Intelligent Raymond Mill

MGW Intelligent Grinder: How to keep production capacity stable?MGW Intelligent Ginding Mill is a vertical grinding equipment commonly used in mines. It has the advantages of small footprint, high efficiency and low power consumption.

Introduction

MGW Intelligent Grinding Mill is a vertical grinding equipment commonly used in mines. It has the advantages of small footprint, high efficiency and low power consumption. Compared with other grinding mills, the passing rate of the MGW Raymond mill can reach 100%, and it is considered to be a grinding machine with small one-time investment.

Composition

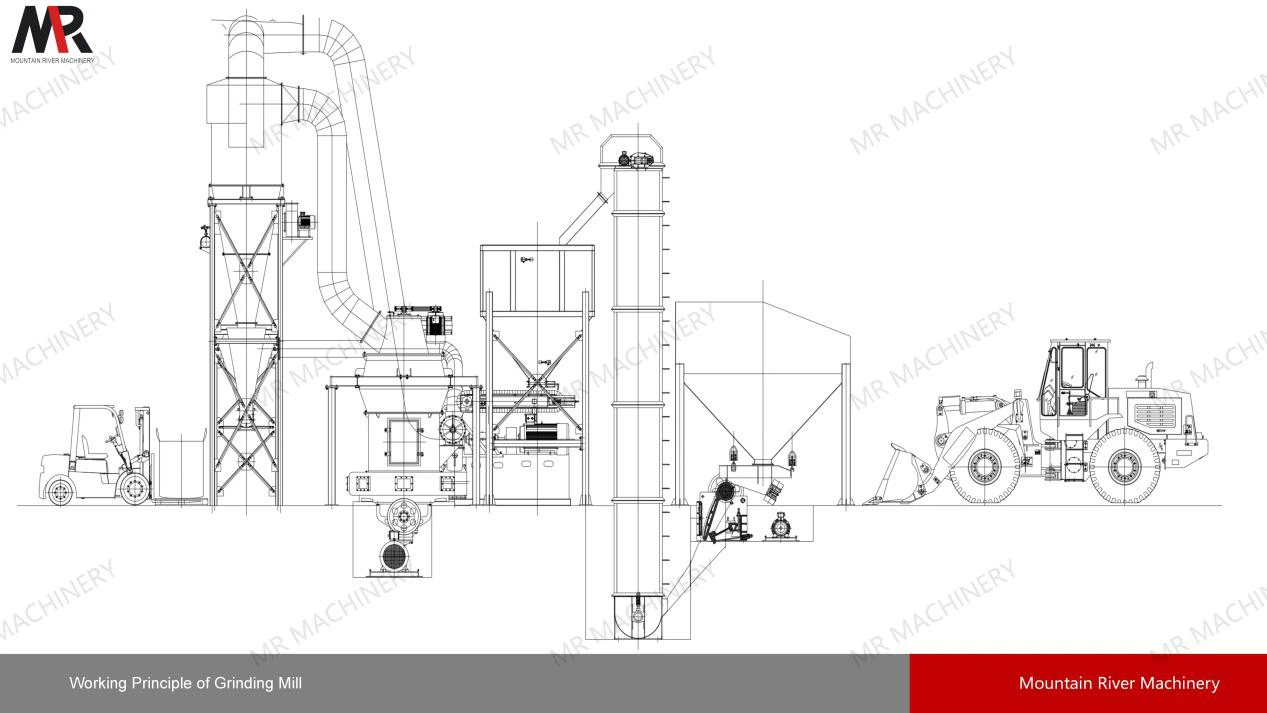

The production plant of MGW Intelligent Ginder consists of the belt feeder, air block feeder, main grinding mill, classifier, cyclone, fan, tube, and the pulse dust collector, etc. The crushed material will be fed into the main mill by the belt feeder. Under the action of centrifugal force, the material is grinded into fine powder by the grinding roller and grinding ring, and then separated by classifier and enters the tube to the pulse dust collector for collection.

Technical Parameters

Name & Model MGW110 MGW138 MGW175 MGW198 Roller qty. (pieces) 4 4 4/5 4/5 Outer diameter*height of roller (mm) Φ360*190 Φ460*240 Φ580*280/ Φ520*280 Φ620*300/ Φ520*300 Inner diameter*height of ring (mm) Φ1100*190 Φ1380*240 Φ1750*280 Φ1980*300 Main shaft speed (rpm) 120 96 75 70 Max.feeding size (mm) <30 <35 <40 <50 Output size (mm) 1.6-0.038 1.6-0.038 1.6-0.038 1.6-0.038 Capacity (t/h) 3.5-10 6.5-15 13-20 15-30 Overall dimension (mm) 8625*7933*

8642 9860*8340*

10227 13500*11500*

9500 15500*12000*

15000 Main mill motor (kw) 55 110 185 280 Classifier motor (kw) 11 22 37 55 Blower motor (kw) 55 110 200 280 Jaw crusher PE250*400 PE250*750 PE250*750 PE250*1200 Jaw crusher motor (kw) 22 22 22 37 Bucket elevator TH200*9M TH315*9.55M TH315*11.02M TH400*12.5M Bucket elevator motor (kw) 3 4 4 7.5 Belt feeder (mm) QB400*2500 QB500*3000 QB500*3000 QB500*6000 Belt feeder motor (kw) 1.5 3 4 4 Air block feeder GF-Φ400 GF-Φ500 GF-Φ500 GF-Φ500 Air block feeder motor (kw) 2.2 4 5.5 5.5

Name & Model | MGW110 | MGW138 | MGW175 | MGW198 |

Roller qty. (pieces) | 4 | 4 | 4/5 | 4/5 |

Outer diameter*height of roller (mm) | Φ360*190 | Φ460*240 | Φ580*280/ Φ520*280 | Φ620*300/ Φ520*300 |

Inner diameter*height of ring (mm) | Φ1100*190 | Φ1380*240 | Φ1750*280 | Φ1980*300 |

Main shaft speed (rpm) | 120 | 96 | 75 | 70 |

Max.feeding size (mm) | <30 | <35 | <40 | <50 |

Output size (mm) | 1.6-0.038 | 1.6-0.038 | 1.6-0.038 | 1.6-0.038 |

Capacity (t/h) | 3.5-10 | 6.5-15 | 13-20 | 15-30 |

Overall dimension (mm) | 8625*7933* 8642 | 9860*8340* 10227 | 13500*11500* 9500 | 15500*12000* 15000 |

Main mill motor (kw) | 55 | 110 | 185 | 280 |

Classifier motor (kw) | 11 | 22 | 37 | 55 |

Blower motor (kw) | 55 | 110 | 200 | 280 |

Jaw crusher | PE250*400 | PE250*750 | PE250*750 | PE250*1200 |

Jaw crusher motor (kw) | 22 | 22 | 22 | 37 |

Bucket elevator | TH200*9M | TH315*9.55M | TH315*11.02M | TH400*12.5M |

Bucket elevator motor (kw) | 3 | 4 | 4 | 7.5 |

Belt feeder (mm) | QB400*2500 | QB500*3000 | QB500*3000 | QB500*6000 |

Belt feeder motor (kw) | 1.5 | 3 | 4 | 4 |

Air block feeder | GF-Φ400 | GF-Φ500 | GF-Φ500 | GF-Φ500 |

Air block feeder motor (kw) | 2.2 | 4 | 5.5 | 5.5 |

Technical Skills of Operation

Before the Raymond mill starts working, we only need to do the following work to effectively keep the production capacity stable:

(1) Before starting the grinder machine, it is necessary to check the sealing of the powder locking device and make appropriate adjustments to improve its ability to receive powder.

(2) According to the actual working conditions of the mill machine, control the appropriate amount of material, adjust the air duct valve in time, adjust the material temperature, and ensure that the material temperature is moderate. This can avoid excessive material supply and air duct blockage.

(3) Regularly check the wear degree of the classifier, grinding knives, grinding roller, grinding ring and other spare parts inside the main milling machine, replace the spare parts inside the grinding mill in time and observe the material discharge volume.

(4) Clean the internal parts of the grinding machine regularly, remove the powder accumulated on the blades and grinding rollers and rings, and ensure internal cleanliness.

(5) Check the quality of the engine oil to ensure that the oil viscosity is appropriate, ensure timely lubrication of the bearings, and improve the productivity of the Raymond mill.

Through regular inspection, maintenance and care of the equipment, the output of Raymond mill can be effectively improved and production efficiency can be guaranteed. At the same time, during the operation, attention should be paid to following the equipment operating procedures to ensure the normal operation of the equipment.