Ball Mill Griniding Machine

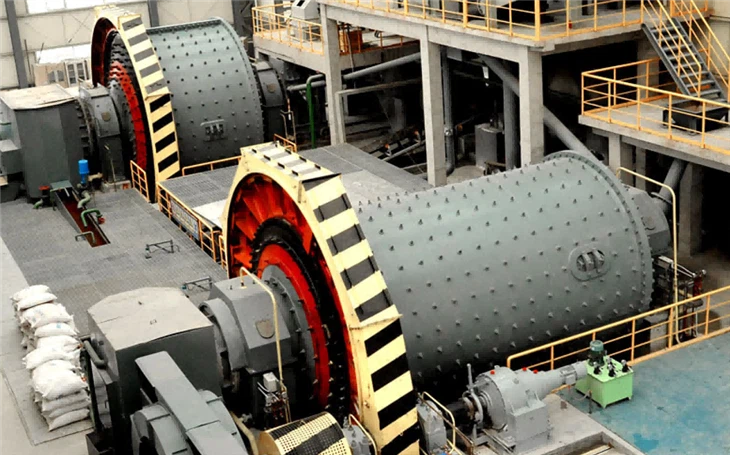

Ball mill is a traditional material grinding device with a history of more than 100 years. Ball mill is a main equipment that processes solid materials into fine powder during operation. It is widely used in mineral processing, metallurgy, chemical industry, cement, ceramics, construction, electricity, pharmaceuticals and defense industry.

Introduction

Ball mill is a traditional material grinding device with a history of more than 100 years. Ball mill is a main equipment that processes solid materials into fine powder during operation. It is widely used in mineral processing, metallurgy, chemical industry, cement, ceramics, construction, electricity, pharmaceuticals and defense industry.

Application

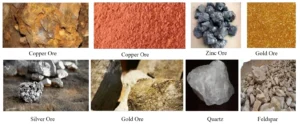

The ball mill machine is usted in gold, silver, lead, zinc, copper, molybdenum, iron, lead, manganese, tungsten, cement, ceramics, barite, bauxite, limestone, gypsum, calcium carbonate, coal, graphite, feldspar, potassium feldspar, phosphate rock, fluorite, clay and other ferrous and non-ferrous metal materials.

Working Principle

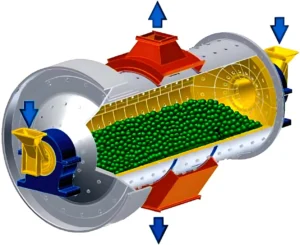

When the ball mill is working, the torque is transmitted to the large and small gears of the ball mill through the motor and reducer, so that the ball mill barrel rotates. Materials can be fed from the feeding end of the barrel. After the materials enter the ball mill barrel, they rotate at a constant speed. In the cylinder, due to the impact and self-grinding of the steel balls and the ore itself, the material is crushed under pressure. Since materials are continuously fed into the feed end, the pressure causes the materials in the barrel to move from the feed end to the discharge end. In this way, the materials reaching the final particle size are discharged from the discharging end of the ball mill barrel to form effective granular finished products. During wet grinding, the corresponding effective liquid is added into the cylinder, and the material and liquid are mixed and stirred and brought out by the water flow; during dry grinding, the material is brought out by the airflow formed by the exhaust pipe at the discharge end. The mill has a discharge grid at the discharge end. The mill relies on the grid plate to force the ore to be discharged. The slurry surface in the cylinder is low, which reduces the over-grinding of the ore and prevents the discharge of steel balls.

Advantages

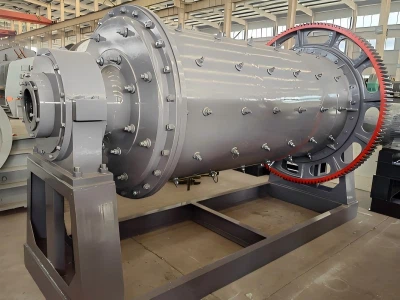

1.Static and dynamic bearing works with high energy ball mill,which makes ball mill machine works more efficienly,stable and reliable operation, new motor energy saving and environmental protection.

2.The hollow shaft is made of cast steel, the rotating gear is made of cast gear hobbing, and the cylinder is inlaid with wear-resistant lining plates, which are removable and have good wear resistance.

3.The oil mist lubrication device ensures reliable lubrication of large and small gears and slow transmission, which is convenient for maintenance and startup.

4.The lining plate and grinding body can be made of alumina ceramics, quartz, and special materials. Hard minerals are designed to be free of iron pollution, which reduces the breakage rate and improves the grinding efficiency.

Technical Parameters Of The Most Popular Mining Ball Mill

Model | Power (kW) | Thickness (mm) | Ball load (t) | Weight (t) |

φ900*1800 | 18.5 | 10 | 1.5 | 4.6 |

φ900*3000 | 22 | 10 | 2.7 | 5.6 |

φ1200*2400 | 30 | 12 | 3 | 12 |

φ1200*3000 | 37 | 12 | 3.5 | 12.8 |

φ1200*4500 | 55 | 12 | 5 | 13.8 |

φ1500*3000 | 75 | 16 | 7.5 | 15.6 |

φ1500*4500 | 110 | 16 | 7.5 | 21 |

φ1500*5700 | 130 | 16 | 12 | 25 |

φ1830*3000 | 130 | 18 | 11 | 28 |

φ1830*4500 | 155 | 18 | 15 | 32 |

φ1830*6400 | 210 | 18 | 21 | 34 |

φ1830*7000 | 245 | 18 | 23 | 36 |

φ2100*3000 | 210 | 20 | 19 | 43 |

φ2100*4500 | 245 | 20 | 24 | 46 |

φ2100*7000 | 280 | 20 | 26 | 50 |

φ2200*6500 | 380 | 22 | 35 | 52.8 |

φ2200*7000 | 380 | 22 | 35 | 54 |

φ2200*7500 | 380 | 22 | 35 | 56 |

φ2400*3000 | 245 | 24 | 27 | 60 |

φ2400*4500 | 320 | 24 | 30 | 65 |

φ2400*7000 | 475 | 24 | 54 | 71 |

φ2700*3600 | 400 | 25 | 39 | 83 |

φ2700*4000 | 400 | 25 | 40 | 85 |

φ2700*4500 | 430 | 25 | 48 | 89 |

φ2700*6000 | 630 | 25 | 53 | 93 |

φ3200*3600 | 560 | 30 | 52 | 120 |

φ3200*4500 | 800 | 30 | 65 | 125 |

φ3200*5400 | 800 | 30 | 81.6 | 130 |

φ3000*11000 | 1250 | 30 | 95~100 | 155 |

φ3600*4000 | 800 | 35 | 75 | 185 |