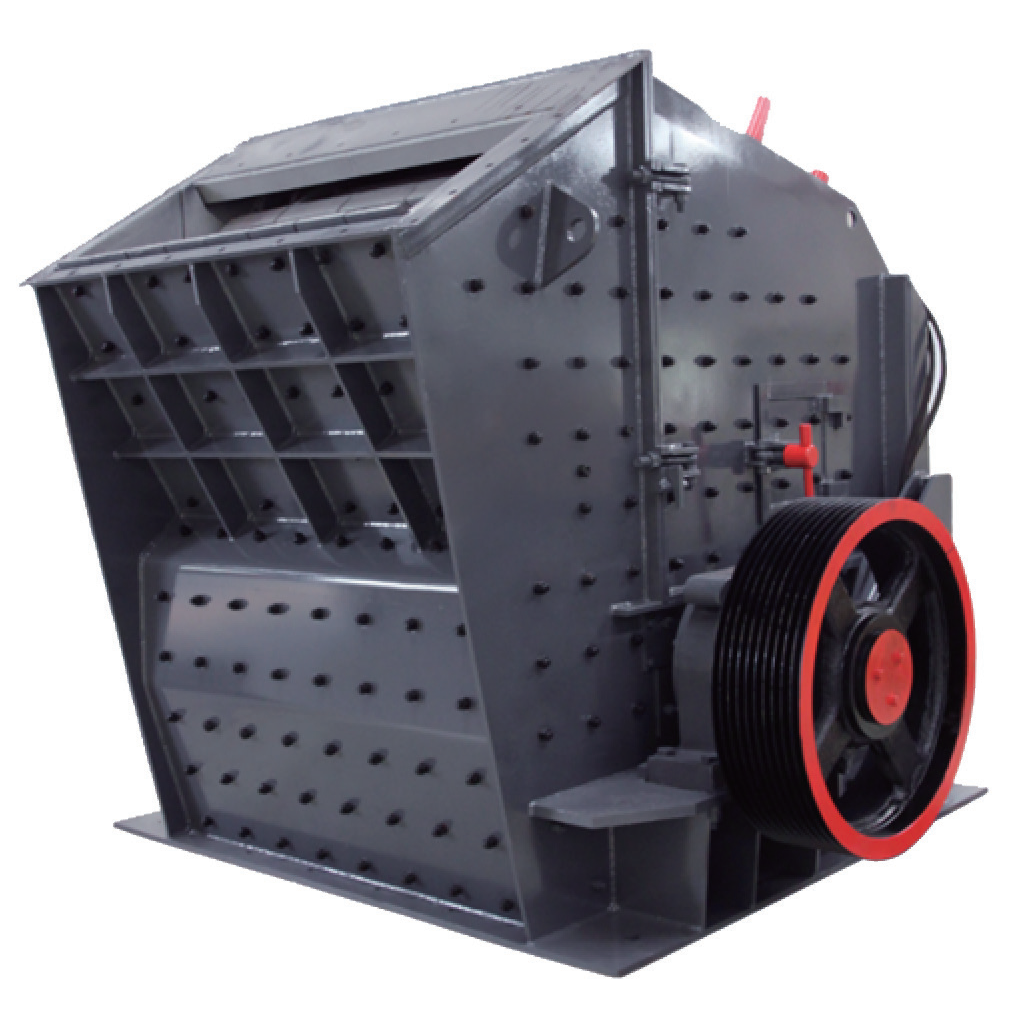

Efficient PFW Hydraulic Impact Crusher Machine

The PFW series impact crusher is a new generation of high-efficiency equipment featuring an advanced hydraulic control system. Compared with traditional models, its core advantages lie in extending the service life of wear parts (such as blow bars and liners) through the hydraulic system, while achieving comprehensive improvements in operational stability, product size control, and overload protection.

Introduction

The PFW series impact crusher is a new generation of high-efficiency equipment featuring an advanced hydraulic control system. Compared with traditional models, its core advantages lie in extending the service life of wear parts (such as blow bars and liners) through the hydraulic system, while achieving comprehensive improvements in operational stability, product size control, and overload protection.

Application

The PFW series impact crusher is a core crushing equipment widely used in multiple industrial fields. It is particularly suitable for processing various ores and materials with low to medium hardness, such as limestone, calcite, gypsum, talc, barite, kaolin, clay, dolomite, graphite, feldspar, and rare earth minerals.

This equipment is also extensively employed in industrial sectors including metallurgy, mining, cement, chemical engineering, refractory materials, and ceramics. Moreover, it is an indispensable piece of machinery in modern infrastructure construction, utilized in highway construction, hydraulic engineering, construction aggregate production, and manufactured sand processing. It provides high-quality sand and aggregate materials for various engineering projects.

Technical Parameters

Model Rotor Specifications (mm) Inlet Size (mm) Feed Particle Size (mm) Capacity (t/h) Weight(t) PFW1214III Φ1150×1400 570×1430 <250 90-170 19 PFW1315III Φ1300×1500 625×1530 <300 180-270 25 PFW1318III Φ1300×1800 625×1830 <300 220-300 30 PFW1415III Φ1400×1500 800×1530 <350 250-350 32 PFW1214II Φ1150×1400 1100×1430 ≤500 130-200 22 PFW1315II Φ1300×1500 1200×1530 ≤600 180-320 29 PFW1318II Φ1300×1800 1200×1830 ≤700 240-400 34 PFW1415II Φ1400×1500 1450×1530 ≤800 260-450 36

Model | Rotor Specifications (mm) | Inlet Size (mm) | Feed Particle Size (mm) | Capacity (t/h) | Weight(t) |

PFW1214III | Φ1150×1400 | 570×1430 | <250 | 90-170 | 19 |

PFW1315III | Φ1300×1500 | 625×1530 | <300 | 180-270 | 25 |

PFW1318III | Φ1300×1800 | 625×1830 | <300 | 220-300 | 30 |

PFW1415III | Φ1400×1500 | 800×1530 | <350 | 250-350 | 32 |

PFW1214II | Φ1150×1400 | 1100×1430 | ≤500 | 130-200 | 22 |

PFW1315II | Φ1300×1500 | 1200×1530 | ≤600 | 180-320 | 29 |

PFW1318II | Φ1300×1800 | 1200×1830 | ≤700 | 240-400 | 34 |

PFW1415II | Φ1400×1500 | 1450×1530 | ≤800 | 260-450 | 36 |

Advantages

Hydraulic System Integration: Equipped with a fully hydraulic control system, significantly enhancing operational convenience and maintenance efficiency.

High-Efficiency Rotor Design: Features a uniquely designed heavy-duty rotor structure with higher rotational inertia and impact energy, leading to a substantial increase in production efficiency.

Optimized Chamber Design: The refined multi-stage crushing chamber and impact plate curve effectively facilitate laminated crushing and shaping of materials, ensuring excellent particle shape and low flake content in the final aggregate.

Dual Model Configuration: Offers coarse crushing (two-chamber) and medium crushing (three-chamber) models to meet the demands of different crushing stages. The coarse crushing model can handle larger feed sizes and is suitable for primary crushing. The medium crushing model is specifically configured with a third-stage crushing and shaping chamber, enabling re-impact, grinding, and fine-tuning of materials, making it an ideal choice for producing high-quality manufactured sand.

Safety Usage Recommendations

Operational Safety Zone: During equipment operation, personnel and electrical switches should stay clear of the projection area of the rotor’s inertial force line.

Prohibited Actions During Operation: It is strictly forbidden to open inspection doors, observe inside, make adjustments, perform cleaning, or conduct any maintenance work while the equipment is running.

Material Control: Do not feed non-crushable materials that exceed the equipment’s crushing capacity to prevent damage.

Pre-Maintenance Preparation: Before performing any inspection or maintenance, the main power supply to the equipment must be disconnected.

Load Management: Overloading the equipment during operation is strictly prohibited.

Electrical Safety: All electrical equipment must be reliably grounded, and wiring should be properly insulated and installed within protective conduits.