MSF Ultra Fine Powder Grinding Machine

MR’s highly efficient and durable ultrafine grinding equipment from China is rapidly becoming a favorite in the South American mining industry due to its excellent cost-effectiveness.

Introduction

MR’s highly efficient and durable ultrafine grinding equipment from China is rapidly becoming a favorite in the South American mining industry due to its excellent cost-effectiveness. This equipment efficiently processes various ores into high-value-added fine powders with a mesh size of 325-2500, significantly increasing the value of mineral resources. South American regions like Brazil, Paraguay, and Argentina possess some of the world’s largest reserves of non-metallic minerals such as barite, kaolin, quartz, and limestone, providing a broad market for the application of micro-powder grinding.

The micro-powder grinding machine is a highly efficient and environmentally friendly grinding machine. It is a next-generation grinding machine developed through numerous technological advancements based on the traditional Raymond mill. Its primary purpose is to meet market demand for finer particle sizes, higher yields, and more environmentally friendly production.

Working Principle

After being crushed, the material is conveyed by an elevator to the main machine, where it is crushed between the grinding rollers and the grinding ring. The crushed powder is lifted by the fan and passed through an analyzer for classification. Fine powder that meets the required fineness is collected in a cyclone collector, while unqualified coarse powder is returned to the grinding chamber for re-grinding, forming a closed-loop system.

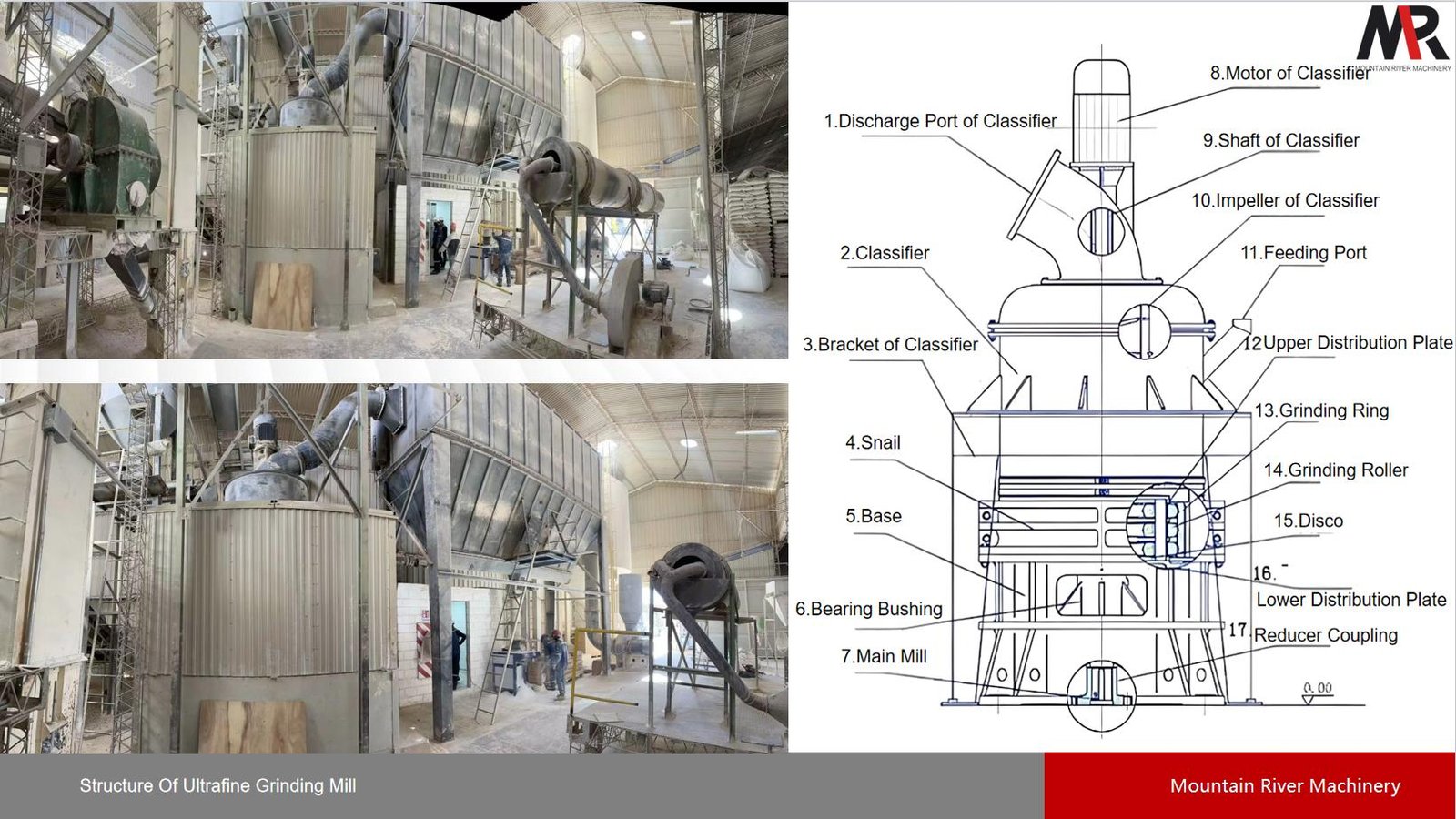

Main Structure

The micro-powder mill boasts a sophisticated and complex structure, primarily consisting of a main unit, feeding system, crushing system, grading system, collection system, and supporting electronic control system. The core of the main unit includes a grinding roller assembly, grinding discs, and a pressure device. Material pulverization is achieved through the rolling action of multiple layers of grinding rollers on a rotating grinding ring. A high-efficiency turbine classifier, independently located above the main unit, precisely controls the fineness of the finished product by adjusting the speed, ensuring a concentrated particle distribution. The pulverized powder is conveyed by airflow to a pulse dust collector for gas-solid separation, achieving efficient and environmentally friendly collection. The entire system operates under negative pressure to effectively prevent dust spillage. Equipped with an intelligent electronic control cabinet, it enables automated control of the entire feeding, grinding, and grading process, ensuring stable operation and consistent product quality.

Technical parameter

Content | Model | ||||

MSF600 | MSF800 | MSF1000 | MSF1250 | MSF1680 | |

Roller qty. | 12 pcs | 21 pcs | 28 pcs | 32pcs | 44pcs |

Diameter of ring | Φ600 mm | Φ800 mm | Φ1000mm | Φ1250mm | Φ1680 |

Main unit speed | 250-280rpm | 230-240rpm | 180-200rpm | 135-155rpm | 120-130rpm |

Max. feeding size | 20mm | 10mm | 20 mm | 20mm | 25mm |

Final size | 325-2500mesh | 325-2500mesh | 325~2500 mesh | 325~2000 mesh | 325~1500 mesh |

Capacity | 0.2~3tph | 0.5~4.5tph | 1~8.5tph | 2.5-14tph | 5~25tph |

Dimension | 11.5 x 3.5 x 5.2m | 13 x 3 x 5.8m | 18 x 4.6 x 8.6m | 14 x 9 x 10.25m | 16 x 5 x 11m |

Main unit | 45KW | 75KW/2 x 37KW | 132KW | 185KW | 280/315KW |

Classifier | 15KW | 18.5KW | 30KW | 4 x 15KW | 5 x 18.5 |

Blower | 37KW | 45KW | 75KW | 110KW | 2 x 90KW |

Hammer crusher | PC300 x 400 | PC400 x 600 | PC400 x 600 | PC600 x 800 | PC600 x 800 |

PC400 x 600 | PC600 x 800 | ||||

11KW/18.5KW | 18.5KW | 18.5KW/45KW | 45KW | 45KW | |

Bucket elevator | TH200 x 8.2m | TH200 x 9.79m | TH300 x 11.05m | TH300 x 13.55m | TH300*16.31m |

TH200 x 6.04m | |||||

3KW | 3KW | 4KW | 5.5KW | 7.5KW | |

Belt feeder | 300 x 60 x 1M | 300 x 60 x 1.8M | 300 x 60 x 1.8M | 400 x 80 x 2M | 400 x 80 x 2.8M |

1.1KW | 1.5KW | 1.5KW | 1.5KW | 2.2KW | |

Dust collector | DMC96 | DMC120/160 | LDMC250 | LDMC450 | 2 x LDMC400 |

Air compressor | LG3.2/8 | KSH150D | KSH300D | LG6.2/8 | LG10/8 |

11KW | 11KW | 22KW | 37KW | 55KW | |