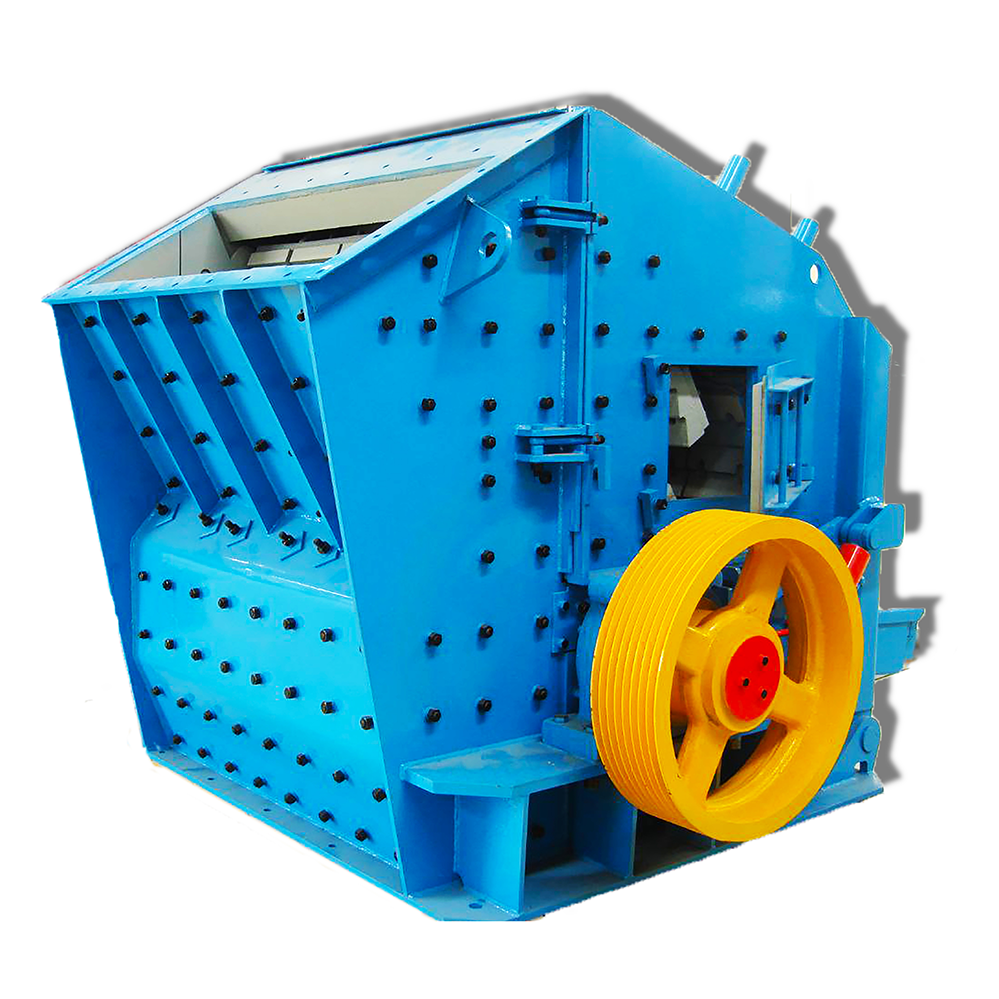

PFW Hydraulic Ore Impact Crusher Machine

PFW Series Impact Crusher delivers two core values through the introduction of a high-efficiency hydraulic control system: firstly, it significantly reduces wear costs and extends the replacement cycle for hammers and liners; secondly, it enhances operational reliability, product homogeneity, and equipment protection grade, with its overall performance surpassing that of traditional models.

Introduction

PFW Series Impact Crusher delivers two core values through the introduction of a high-efficiency hydraulic control system: firstly, it significantly reduces wear costs and extends the replacement cycle for hammers and liners; secondly, it enhances operational reliability, product homogeneity, and equipment protection grade, with its overall performance surpassing that of traditional models.

Application

The PFW Series Impact Crusher is a highly efficient and versatile crushing device, with its core design optimized for processing medium and low-hardness materials. It excels at handling various non-metallic minerals and raw materials such as limestone, calcite, gypsum, kaolin, talc, barite, feldspar, graphite, rare earth, clay, and dolomite. Thanks to its excellent crushing efficiency and superior product particle shape, it has become a critical piece of equipment in production lines for industries including metallurgy, mining, cement, chemical, refractory materials, and ceramics. Simultaneously, it plays an indispensable role in infrastructure construction fields such as highways and water conservancy projects, as well as in the large-scale production of construction aggregate and manufactured sand.

Technical Parameters

Model | Rotor Specifications (mm) | Inlet Size (mm) | Feed Particle Size (mm) | Capacity (t/h) | Weight(t) |

PFW1214III | Φ1150×1400 | 570×1430 | <250 | 90-170 | 19 |

PFW1315III | Φ1300×1500 | 625×1530 | <300 | 180-270 | 25 |

PFW1318III | Φ1300×1800 | 625×1830 | <300 | 220-300 | 30 |

PFW1415III | Φ1400×1500 | 800×1530 | <350 | 250-350 | 32 |

PFW1214II | Φ1150×1400 | 1100×1430 | ≤500 | 130-200 | 22 |

PFW1315II | Φ1300×1500 | 1200×1530 | ≤600 | 180-320 | 29 |

PFW1318II | Φ1300×1800 | 1200×1830 | ≤700 | 240-400 | 34 |

PFW1415II | Φ1400×1500 | 1450×1530 | ≤800 | 260-450 | 36 |

Comparison with PF Impact Crusher

The core upgrade of the PFW Series lies in the incorporation of an advanced hydraulic control system. This system significantly simplifies equipment maintenance and adjustment operations, improving operational safety and efficiency. Through optimized design and overload protection, it extends the service life of wear parts and reduces downtime. Furthermore, it further enhances the quality of the finished product’s particle shape. This grants the PFW Series higher reliability and comprehensive economic efficiency in projects demanding continuous production and high-quality aggregate.

Common Faults and Diagnostic Procedures

1.Severe Vibration and Bearing Temperature Rise

Root Cause:

The fundamental cause is the failure of rotor dynamic balance. If the hammers are not balanced during assembly, the high-speed rotating rotor will generate significant centrifugal force, leading to severe vibration/imbalance.

Corrective Measures:

The core objective is to ensure and restore rotor balance.

If vibration intensifies during operation, stop the machine immediately to inspect the wear condition of the hammers.

If the hammers have not reached their wear limit, rotor balance can be restored by swapping their installation positions (changing sides or locations).

If the hammers have reached their wear limit, they must be replaced as a complete set.

2.Excessive Wear of Wear Parts

Root Cause:

During the production process, if the feed material size is too large, too hard, or contains wet clay, it can exceed the effective striking range of the hammers, greatly increasing ineffective wear. Furthermore, failure to timely adjust the gap between the hammers and impact plates can prevent effective primary crushing in the first chamber, causing material to impact repeatedly and accelerating the wear of these parts.

Corrective Measures:

Strictly ensure during feeding that the material size and moisture content comply with the equipment’s specified range. Regularly inspect the wear condition of the wear parts. Also, periodically check and adjust the gap between the hammers and impact plates, ensuring all bolts are tightened during adjustment.