Mining Machine Ball Mill Pruduct

Ball mill is a traditional material grinding device with a history of more than 100 years. Ball mill is a main equipment that processes solid materials into fine powder during operation. It is widely used in mineral processing, metallurgy, chemical industry, cement, ceramics, construction, electricity, pharmaceuticals and defense industry.

Introduction

Ball mill is a traditional material grinding device with a history of more than 100 years. Ball mill is a main equipment that processes solid materials into fine powder during operation. It is widely used in mineral processing, metallurgy, chemical industry, cement, ceramics, construction, electricity, pharmaceuticals and defense industry.

Application

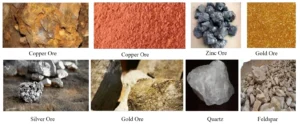

The ball mill machine is usted in gold, silver, lead, zinc, copper, molybdenum, iron, lead, manganese, tungsten, cement, ceramics, barite, bauxite, limestone, gypsum, calcium carbonate, coal, graphite, feldspar, potassium feldspar, phosphate rock, fluorite, clay and other ferrous and non-ferrous metal materials.

Structure

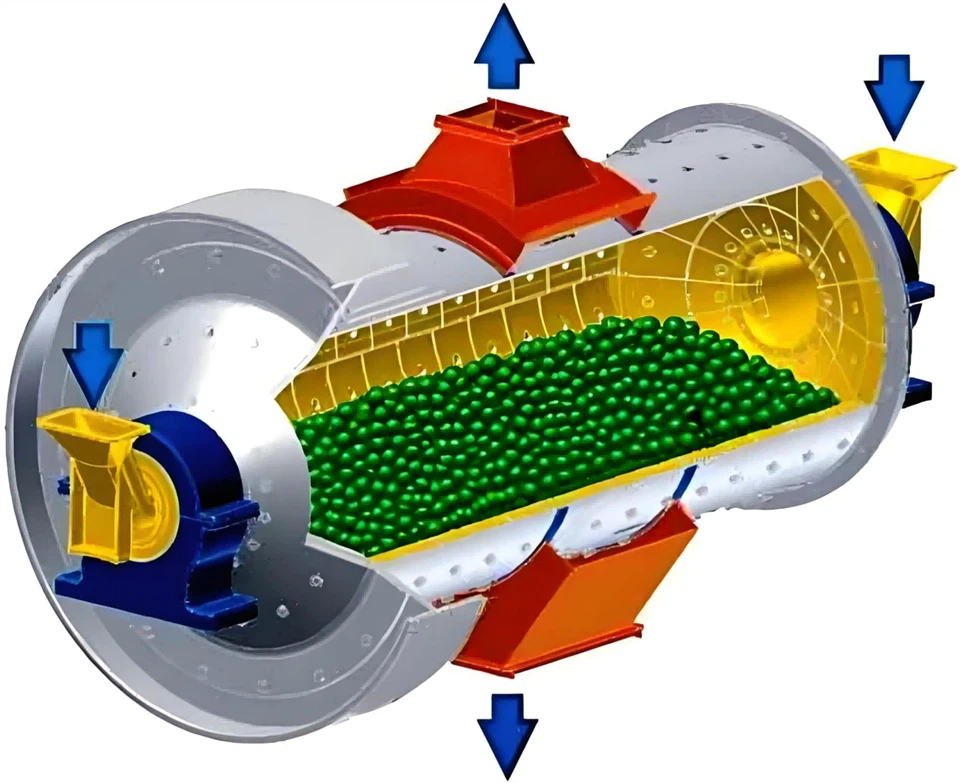

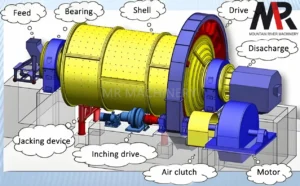

The ball mill is composed of the cylinder, feeder, feed screw, bearing cover, bearing seat, bracket, flower plate, drive seat, bridge bearing seat, pinion, reducer, coupling, motor, large gear, large liner and other main parts.

Classification

There are two grinding methods for ball mills, namely dry or wet grinding. The grinding methods are different for different ores and other grindable materials.

According to the Ratio of the Length to the Diameter of the Cylinder (Aspect Ratio):

Short mill: A ball mill with an aspect ratio of less than 2, which generally called a ball mill. Most of them are single-bin.

Medium-long mill: The aspect ratio is about 3.

Long mill: When the aspect ratio is greater than 4, it is called a long mill or tube mill.

The interior of medium-long mills and long mills is generally divided into 2 to 4 bins.

According to whether it is Operated Continuously, it can be Divided into: Continuous Mill and Intermittent Mill.

According to the Transmission Method, it can be Divided into:

Center drive mill: The motor drives the hollow shaft at the discharge end of the mill through the reducer to drive the mill body to rotate. The output shaft of the reducer is in the same straight line with the center line of the mill.

Edge drive mill: The motor drives the large gear fixed on the discharge end cylinder through the reducer to drive the mill body to rotate.

According to the Unloading Method:

Tail discharge mill: the material to be ground is fed from one end of the mill and discharged from the other end

Middle discharge mill: the material to be ground is fed from both ends of the mill and discharged from the middle.

According to the Shape of the Grinding Medium in the Mill:

Ball mill: the grinding medium in the mill is mainly steel balls or steel segments – the most common.

Baseball mill: 2 to 4 bins, the first bin: cylindrical steel rod grinding medium, the next few bins are filled with steel balls or steel segments.

Gravel mill: the grinding medium is gravel, pebbles, porcelain balls and corundum balls, etc., with granite or porcelain materials as lining.

According to the Operating Process, it can be Divided into: Dry Mill and Wet Mill.