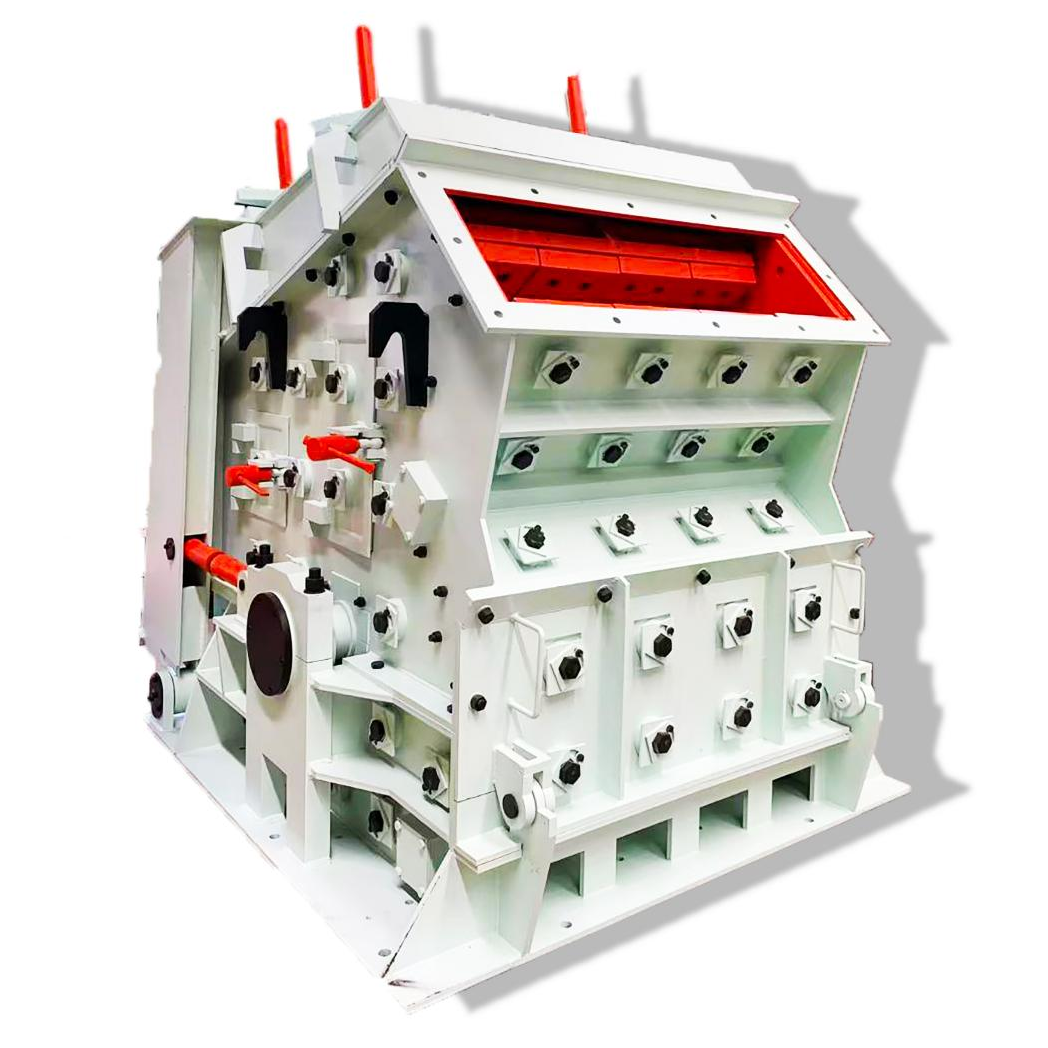

PF High-quality Crusher Machine

PF Series Impact Crusher is a high-efficiency impact crushing device specifically designed for medium-hard and lower hardness materials.

Application

PF Series Impact Crusher is a high-efficiency impact crushing device specifically designed for medium-hard and lower hardness materials. Its core advantage lies in the proven heavy-duty rotor structure, which ensures stable operation while achieving a high reduction ratio, excellent finished product particle shape control, and low operating costs. Consequently, it has become one of the preferred equipment for secondary or tertiary crushing processes in fields such as mining, building materials, metallurgy, and chemical engineering.

Working Principle

The motor of the impact crusher drives the rotor shaft to rotate at high speed via V-belts. Material entering the machine is first struck powerfully by the hammers on the rotor, accelerated, and thrown against the primary impact plate for crushing. The crushed material then rebounds from the impact plate back into the hammer action zone to be struck again. This “impact-rebound-re-impact” process cycles repeatedly within the machine.

The material subsequently passes through subsequent crushing chambers (entering the second and third chambers in sequence for three-chamber models), continuously being refined under multi-layered impacts and counter-blows. When the material size becomes smaller than the discharge gap between the hammers and the impact plate, it is discharged from the bottom of the equipment as the final product.

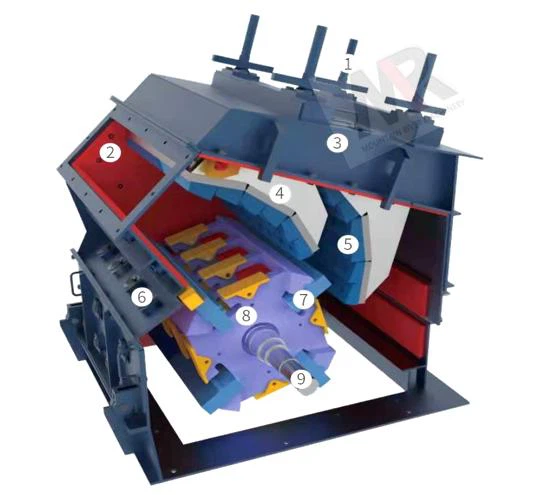

Main Structure

1. Adjustment Device | 2. Rack Liner | 3. Rear Rack | 4. Counter Rack | 5. Impact Liner |

6. Front Rack | 7. Blow Hammer | 8. Rotor | 9. Main Shaft |

Technical Parameters

Model | Rotor Specifications (mm) | Inlet Size (mm) | Feed Particle Size (mm) | Capacity (t/h) | Weight (t) |

PF1010 | Φ1050×1000 | 400×1080 | <350 | 50-80 | 11.4 |

PF1210 | Φ1250×1050 | 400×1080 | <350 | 60-120 | 14.2 |

PF1214 | Φ1250×1400 | 400×1430 | <350 | 80-160 | 15.8 |

PF1315 | Φ1300×1500 | 860×1520 | <350 | 120-260 | 19.3 |

Maintenance Procedures

1.Daily Operational Monitoring

Equipment operation should be smooth. If vibration levels rise abnormally, the machine must be stopped immediately for inspection and troubleshooting.

Worn hammers can be reversed for further use or replaced. After replacement, rotor balance must be ensured. Worn frame liners should be replaced promptly to prevent damage to the machine housing.

The condition of all fastening bolts must be checked before each start-up.

2.Lubrication Maintenance

Perform lubrication regularly.

The type of lubricant should be selected based on the operating environment and ambient temperature. Lithium-based grease is recommended.

Replenish grease to the bearings every 8 hours of operation. Perform a complete grease change every 3 months. When changing the grease, clean the bearings with clean gasoline or kerosene. The filling amount should be approximately 50% of the bearing housing volume.