw crusher is widely used in metal ore beneficiation projects and construction aggregate production projects in Latin America. Compared with traditional PE jaw crusher, it has some unique advantages.

Introduction

C series jaw crusher is widely used in metal ore beneficiation projects and construction aggregate production projects in Latin America. Compared with traditional PE jaw crusher, it has some unique advantages. For example, the body is made of higher quality steel, which enables it to easily crush medium and high hardness materials; and on the basis of retaining the deep V-shaped cavity, engineers have optimized its motion trajectory parameters, so that it can continue to crush during the production process and produce more.

At the same time, the C series jaw crusher adopts an advanced hydraulic wedge adjustment system, which makes the process of adjusting the discharge port more intelligent and convenient, which saves the time of adjusting the discharge port and greatly improves production efficiency. In the same time, it can produce more crushed stones. Therefore, it has become the preferred choice of mine owners in Latin American countries such as Brazil, Argentina, Chile, Bolivia, Mexico and other countries in mining equipment.

Technical Parameters

Model | Feeding Openning (mm) | Max Feeding Size(mm) | Discharge Port Adjustment Range (mm) | Capacity (t/h) | Power (kw) |

C80 | 520*800 | 420 | 60-150 | 80-290 | 75 |

C100 | 760*1000 | 650 | 70-200 | 140-400 | 110 |

C106 | 700*1060 | 600 | 70-200 | 140-420 | 110 |

C110 | 850*1100 | 720 | 80-200 | 160-550 | 160 |

C120 | 870*1200 | 740 | 100-200 | 200-650 | 160 |

C125 | 950*1250 | 800 | 100-250 | 230-760 | 160 |

C145 | 1100*1450 | 920 | 125-275 | 320-950 | 200 |

C160 | 1200*1600 | 1020 | 150-300 | 410-1150 | 250 |

C200 | 1500*2000 | 1200 | 175-300 | 610-1510 | 400 |

CJ6310 | 630*1000 | 580 | 80-180 | 100-195 | 75 |

CJ8711 | 870*1100 | 720 | 85-220 | 130-360 | 110 |

CJ1113 | 1100*1300 | 940 | 120-260 | 260-580 | 160 |

CJ1216 | 1200*1600 | 1050 | 165-320 | 450-800 | 220 |

Composition

The C series jaw crusher mainly consists of a frame part, an eccentric shaft rotating part, a crushing chamber working part, a safety device, a discharge port adjustment device, etc.

1. Frame part: It consists of side plates, front box components, rear box weldments, etc.

2. Eccentric shaft rotating part: It mainly consists of an eccentric shaft, a bearing, a bearing seat, a pulley, etc. It is the main part for transmitting power.

3. Crushing chamber working part: It mainly consists of a fixed jaw plate, a movable jaw plate, a side lining plate, a guard plate, etc. It is an important working part of the C series jaw crusher for crushing materials.

4. Safety device: It consists of a toggle plate, a toggle plate seat, a spring, a spring pull rod, etc. The toggle plate is a part that acts as a safety device for the crusher under abnormal conditions.

5. Hydraulic wedge adjustment device: This device is used to adjust the size of the discharge port and control the particle size of the discharge material.

Important Accessories

Fixed jaw plate

+

movable jaw plate

The fixed jaw and movable jaw are made of high-quality manganese steel. They are one of the key accessories for the C series jaw crusher to perform well.They need to be regularly inspected and replaced according to actual usage.

Toggle plate

Toggle plate not only supports the C series jaw crusher to maintain a stable state during the crushing process, but also is one of the safety devices of the crusher.

If metal material enters the jaw crusher but cannot be crushed, the toggle plate will break to protect the crusher and ensure the safety of the operation. Therefore, it is necessary to frequently observe the toggle plate and replace it in time.

Side guard plate

The side guard plate of the C series jaw crusher is made of high-quality steel and is installed between the fixed jaw and the movable jaw.

It is not only a key structure for the normal operation of the crusher, but also protects the crusher frame. In various projects, it is necessary to regularly check and maintain the side guard plate to ensure the normal operation and work efficiency of the crusher.