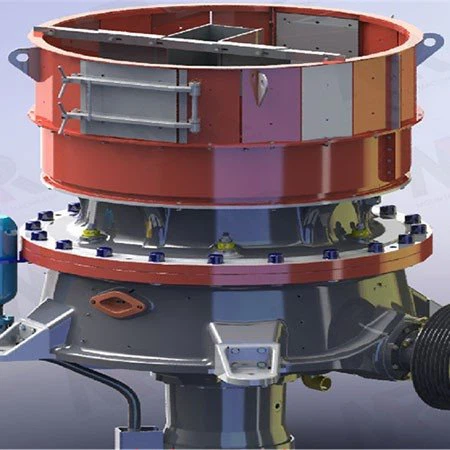

HST Single-cylinder Hydraulic Cone Crusher

HST single-cylinder hydraulic cone crusher is a typical crushing equipment used for medium crushing and fine crushing of hard materials.

Introduction

HST single-cylinder hydraulic cone crusher adopts the latest technology. It is with new structure, optimized lamination cavity and intelligent automatic control system, which makes the crushing efficiency higher and the finished product shape better.

Application

HST single cylinder hydraulic cone crusher can crush materials like limestone, marble, granite, river stone, basalt, quartz, iron ore, copper ore, gold ore, etc.

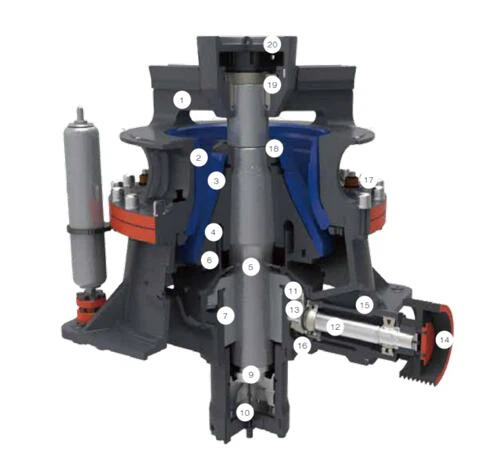

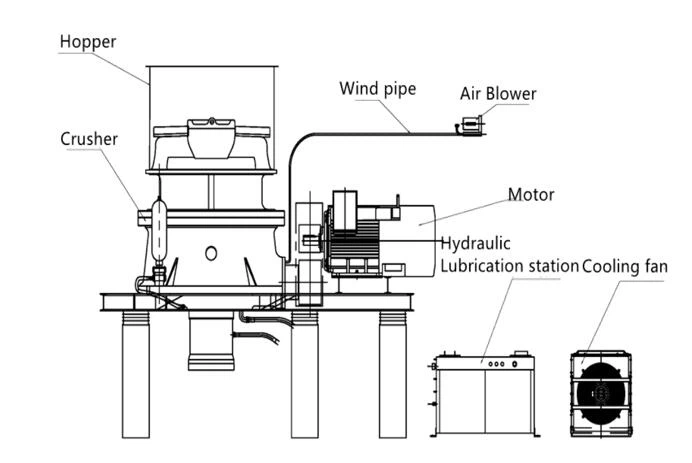

Main Structure

(1) Upper Frame | (2) Concave | (3) Mantle | (4) Movable Cone |

(5) Main shaft | (6) Dustproof Sealing Ring | (7) Eccentric Sleeve | (8) Lower Frame |

(9) Thrust Bearing | (10) Hydraulic Cylinder | (11) Big Gear | (12) Horizontal Counter shaft |

(13) Small Gear | (14) Pulley | (15) Horizontal Countershaft Frame | (16) Lubricating Oil Return |

(17) Concave Locknut | (18) Mantle Locknut | (19) Top Bearing | (20) Top Bearing Cap |

Technical Advantages

(1) By adopting the principle of lamination crushing, better output of cubic finished products can be obtained.

(2) Higher crushing ratio, higher output capacity, higher production efficiency.

(3) Fully automatic control, lower operating cost and longer life cycle.

(4) Multiple cavities to meet various process requirements.

Technical Parameters

Model | Cavity | Feeding Opening (mm) | Minimum Discharging Size(mm) | Capacity (t/h) | Power(kw) | Overall Dimension (mm) |

HST100 | EC | 240 | 22 | 85-170 | 90 | 1550X1575 X2545 |

MC | 200 | 19 | 70-130 | |||

F | 135 | 10 | 45-115 | 1550X1575 X1965 | ||

MF | 65 | 8 | 35-80 | |||

EF | 35 | 4 | 27-60 | |||

HST160 | EC | 360 | 25 | 120-345 | 132 (Max 160) | 1875X1920 X3195 |

MC | 300 | 22 | 105-305 | |||

C | 235 | 19 | 90-275 | |||

F | 185 | 13 | 66-210 | 1875X1920 X2400 | ||

MF | 90 | 10 | 65-165 | |||

EF | 50 | 6 | 48-105 | |||

HST250 | EC | 450 | 35 | 255-605 | 220 (Max 250) | 2100X2320 X4096 |

MC | 400 | 29 | 215-515 | |||

C | 300 | 25 | 190-490 | |||

F | 215 | 16 | 110-395 | 2100X2320 X2780 | ||

MF | 110 | 13 | 115-340 | |||

EF | 70 | 8 | 90-255 | |||

HST315 | EC | 560 | 41 | 335-1050 | 315 | 2380X2735 X4630 |

MC | 500 | 38 | 305-895 | |||

F | 275 | 16 | 170-665 | 2380X2735 X3265 | ||

MF | 135 | 16 | 190-505 | |||

EF | 65 | 13 | 205-320 | |||

HST500 | EC | 560 | 54 | 575-1505 | 500 | 2490X2909 X4892 |

MC | 465 | 54 | 550-1435 | |||

F | 315 | 16 | 290-900 | |||

MF | 265 | 16 | 330-1015 | 2490X2909 X4267 | ||

EF | 195 | 16 | 315-975 |