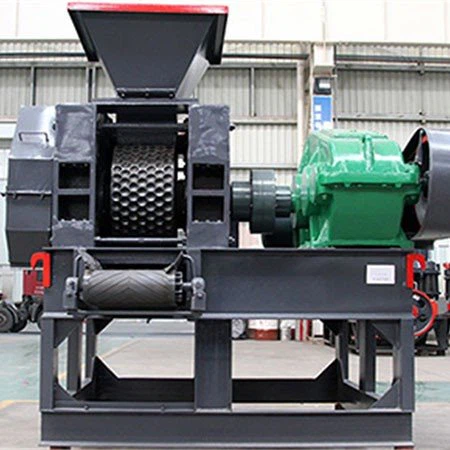

Hydraulic Briquette Maker

Hydraulic briquette press machine is the equipment which can turn powdery product into briquette with all kinds of shape.

Introduction

Hydraulic briquette Maker has two rollers which is pressed by the hydraulic station. When fine powder passes the space between the two rollers, it will be pressed in to the briquettes. With the rotation of the rollers, the briquettes fall down to the belt conveyor. The Hydraulic Briquette Maker is widely used in metallurgy and chemical industry.

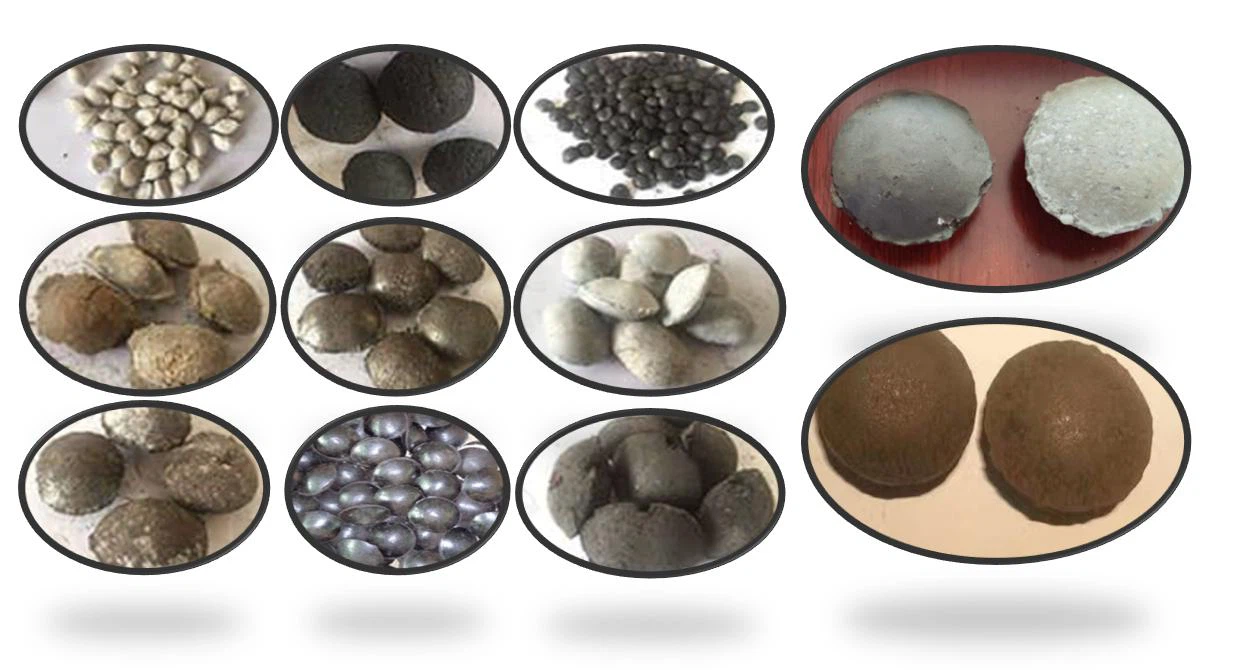

Application

Hydraulic briquette maker is the equipment which compress powder material into briquette. It is widely used. It can pelletize the following materials into briquette, grain or ball such as aluminum powder, activated carbon, alumina, bauxite, caustic soda, charcoal, clay, coke, iron scurf, coal, cryolite, fertilizer, plastic, limestone, pigment, urea, potassium salt….and so on. The purpose of compression is to reduce powder dust, control volume, being easy for next use and transport. It is designed to compress dry powder into briquette used in process of Pidgeon’s magnesium reduction.

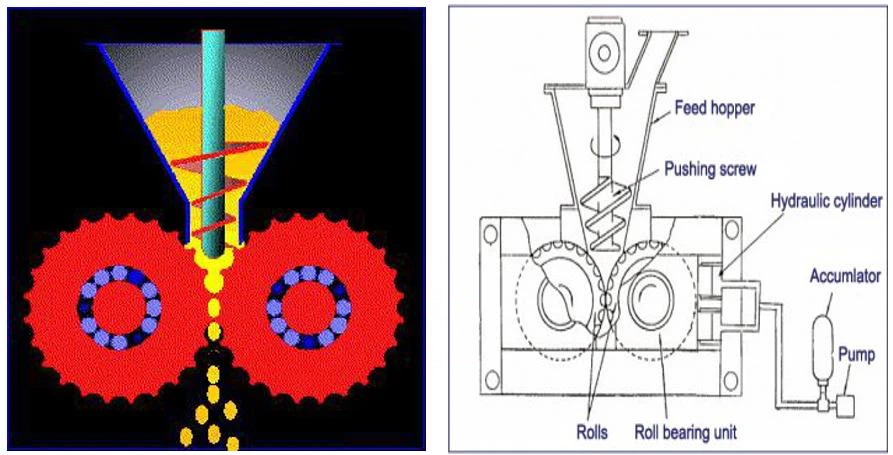

Working Principle

(1) Fine powder fed into the pre-press device

(2) The powder will be press into the space of the double rollers by screw.

(3) Double rollers are pressed by the hydraulic cylinder.

(4)Powder is press with high force and drop down to the vibrating screen.

Technical Parameters

Model | LYQ0.5 | LYQ1.0 | LYQ1.5 | LYQ2.0 | LYQ3.0 | |

Diameter of roller | Φ299 | Φ367 | Φ367 | Φ399.5 | Φ522 | |

No. of slots in roller surface | 108 | 200 | 200 | 240 | 300/360 | |

Width of roller surface | 180 | 183 | 183 | 252 | 196 | |

Type& quantity of bearing | 7522 | 2097730 | 2097730 | 2097736 | 2097744 | |

4sets | 4sets | 4sets | 4sets | 4sets | ||

Capacity (kg/h) | 500 | 1000 | 1500 | 2000 | 3000 | |

Main motor | Model | YCT250-4A | YCT315-4AB | YCT315-4A | BY67315-413 | Y250M-4 |

Power | 18.5KW | 37KW | 45KW | 45KW | 55KW | |

Pre-press motor | Model | YCT200-4B | YCT225-4A | YCT225-4A | YCT225-4A | YCT225-4A |

Power | 7.5KW | 11KW | 15KW | 15KW | 15KW | |

Screen's motor | Power | 0.6KW | ||||

Oil pump motor | Model | DZB0.8 | DZB2.2 | |||

Power | 1.8KW | |||||

Main reducer | ZA650-48.57 | ZQ850-48.57 | ZQ850-48.57 | ZQ1000 | ZS1250 | |

Pre-press reducer | WHC15-31.5 | WHC18-31.5 | WHC18-31.5 | WHC21-31.5 | WHC-160 | |

Model | DBD0.8 | DBD0.8 | DBD0.8 | DBD0.8 | DZB2.2 | |

Rated flow | 0.8L/min | 0.8L/min | 0.8L/min | 0.8L/min | 2.2L/min | |

Rated pressure | 800kgf/c㎡ | 800kgf/c㎡ | 800kgf/c㎡ | 800kgf/c㎡ | 800kgf/c㎡ | |

Recommend working pressure | 85-120 kgf/c㎡ | 120-150 kgf/c㎡ | 120-150 kgf/c㎡ | 140-160 kgf/c㎡ | 140-160 kgf/c㎡ | |

Diameter | Φ150 | Φ200 | Φ200 | Φ200 | Φ160 | |

Max pushing pressure | 42T | 94T | 94T | 120T | 128T | |

Customer Site

Description of Hydraulic Briquette Maker

Q1: What is the material of the rollers:

A1: The raw material is 9Cr2Mo, one of the hard material with high tolerance.

Q2: What is the capacity of the briquette machine?

A2: The Capacity of the briquette machine varies from 200kg to 25 tons per hour.

Q3: How long can the roller be working?

A3: The roller is made of hard material, the service life of the rollers depens on the type of raw material for briquette. Normally one pair of roller can last for 12 months.

Q4: What is the pressure between the two rollers?

A4: Normally the pressure between the two rollers is 6-10 tons.