HP Multi-Cylinder Hydraulic Cone Crusher

HP multi-cylinder hydraulic cone crusher is a typical crushing equipment used for medium crushing and fine crushing of hard materials.

Introduction

HP multi-cylinder hydraulic cone crusher is a typical crushing equipment used for medium crushing and fine crushing of hard materials. HP multi-cylinder hydraulic cone crusher is widely used in metallurgy, mining, chemical industry, cement, construction, refractory materials and ceramics and other industries.

Application

CS series HP Multi-cylinder Hydraulic cone crusher can crush materials like limestone, marble, granite, river stone, basalt, quartz, iron ore, copper ore, gold ore, etc.

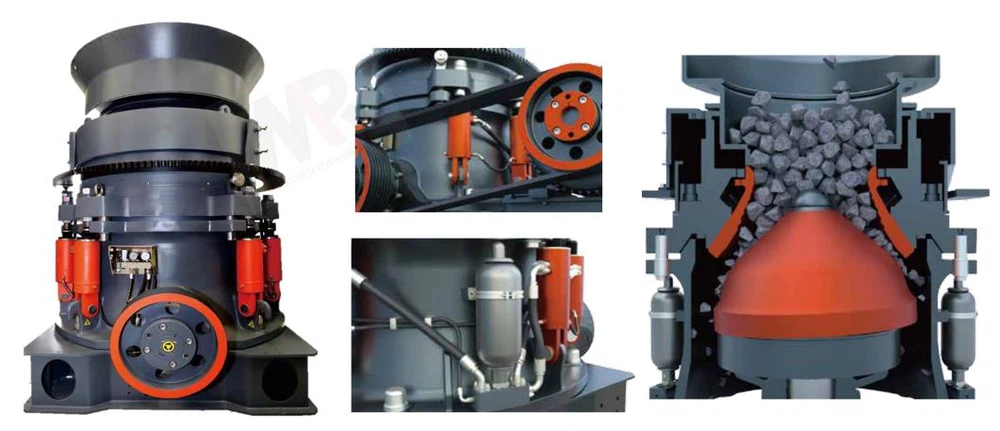

Main Structure

(1) Diving Plate | (2) Adjustment Ring | (3) Concave | (4) Mantle | (5) Movable Cone |

(6) Main Shaft | (7) Frame | (8) Big Gear | (9) Eccentric Bush | |

(11) Adjustment Cap | (12) Supporting Bush | (13) Spring | (14) Bowl Bearing Frame | (10) Hopper |

(15) Small Gear | (16) Transmission Shaft | (17) Pulley |

Technical Advantages

(1) HP multi-cylinder hydraulic cone crusher is equipped with hydraulic system, integrated lubrication system and automatic control system, which ensures stable, convenient and reliable operation and greatly reduces downtime. At the same time, labor costs are reduced.

(2) HP multi-cylinder hydraulic cone crusher adopts the principle of lamination crushing, and the crushed finished product can have a cube shape,which is more competitive than the laminated size stones and can be sold with a higher price.

(3) HP multi-cylinder hydraulic cone crusher has multiple cavities, which is more convenient to apply to the requirements of secondary and tertiary crushing.

Technical Parameters

Model | Cavity | Discharge Setting Min.(mm) | Feeding Opening(mm) | Capacity (t/h) | Power(kw) | Weight(t) |

HP160 | (F) Fine | 13 | 95 | 120-200 | 160 | 13.4 |

(M)Medium | 16 | 120 | 140-220 | |||

(C)Coarse | 19 | 190 | 160-250 | |||

HP220 | (F)Fine | 13 | 105 | 150-210 | 220 | 18.1 |

(M)Medium | 16 | 150 | 170-250 | |||

(C)Coarse | 19 | 210 | 185-300 | |||

(EC)Extra Coarse | 25 | 230 | 220-400 | |||

HP400 | (F)Fine | 16 | 135 | 260-400 | 400 | 37 |

(M)Medium | 22 | 210 | 330-450 | |||

(C)Coarse | 30 | 290 | 400-500 | |||

(EC)Extra Coarse | 38 | 330 | 440-550 |