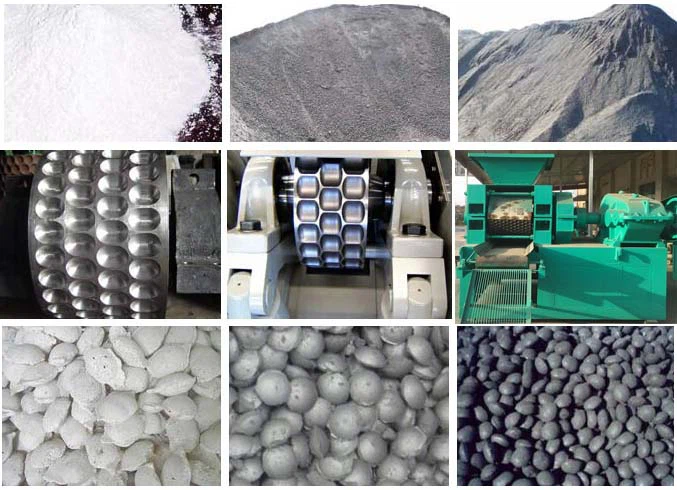

Magnesium Briquette Machine

Send InquiryIntroduction

Magnesium briquette machine has two rollers which is pressed by the hydraulic station. When fine powder passes the space between the two rollers, it will be pressed and be shaped into the briquettes. By rotation of the two rollers, it will then drop down. Magnesium briquette machine is mainly used for pressing briquettes of magnesium oxide, and the finished product can be used for the production of metal magnesium.

Application

Magnesium briquette machine is one kind of high-pressure briquette machine. It is mainly applied in the coal, mining, metallurgy, fire-resistant materials, construction materials and other light metal industries. The material pressed into briquette is convenient for transportation and has much less environmental pollution. At the same time, the industrial value increases a lot.

Advantages

1) High energy saving: Energy saving: electricity consumption of per ton is half of that normal briquette press machine.

2) High environmental protection: The magnesium briquette machine has high force, which means high briquette rate production, less powder.

3) High linear pressure: linear pressure can be 300kn/cm, the final briquette has high strength and cannot be broken easily during the transportation.

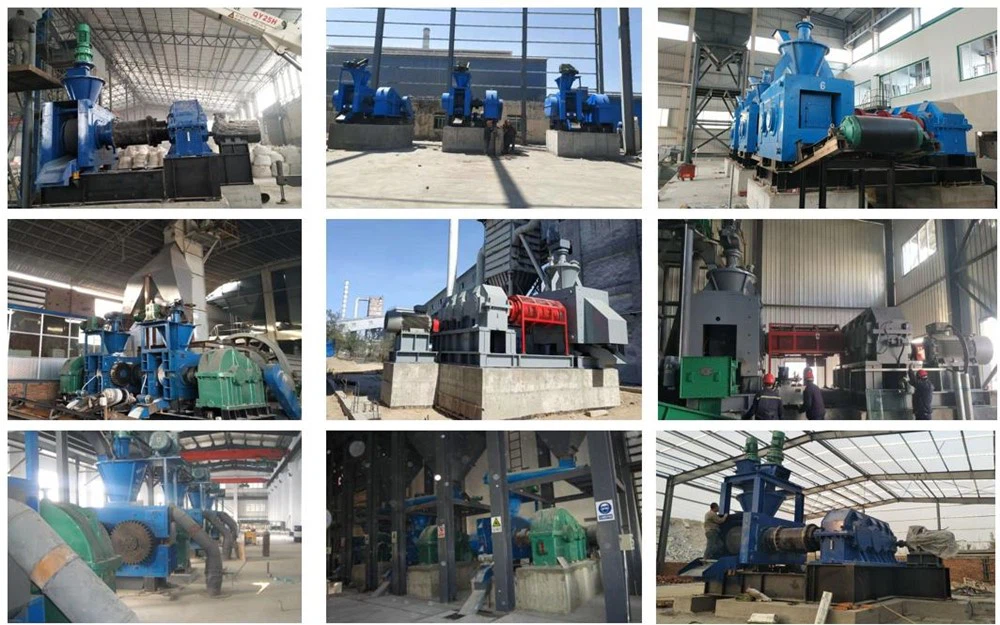

Customer Site

FAQ

Q1: What is the material of the rollers:

A1: The raw material is 9Cr2Mo, one of the hard material with high tolerance.

Q2: What is the capacity of the briquette machine?

A2: The Capacity of the briquette machine varies from 200kg to 25 tons per hour.

Q3: How long can the roller be working?

A3: The roller is made of hard material, the service life of the rollers depends on the type of raw material for briquette. Normally one pair of roller can last for 12 months.

Q4: What is the pressure between the two rollers?

A4: Normally the pressure between the two rollers is 6-10 tons.