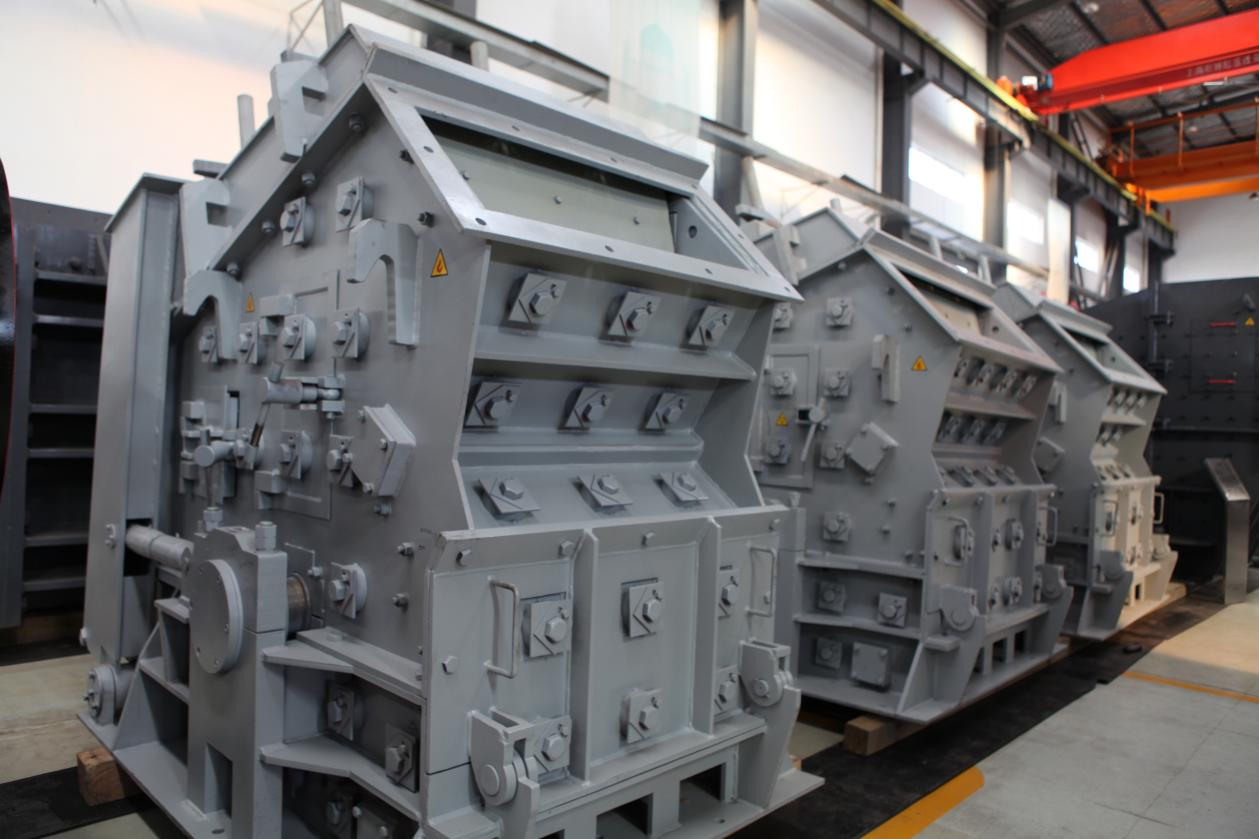

PF Impact Crusher Machine for Mining

The PF Impact Crusher is suitable for processing various materials with a feed size ≤500mm (a common feed size, capable of handling larger material sizes as well) and a compressive strength ≤360MPa. This equipment offers significant advantages, including a high reduction ratio, outstanding efficiency, and convenient maintenance.

Introduction

The PF Impact Crusher is suitable for processing various materials with a feed size ≤500mm (a common feed size, capable of handling larger material sizes as well) and a compressive strength ≤360MPa. This equipment offers significant advantages, including a high reduction ratio, outstanding efficiency, and convenient maintenance. The processed aggregate exhibits excellent particle shape, predominantly dense and cubic, making it an ideal processing equipment for producing high-quality aggregate required for high-grade highways, railways, water conservancy projects, and similar engineering works. It is widely used in road construction, water conservancy projects, and construction aggregate production.

Application

The PF Impact Crusher is suitable for processing a variety of medium-hard and hard materials, covering common rocks and metallic ores. Typical applicable materials include:

Common rocks: limestone, marble, granite, river pebble, basalt, quartzite, etc.

Technical Parameters

Model | Rotor Specifications (mm) | Inlet Size (mm) | Feed Particle Size (mm) | Capacity (t/h) | Weight (t) |

PF1010 | Φ1050×1000 | 400×1080 | <350 | 50-80 | 11.4 |

PF1210 | Φ1250×1050 | 400×1080 | <350 | 60-120 | 14.2 |

PF1214 | Φ1250×1400 | 400×1430 | <350 | 80-160 | 15.8 |

PF1315 | Φ1300×1500 | 860×1520 | <350 | 120-260 | 19.3 |

Main Wear Parts

Hammers

Function: Mounted on the rotor, they directly impact the material at high speed, serving as the primary component performing the crushing work.

Features: Typically cast from ultra-wear-resistant materials such as high-chromium alloy cast iron. Their design must facilitate easy installation, removal, and angle adjustment to fully utilize the material. Their wear resistance is a key indicator of the equipment’s economic efficiency.

Impact Plates

Function: Fixed on the impact frame inside the housing, they collide with material thrown by the hammers, achieving secondary crushing and controlling the material’s rebound path.

Features: Also manufactured from wear-resistant alloy steel. They are usually designed with multiple stages (e.g., primary and secondary). Their shape and the gap to the rotor directly determine crushing efficiency and product size.

Side Liner Plates

Function: Installed on both inner sides of the housing to protect the frame from material abrasion.

Features: Classified as auxiliary wear parts. Their replacement cycle is typically longer than that of hammers and impact plates, but they are crucial for protecting the main machine structure.

Plant Site