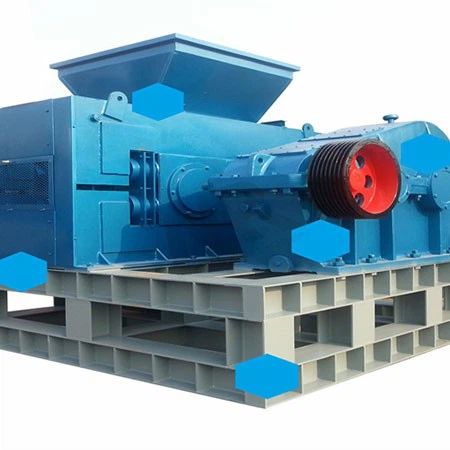

Multifunctional Briquette Making Machine

Briquette making machine is the equipment which can press the fine powder into specified shape.

Introduction

Multifunctional briquette making machine has two rollers which is pressed by the hydraulic cylinder. The two rollers will press the powder when the powder passed from the space, and then drop down with the briquette. The shape of the briquette is decided by the shape of hole in on the two rollers.

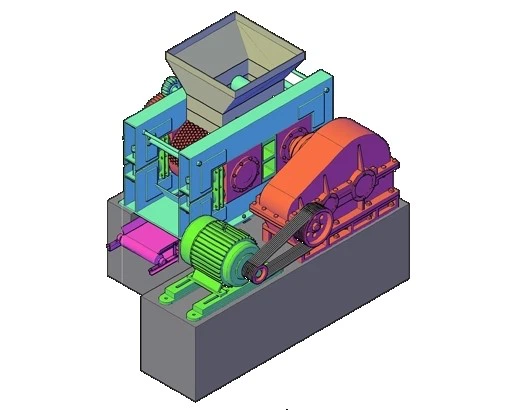

Working Principle

The raw material will be mixed with binder and the stickiness will increase, within the belt conveyor, it will be fed into the hopper of the briquette machine, with gravity, the powder will fall down to the space of the two rollers, with the pressure of the two rollers, the powder will then be formed in to specified shape according to the holes on the rollers. With the rotation of the rollers, the briquette will fall down and be screened. Only complete briquette will be transported to the final product pile.

Rollers

The rollers of briquette making machine has different types, The rollers are optimized according to the requirement of the customers. The material of the rollers normally adopts high hardness and wearing -resistant material.

(1) High quality forging alloy(Cr9Mo2).

(2) Whole-quenching process and tempering process.

(3) Multiple flaw detection tests to ensure that the product is qualified.

(4) High hardness, high wear resistance, long service life.

Technical Parameters

Model | MRL-4 | MRL-6 | MRL-8 | MRL-10 | MRL-15 |

Capacity | 3-4t/h | 6t/h | 8t/h | 10t/h | 15t/h |

Roller width | 250mm | 240mm | 220mm | 300mm | 336mm/400mm |

Roller diameter | 360mm | 400mm | 450mm | 500mm | 650mm |

Power | 7.5 kW | 11 kW | 18.5kW | 22kW | 37kW |

Reducer | ZQ350 | ZQ400 | ZQ500 | ZQ500 | ZQ650 |

Pressure type | Mechincal | Mechincal | Mechincal | Hydraulic | Hydraulic |

Roller material | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn |

9Cr2Mo | 9Cr2Mo | 9Cr2Mo | 9Cr2Mo | 9Cr2Mo | |

wear- resistant alloy | wear- resistant alloy | wear- resistant alloy | wear- resistant alloy | wear- resistant alloy | |

Roller assemble | Split- clamp type | Split- clamp type | Split- clamp type | Temper assembly | Temper assembly |

Hardness of roller | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC | 52-62 HRC |

Pressure structure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure |

Dimension(mm) | 1200x1150 x1835 | 1400x1298 x2125 | 1700x1510 x2200 | 2000x1960 x2440 | 2188x1972 x1670 |

Weight(kg) | 2100 | 2300 | 2750 | 5800 | 7600 |

Model | MRL-20 | MRL-30 | MRL-40 | Note |

Capacity | 20t/h | 30t/h | 40t/h | According to material |

Roller width | 428mm/500mm | 500mm | 00mm | |

Roller diameter | 750mm | 850mm | 1000mm | |

Power | 55kW | 90 kW | 110kW | |

Reducer | ZQ850 | ZQ1000 | ZQ1000 | standard configuration |

Pressure type | Hydraulic | Hydraulic | Hydraulic | patent |

Roller material | 65Mn | 65Mn | 65Mn | Casting |

9Cr2Mo | 9Cr2Mo | 9Cr2Mo | Forging | |

wear-resistant alloy | wear-resistant alloy | wear-resistant alloy | patent | |

Roller assemble | Temper assembly | Temper assembly | Temper assembly | patent |

Hardness of roller | 52-62 HRC | 52-62 HRC | 52-62 HRC | |

Pressure structure | Four-rollers double pressure | Four-rollers double pressure | Four-rollers double pressure | patent (four rollers) |

Dimension(mm) | 2660x2300x1750 | 2965x2450x1980 | 3065x28850x2220 | |

Weight(kg) | 9000 | 15500 | 25000 |

Customer Site

Tools for Maintenance

FAQ

Q1: What is the material of the rollers?

A1: The raw material is 9Cr2Mo, one of the hard material with high tolerance.

Q2: What is the capacity of the briquette machine?

A2: The Capacity of the briquette machine varies from 200kg to 25 tons per hour.

Q3: How long can the roller be working?

A3: The roller is made of hard material, the service life of the rollers depends on the type of raw material for briquette. Normally one pair of roller can last for 12 months.

Q4: What is the pressure between the two rollers?

A4: Normally the pressure between the two rollers is 6-10 tons.