Hydraulic Briquette Press Machine

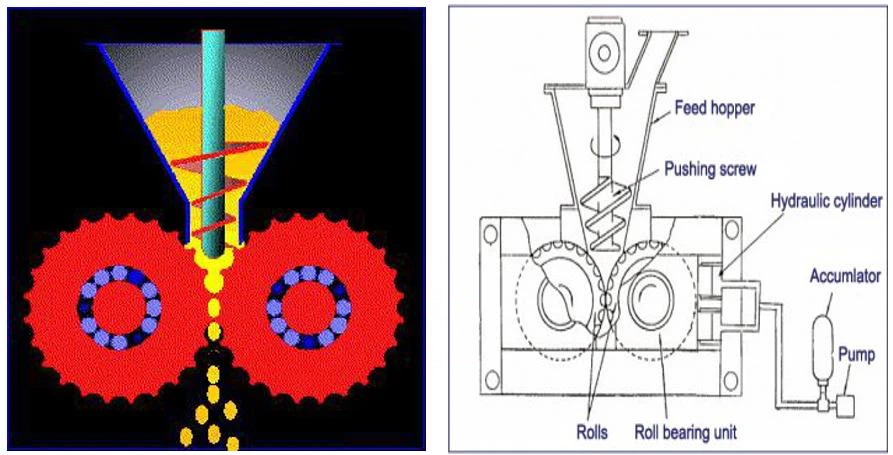

Hydraulic briquette press machine can press the fine powder into specified shape. The shape is formed by the hole on the rollers.

Introduction

Hydraulic briquette press machine has two rollers which is pressed by the hydraulic station. When fine powder passes the space between the two rollers, it will be pressed in to the briquettes. The final briquette has high strength and hardness. It is not easily broken.

Working Principle

In order to meet the requirement of materials’ molding, prepress screw is driven by electromagnetic speed regulating motor. Type of regulating speed is manually operated. According to condition of ball molding, User can change prepress machine’s rotating speed properly to reach max capacity. ball molding rate and capacity. After screening compressed material by screening machine, finished qualified briquettes are on the screening machine. Minus mesh material can return back to hopper for mixing with new materials for another compression.

Rollers

Briquette socket’s shape in briquette machine’s roller sheet can be chosen widely according to user’s need. The ball’s shapes include pillow shape, semi-cylinder shape, egg shape, bar shape, thin skin pill shape, walnut shape, apricot core shape, small particle shape and so on.

(1) High quality forging alloy(Cr9Mo2)

(2) Whole-quenching process and tempering process.

(3) Multiple flaw detection tests to ensure that the product is qualified

(4) High hardness, high wear resistance, long service life

Customer Site