High Efficiency PF Impact Crusher

The impact crusher is a high-efficiency crushing device that utilizes impact energy to crush materials. It is widely used in mining, metallurgy, chemical, building materials, highway, railway, and water conservancy projects, primarily for medium and fine crushing of materials with medium to low hardness, such as limestone, granite, and concrete.

Introduction

The impact crusher is a high-efficiency crushing device that utilizes impact energy to crush materials. It is widely used in mining, metallurgy, chemical, building materials, highway, railway, and water conservancy projects, primarily for medium and fine crushing of materials with medium to low hardness, such as limestone, granite, and concrete.

Unlike jaw crushers, which primarily use compression crushing, impact crushers emphasize the “stone-on-stone” impact crushing principle, resulting in superior particle shape, mostly cubic, and playing a crucial role in the production of aggregates and sand for construction.

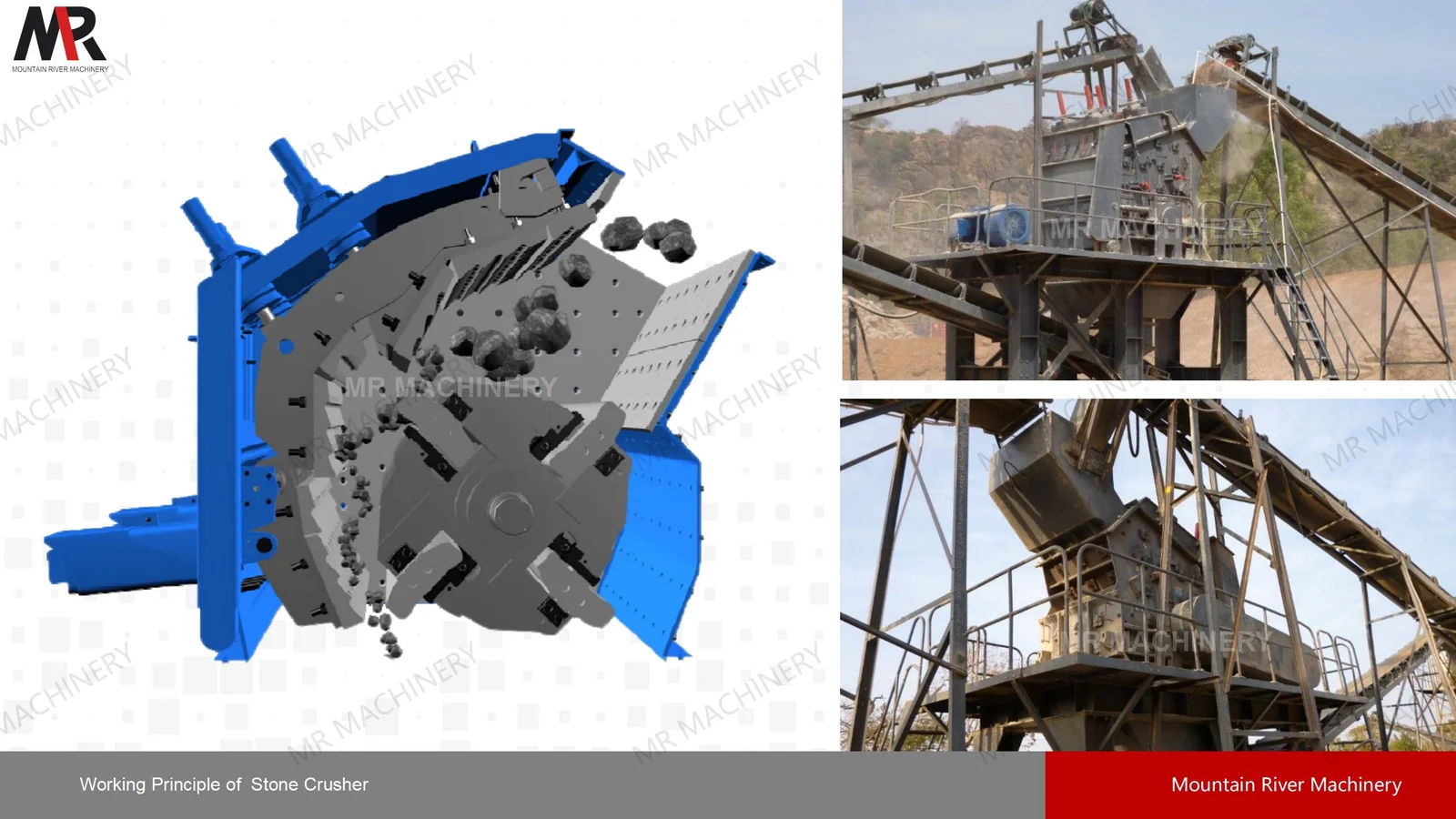

Working Principle

When material enters the crushing chamber through the feed inlet, it first collides with the hammers on the high-speed rotating rotor. Driven by a motor, the rotor rotates at a specific speed, giving the hammers sufficient kinetic energy; this stage is called primary impact crushing.

Subsequently, the accelerated material is tangentially projected towards the first-stage impact plate. The serrated design of the impact plate surface enhances the crushing effect while simultaneously causing secondary crushing and rebound of the material. During this process, the material violently collides with the feed stream continued to be ejected by the rotor, forming a “stone-on-stone” crushing mode, a mechanism that significantly improves crushing efficiency.

After multiple impacts and counter-impacts, the material continuously develops cracks and breaks apart within the crushing chamber. When the particle size of the material is smaller than the set gap between the impact plate and the rotor, it reaches the qualified particle size and is discharged from the outlet.

Main Structure

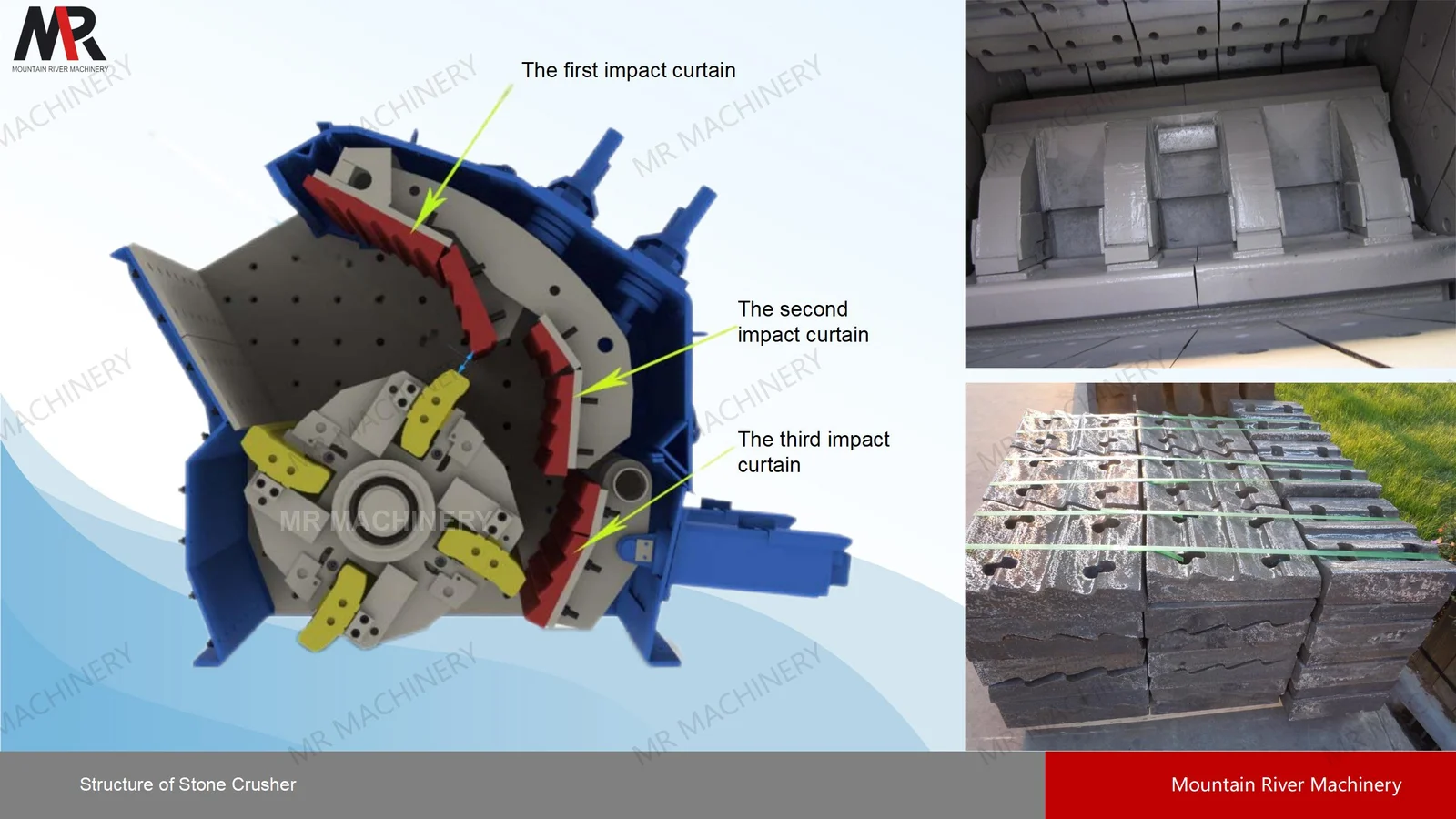

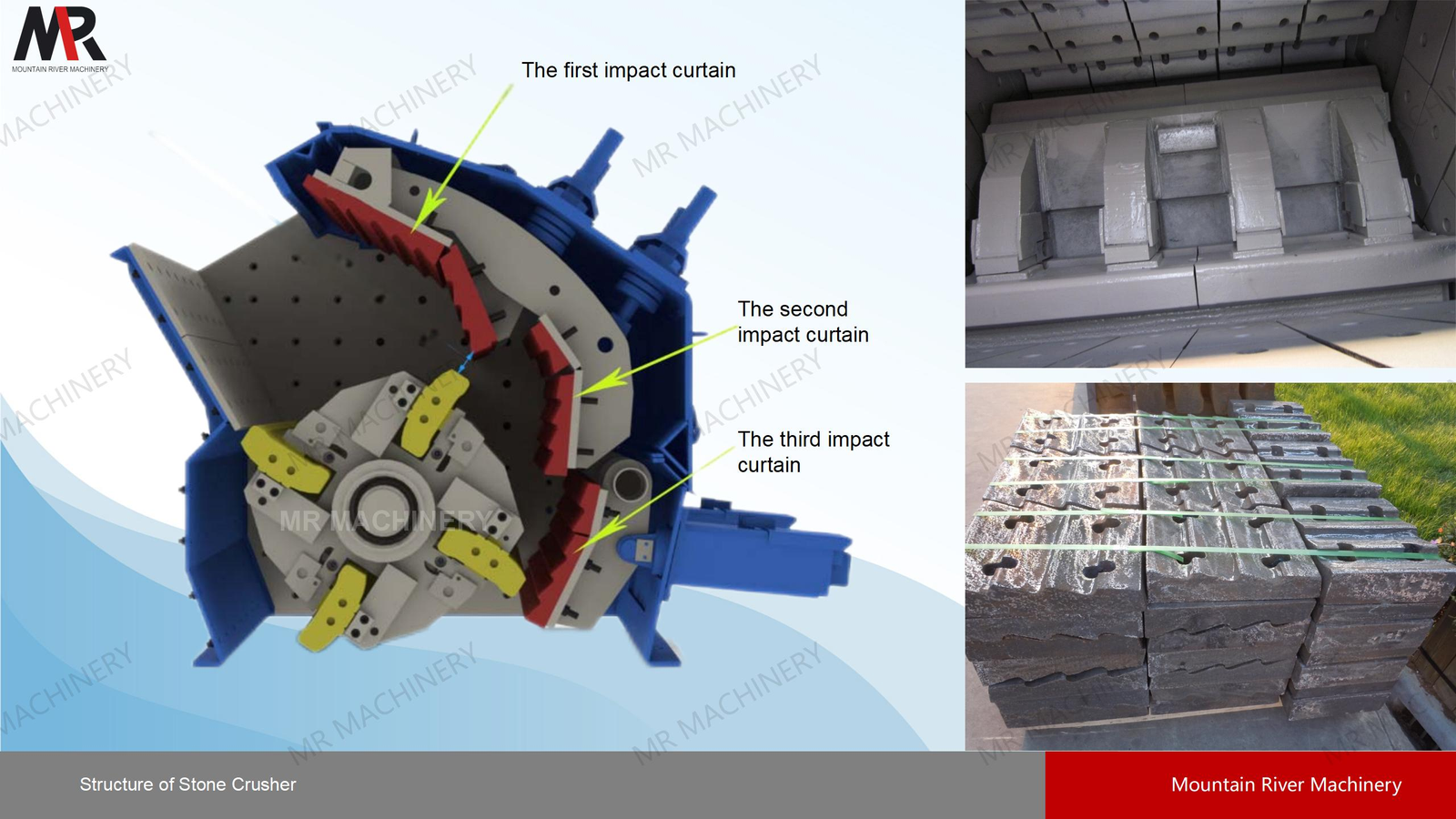

An impact crusher mainly consists of the following core components:

Rotor:Composed of a main shaft, turntable, hammers, and pins. It provides the core kinetic energy required for crushing; its rotational speed and weight directly determine the crushing efficiency and capacity.

Hammers:The vulnerable parts that directly contact the material, responsible for impacting it. They are usually made of high-strength, wear-resistant alloy materials and are a key point for equipment maintenance.

Impact Plates:The “anvil” of the crusher. They are usually multi-stage, with a zigzag or arc-shaped design, used to withstand the impact of the material and rebound it. The gap between the impact plate and the rotor is adjustable to control the output particle size.

Advantage

The impact crusher employs a unique “stone-on-stone” crushing principle, fundamentally different from jaw crushers or cone crushers that primarily rely on compression. Its high-speed rotating rotor propels material against the impact plates, achieving highly efficient crushing through intense collisions. It boasts a large single-machine crushing ratio, capable of processing large materials of 500-800 mm into smaller pieces (below 25 mm) in a single pass.

This principle directly results in superior finished product quality. The output particles are predominantly cubic with low needle-like and flaky content, exhibiting a robust internal structure. It is an ideal choice for producing high-grade concrete and high-quality asphalt aggregate, significantly enhancing the strength and durability of building materials.