Raymond Mill & Ultrafine Mill Working Temperature Comparison

Introduction

In the use of mining equipment, Raymond mill machine and ultrafine grinding mill are two indispensable core grinding equipment, usually used for grinding non-metallic minerals with Mohs hardness ≥ 7 such as calcite, limestone, marble, quartz, talc and graphite.

In the actual production process, the temperature inside the mill will rise due to continuous operation. Due to the different working principles and internal structures of Raymond grinding mill and ultrafine grinding mill, the temperature rise inside the body will also be different. If the corresponding reliable temperature control method is not implemented, it will affect the characteristics of the material and increase the loss of the mill.

Temperature Source of Raymond Mill and Ultrafine Mill

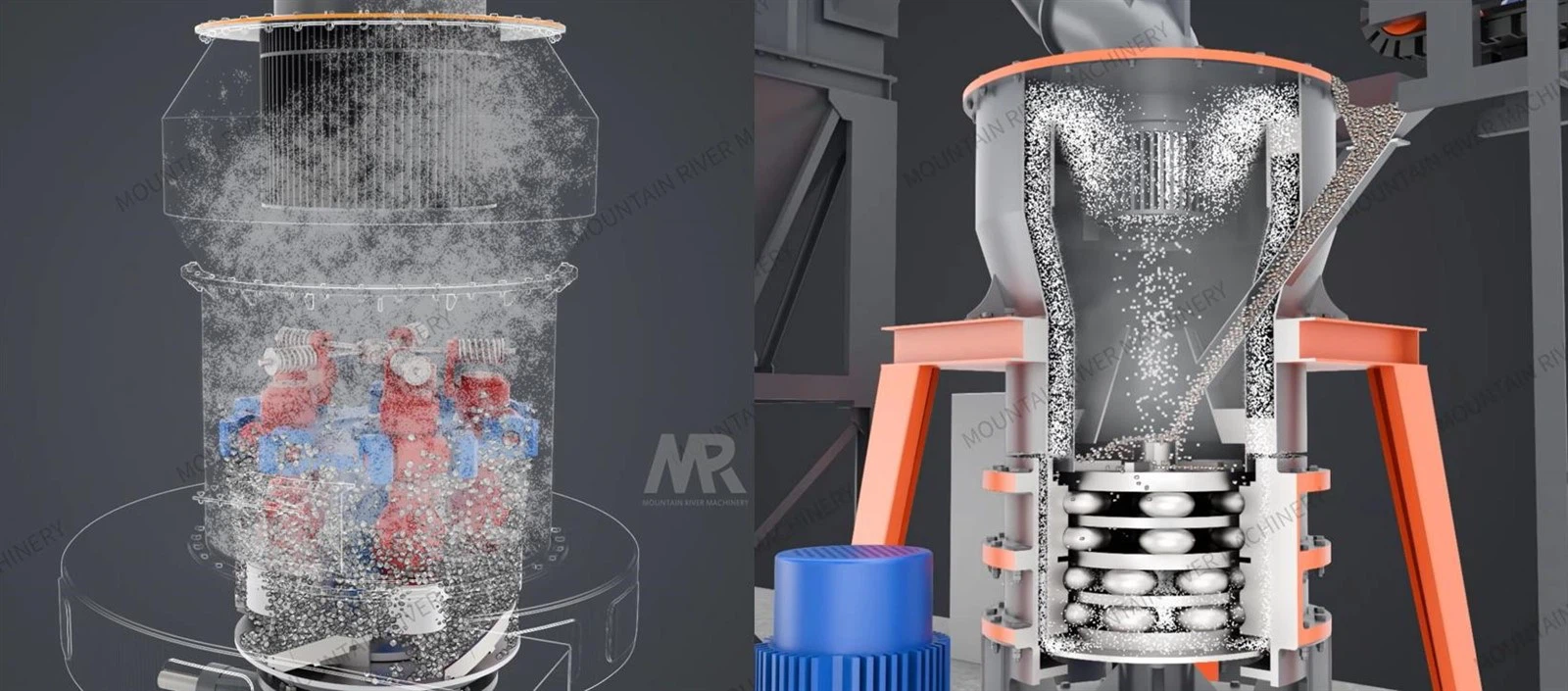

Working principle of Raymond mill :

When the material enters the Raymond mill pulverizer and falls onto the blade seat, it will be crushed by the high-speed rotating grinding roller and grinding ring under the pressure of interaction. Qualified powder will enter the pipeline to the powder collector through the powder selector to become the finished product.

Working principle of ultrafine grinding mill:

Multi-layer grinding roller and precise grading system, under the action of centrifugal force, the grinding roller exerts greater pressure to grind the material finer.

Reasons for temperature increase:

Frictional heat: When the grinding roller and grinding ring squeeze the material at high speed, friction will be generated, and the operation of the transmission system (such as bearings and gears) may increase the temperature by 60~100°C.

Airflow heating: When the high-pressure fan blows the powder, the air and powder particles flow at high speed and collide with each other, which will also generate heat.

Grinding itself heats up: When the material is ground, the crystal structure of the material will be destroyed and heat will be released. The harder the material, the more heat will be generated during grinding.

Temperature Characteristics

Raymond mill:

The working temperature is usually maintained in a low range, which is suitable for processing non-thermosensitive mineral materials such as limestone and barite.

During continuous operation, the continuous friction between the grinding roller and the material and the mechanical movement of the bearing will produce cumulative thermal effects, which may cause the temperature gradient of key components to rise. It is necessary to pay attention to the temperature rise of the bearing position and the contact surface of the grinding roller.

ultrafine grinding mill:

The working temperature of the ultrafine grinding mill is generally higher than that of the Raymond mill, which is mainly due to the higher hydraulic grinding pressure and more intense mechanical energy conversion.

When performing ultra-fine grinding, the exponential growth of the specific surface area of the material will significantly enhance the surface energy release effect, forming an obvious local high temperature zone in the grinding chamber. This heat accumulation phenomenon will directly affect the physical and chemical properties of the powder.

Effects of Rising Temperatures

Impact on materials:

High temperature increases the viscosity of fine particles, making them prone to agglomeration, reducing product dispersibility, and causing unstable moisture content in materials, affecting subsequent processes (such as granulation and tableting).

The oxidation rate of carbon materials such as activated carbon and graphite increases significantly under the influence of rising temperatures. Metal powders (such as aluminum powder) also oxidize at high temperatures, increasing the risk of explosion. Some minerals (such as gypsum) undergo crystal transformation at high temperatures, affecting product performance.

Impact on the main mill:

Under high temperature conditions, the viscosity of the lubricating grease in the bearing system will decrease significantly, resulting in weakened oil film strength. Long-term operation will shorten the bearing life. At the same time, rubber seals will age faster under continuous high temperature conditions.

From a process perspective, high-temperature airflow will disrupt the material movement trajectory, reduce classification efficiency, increase system energy consumption, and ultimately increase the comprehensive operation and maintenance costs of the mill.

How to Effectively Control Temperature?

Temperature control method of Raymond mill:

Air volume optimization and control: By accurately adjusting the system air volume and wind speed, an efficient airflow heat dissipation channel can be established to reduce the temperature of the grinding chamber. The key is to ensure that the air path is unobstructed and regularly clean the dust in the pipeline.

Special lubrication system upgrade: Select high-temperature resistant synthetic grease (such as polyurea-based or composite lithium-based grease), whose high temperature stability can reach more than 150°C, and establish a regular lubrication system.

Intelligent operation mode: Use PLC control system to implement intermittent operation strategy, and install temperature interlock device, which can automatically shut down for protection when the bearing temperature is too high.

Keep the air inlet open.

Temperature control method of ultrafine grinding mill:

Efficient cooling system integration: Add double-layer spiral water cooling jackets to the key parts of the grinding chamber and the powder selector, and keep the inlet and outlet temperature difference slightly changed. It is recommended to use a closed-loop cooling system with a PID temperature control module to achieve precise temperature control.

Inert gas protection system: Configure a high-purity nitrogen protection device to maintain the oxygen content in the grinding chamber <5%. The system should include a gas flow meter, a pressure sensor and an automatic air replenishment device to form a complete gas protection closed loop.

Intelligent feed control: Install an online material flow monitoring system. When the temperature exceeds the set threshold, the system automatically reduces the feed amount to ensure that the equipment operates in the optimal thermal balance state.