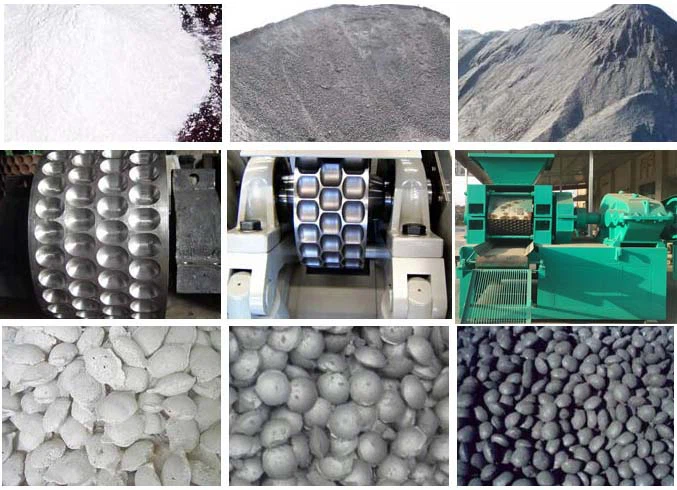

High Quality Charcoal Briquette Machine

Charcoal briquette machine is the equipment which can make briquette of charcoal mainly for BBQ.

Product Description

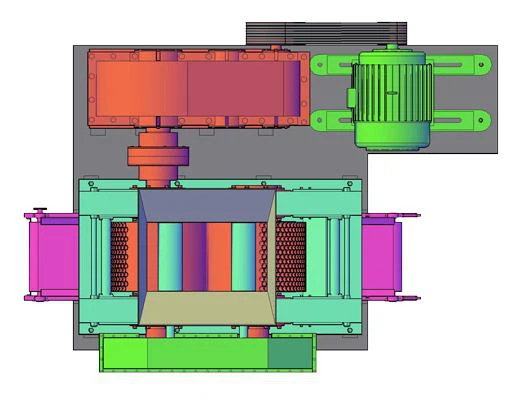

Charcoal briquette machine has two rollers which is pressed by the hydraulic cylinder. The two rollers will press the charcoal powder when the it passes from the space of the two rollers, and then the charcoal briquette will drop down by gravity.

Working Principle

The hydraulic cylinder will provide the pressure to the driven rollers and the passive roller will keep the same position, in this way, during charcoal materials are entered evenly into the feeding hopper of briquette machine, the two big rollers push raw materials with high pressure force, to press them into briquettes, and successfully complete drop from rollers. The shapes of Briquette are oval, pillow, soap, bar shape, round shape.

Applications of End Products

(1) For home stoven for keeping warm.

(2) Hot water boilers and the industrial boilers;

(3) Outdoor BBQ or Grill.

(4) Blast furnace fuel for metallurgical steelmaking.

Technical Parameters

Model | MRL-4 | MRL-6 | MRL-8 | MRL-10 | MRL-15 |

Capacity | 3-4t/h | 6t/h | 8t/h | 10t/h | 15t/h |

Roller width | 250mm | 240mm | 220mm | 300mm | 336mm/400mm |

Roller diameter | 360mm | 400mm | 450mm | 500mm | 650mm |

Power | 7.5 kW | 11 kW | 18.5kW | 22kW | 37kW |

Reducer | ZQ350 | ZQ400 | ZQ500 | ZQ500 | ZQ650 |

Pressure type | Mechincal | Mechincal | Mechincal | Hydraulic | Hydraulic |

Roller material | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn |

9Cr2Mo | 9Cr2Mo | 9Cr2Mo | 9Cr2Mo | 9Cr2Mo | |

wear- resistant alloy | wear- resistant alloy | wear- resistant alloy | wear- resistant alloy | wear- resistant alloy | |

Roller assemble | Split- clamp type | Split- clamp type | Split- clamp type | Temper assembly | Temper assembly |

Hardness of roller | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC |

Pressure structure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure |

Dimension(mm) | 1200x1150 x1835 | 1400x1298 x2125 | 1700x1510 x2200 | 2000x1960 x2440 | 2188x1972 x1670 |

Weight(kg) | 2100 | 2300 | 2750 | 5800 | 7600 |

Model | MRL-20 | MRL-30 | MRL-40 | Note |

Capacity | 20t/h | 30t/h | 40t/h | According to material |

Roller width | 428mm/500mm | 500mm | 00mm | |

Roller diameter | 750mm | 850mm | 1000mm | |

Power | 55kW | 90 kW | 110kW | |

Reducer | ZQ850 | ZQ1000 | ZQ1000 | standard configuration |

Pressure type | Hydraulic | Hydraulic | Hydraulic | patent |

Roller material | 65Mn | 65Mn | 65Mn | Casting |

9Cr2Mo | 9Cr2Mo | 9Cr2Mo | Forging | |

wear-resistant alloy | wear-resistant alloy | wear-resistant alloy | patent | |

Roller assemble | Temper assembly | Temper assembly | Temper assembly | patent |

Hardness of roller | 52-62 HRC | 52-62 HRC | 52-62 HRC | |

Pressure structure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure | patent (four rollers) |

Dimension(mm) | 2660x2300x1750 | 2965x2450x1980 | 3065x28850x2220 | |

Weight(kg) | 9000 | 15500 | 25000 |

Customer Site

FAQ

Q1: What is the material of the rollers?

A1: The raw material is 9Cr2Mo, one of the hard material with high tolerance.

Q2: What is the capacity of the briquette machine?

A2: The Capacity of the briquette machine varies from 5tons to 50 tons per hour.

Q3: How long can the roller be working?

A3: The roller is made of hard material, the service life of the rollers depends on the type of raw material for briquette. Normally for coal briquette, one pair of roller can last for 24 months.

Q4:What is the pressure between the two rollers?

A4: Normally the pressure between the two rollers is 3-5 tons.